Tartary buckwheat dehulling device

A technology of tartary buckwheat and equipment is applied in the field of tartary buckwheat hulling equipment, which can solve the problems of low work efficiency, insufficient hulling, and inability to large-scale hulling operations, and achieve the effects of complete hulling and high hulling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

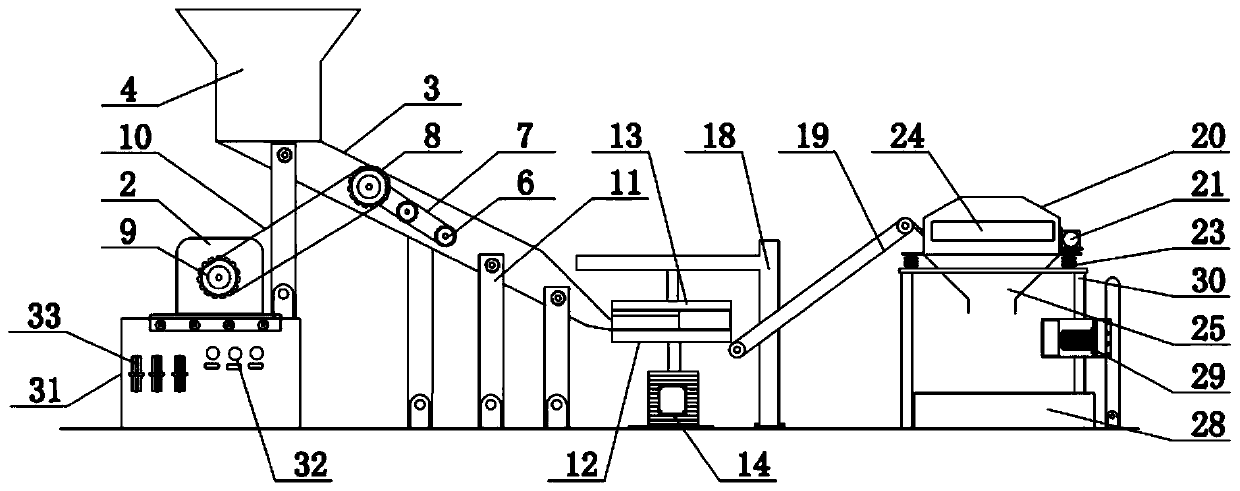

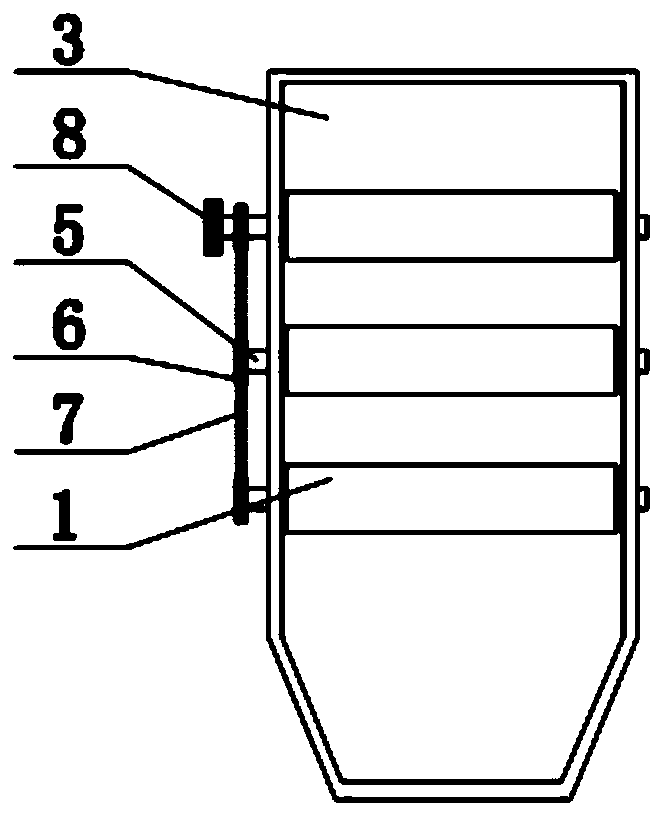

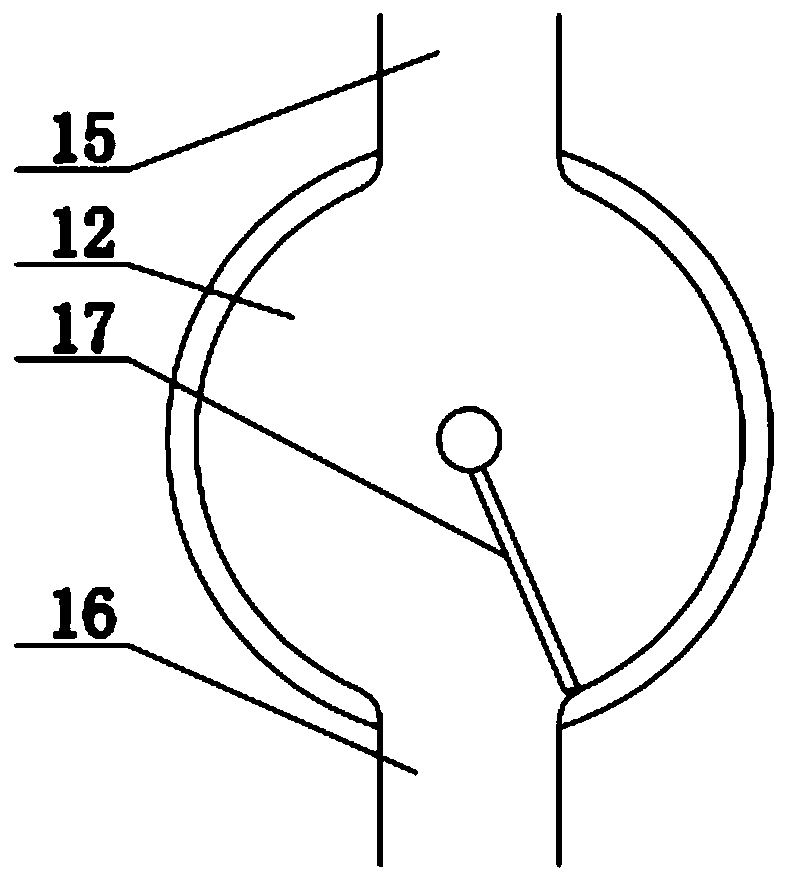

[0023] see figure 1 —4, a kind of tartary buckwheat shelling equipment, comprises rolling device, cracking device, dehulling device, and rolling device comprises rolling roller 1, starting motor 2, feeding chute 3, and feeding chute 3 one ends are fixedly connected with The feed pipe 4 and the feeding trough 3 are provided with multiple sets of rolling rollers 1, both ends of the rolling rollers 1 are fixedly connected to the rotating shaft 5, and the rotating shaft 5 is rotationally connected with both sides of the feeding chute 3, and the feeding chute 3 The rotating shaft 5 on the outer edge of one side is fixedly connected with a driving gear 6, and the driving gears 6 are connected by a No. 1 chain 7, wherein one group of rotating shafts 5 is fixedly connected with a driven gear 8 on the outer side of the driving gear 6. The motor 2 is fixedly connected with the driving gear 9, the driving gear 9 and the driven gear 8 are connected by the second chain 10, the distance bet...

Embodiment 2

