Preparation for reducing arsenic content in rice grains and preparing method and application method thereof

A technology for rice grains and preparations, applied in the directions of botanical equipment and methods, applications, biocides, etc., can solve the problems of affecting the yield of rice, increase the difficulty of operation, difficult to grasp, etc., and achieves the promotion of rice growth, no toxic and side effects, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The composition and production process of the preparation for reducing mercury content in rice grains are as follows: add 1L of water to the reaction kettle, adjust the water temperature to 50-60°C, and add 20g / L, L-selenomethionine 25g / L, cystathionine 40g / L, mannitol chelated calcium 150g / L, potassium pyrophosphate 100g / L, ethoxylated polytrisiloxane 5g / L And polyaspartic acid 15g / L, after adding each component, react at constant temperature (50-60°C) for 30min; until polyaspartic acid as the last component is added, react at constant temperature at 50-60°C for 30min.

[0036] After all components are added, the reaction product is cooled, filtered (through a 2500-mesh filter), sterilized (heated at 121°C for 20 minutes), and filled to obtain the finished product.

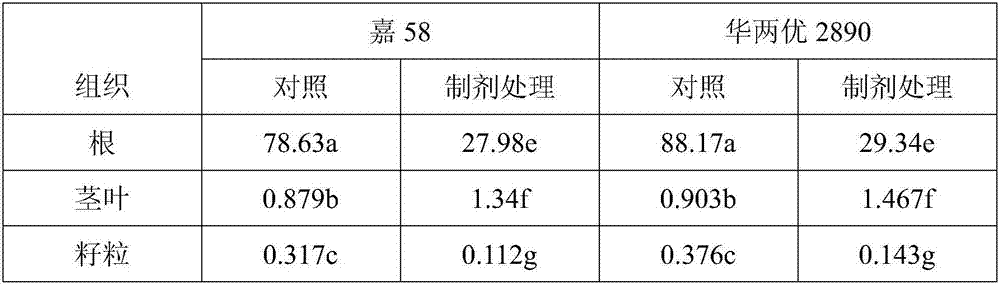

[0037] The above-mentioned preparations were used to carry out the plot test. The contaminated soil test plot [volume, 1m (length) × 1m (width) × 0.4m (height)] was built with cement. The soil used was co...

Embodiment 2

[0044] The composition and production process of the preparation for reducing mercury content in rice grains are as follows: add 1L of water to the reaction kettle, adjust the water temperature to 50-60°C, and add 25g / L, L-selenomethionine 23g / L, cystathionine 50g / L, mannitol chelated calcium 200g / L, potassium pyrophosphate 150g / L, ethoxylated polytrisiloxane 7.5g / L L and polyaspartic acid 15g / L, after adding each component, react at constant temperature for 30min. After adding polyaspartic acid as the last component, react at a constant temperature of 50-60° C. for 30 minutes.

[0045] After all components are added, the reaction product is cooled, filtered (through a 2500-mesh filter), sterilized (heated at 121°C for 20 minutes), and filled to obtain the finished product.

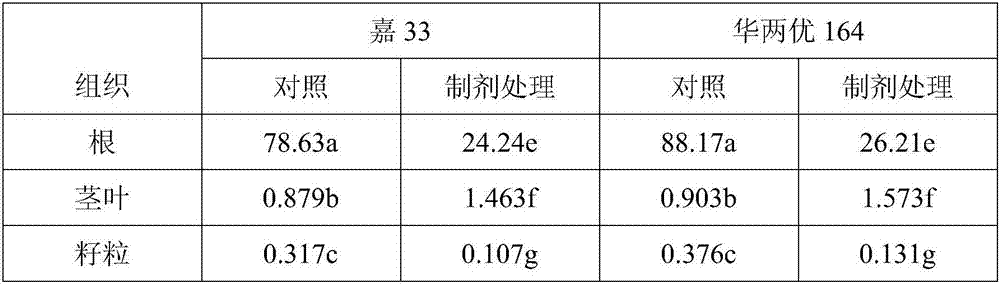

[0046] The above-mentioned preparations were used to carry out the plot test. The contaminated soil test plot [volume, 1m (length) × 1m (width) × 0.4m (height)] was built with cement. The soil used was ...

Embodiment 3

[0053] The composition and production process of the preparation for reducing mercury content in rice grains are as follows: add 1L of water to the reaction kettle, adjust the water temperature to 50-60°C, and add 22g / L, L-selenomethionine 25g / L, cystathionine 45g / L, mannitol chelated calcium 175g / L, potassium pyrophosphate 125g / L, ethoxylated polytrisiloxane 10g / L and polyaspartic acid 10g / L, each component was added and reacted at a constant temperature for 30 minutes; until the last component of polyaspartic acid was added, it was reacted at a constant temperature of 50-60°C for 30 minutes.

[0054] After all components are added, the reaction product is cooled, filtered (through a 2500-mesh filter), sterilized (heated at 121°C for 20 minutes), and filled to obtain the finished product.

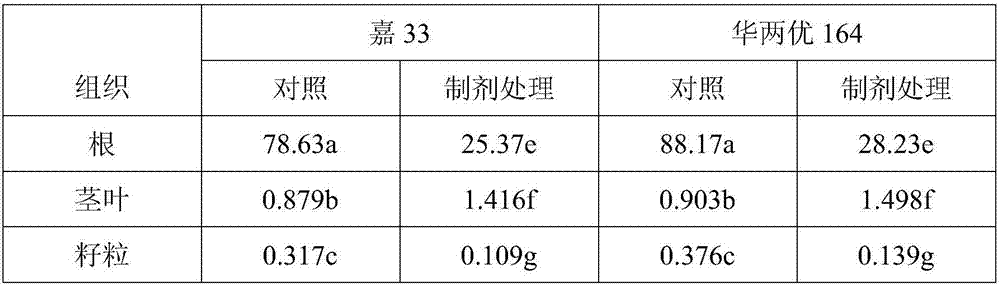

[0055] The above-mentioned preparations were used to carry out the plot test. The contaminated soil test plot [volume, 1m (length) × 1m (width) × 0.4m (height)] was built with cement. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com