Method for removing mutton smell of mutton fat

A technology of suet oil and lemon essential oil, applied in the direction of edible oil/fat, food science, application, etc., to achieve the effect of improving utilization rate, easy operation and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

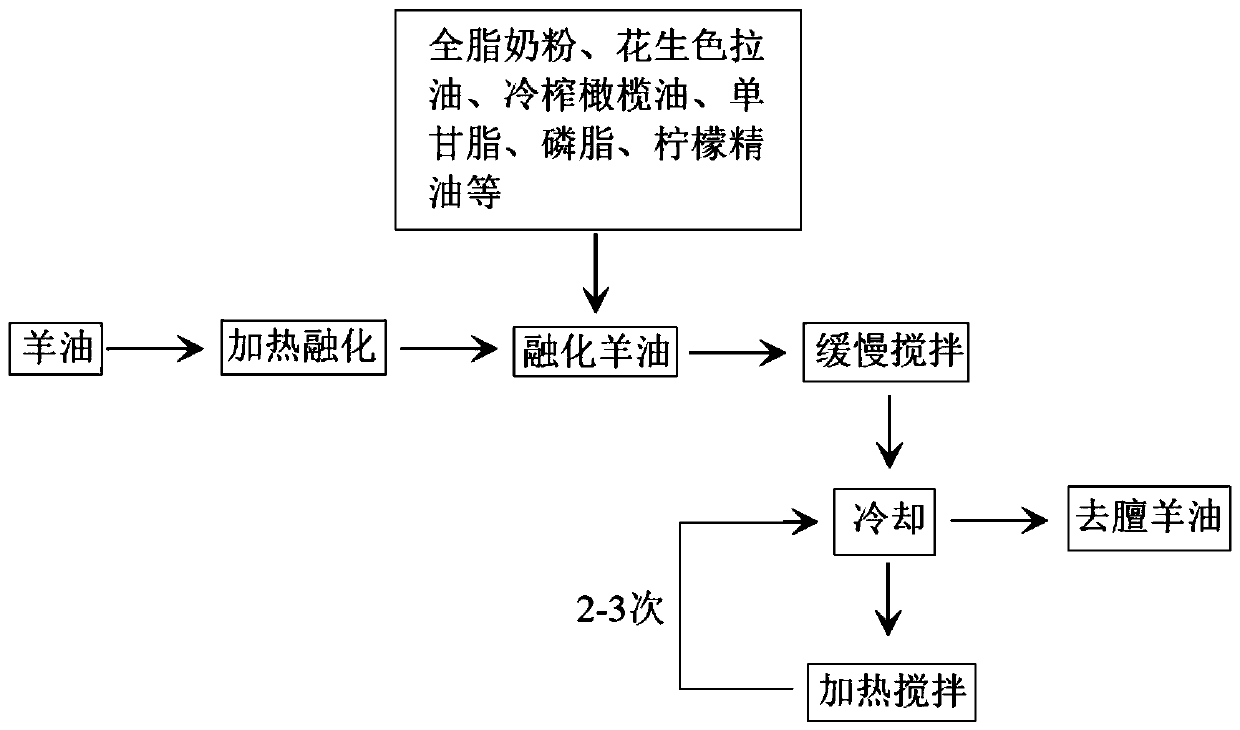

[0023] In the present embodiment, the method for sheep oil to remove mutton comprises the following steps:

[0024] (1) Take 1000g of refined suet, put it in a 70°C water bath, and heat slowly until it completely melts;

[0025] (2) After the suet is completely melted, add 5g of whole milk powder, 200g of peanut salad oil, 150g of cold-pressed olive oil, 5g of monoglyceride, 0.1g of phospholipid, 8mg of lemon essential oil, etc. into the completely melted suet. Stir slowly for 5 minutes, stop stirring, and cool at 4°C for 30 minutes.

[0026] (3) Heat up the material obtained in step (2) to 70° C., repeat heating, stirring and cooling for 2-3 times, stop stirring, and let the mutton oil cool naturally.

[0027] (4) The obtained mutton oil basically does not feel the smell of mutton, and is in a soft solid state, light yellow, with a delicate smell, and is suitable for making camellia oleifera and pastry.

[0028] The invention adopts pure natural raw materials and utilizes t...

Embodiment 2

[0030] In the present embodiment, the method for sheep oil to remove mutton comprises the following steps:

[0031] (1) Take 100kg of refined mutton fat, put it into a pot, turn on a low heat (do not exceed 150°C), and heat slowly until completely melted;

[0032] (2) After the sheep fat is completely melted, add 800g whole milk powder, 25kg peanut salad oil, 20kg cold-pressed olive oil, 600g monoglyceride, 10g phospholipid, 0.8g lemon essential oil, etc. to the completely melted sheep oil, Stir slowly for 5 minutes, stop stirring, and cool at 4°C for 30 minutes.

[0033] (3) Heat up the material obtained in step (2) to 80° C., repeat heating, stirring and cooling for 2-3 times, stop stirring, and let the mutton oil cool naturally.

[0034] (4) The obtained mutton oil basically does not feel the smell of mutton, and is in a soft solid state, light yellow, with a delicate smell, and is suitable for making camellia oleifera and pastry.

[0035] The invention adopts pure natura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com