[0028] see figure 1 —4, a kind of tartary buckwheat shelling equipment, which is basically the same as the first embodiment, furthermore, the starter motor 2 is installed on the high platform 31, and the fixed bracket 11 connected with the feeding chute 3 is also fixedly connected to the high platform 31 On the top, the fixed bracket 11 is raised by the high platform 31, so that the feeding trough 3 is a downward inclined structure, so that the overall structure of the device is arranged reasonably, and the use of structural materials of the device is reduced;

[0029] One side of high platform 31 is provided with many groups of control buttons 32, control gate 33, work indicator light, and control button 32 is provided with the control button 32 of control drive motor, the control button 32 of control rotation motor 14, the control button 32 of control vibration motor 21 , the control gate 33 is mainly used for the overall power transmission of the device, including a control...

Embodiment 3

[0035] see figure 1—4, a kind of tartary buckwheat shelling equipment, its working principle is: when in use, tartary buckwheat is fed in from the feed pipe 4, so that it falls into the feeding chute 3, because the feeding chute 3 is inclined, so it can be used Gravity makes the tartary buckwheat slide downwards. At the same time, the starter motor 2 drives the driven gear 8 and the driven gear 6 to rotate through the No. 2 chain 10, and then drives all the rolling rollers 1 to rotate through the No. 1 chain 7. When rotating, The tartary buckwheat can be transported at the same time as the initial crushing of the shell. After the crushing, it is transported between the rotating sand table 12 and the stationary sand table 13 through the feeding trough 3, and the rotating sand table 12 is driven by the rotating motor 14 to rotate. During the rotation process, the shell of the broken tartary buckwheat is separated again, and the rotating sand disc 12 will drive the tartary buckwh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com