A preparation method of a lithium-ion battery with improved high-voltage low-temperature discharge and cycle performance

A lithium-ion battery, cycle performance technology, applied in battery electrodes, secondary batteries, electrode manufacturing, etc., can solve the problems of low-temperature discharge performance and poor cycle performance, and achieve improved low-temperature discharge performance, low impedance, and reduced compaction density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

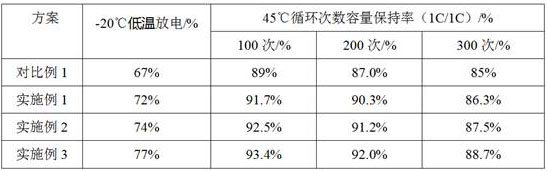

Examples

specific Embodiment approach 1

[0011] DETAILED DESCRIPTION OF THE INVENTION A method of preparing a lithium ion battery increasing high voltage low temperature discharge and cycle performance, the preparation method steps are as follows:

[0012] Step 1: A negative electrode slurry A having a thickness of 170 um to 240 um is applied to the negative electrode collector length, the negative slurry A, from the negative electrode main material, high ratio surface area (180 ~ 800m) 2 / g) Conductant, CMC, SBR, modified acrylic adhesive according to 96.1% ~ 97.3%: 0.5% ~ 1.0%: 0.96% ~ 1.5%: 0.3% ~ 1.19%: 0.3% ~ 1.19% mass composition composition ;

[0013] Step 2: Apply a negative slurry B having a layer of thickness of 170 um to 240 um on the negative electrode concentration fluid, from the negative electrode main material, low specific surface area (30 ~ 100m) 2 / g) Conductant, CMC, SBR consists of 96.1% to 97.3%: 0.5% to 1.0%: 1.2% ~ 1.5%: 1.0% ~ 1.4% mass percentage;

[0014] Step 3: Roller Pressure → Subthere. ...

specific Embodiment approach 2

[0016] DETAILED DESCRIPTION OF THE INVENTION A method of preparing a lithium ion battery increasing high voltage low temperature discharge and cycle performance, in step one, the specific method of formula A is: (1) 20 % ~ 50% of CMC and high-proportional area conductive agents are premixed in advance; (2) Add 20% to 30% negative electrode main material and 30% to 40% of CMC; (3) Add 25% to 30% negative electrode Materials and 10% to 50% of CMC; (4) Add 25% to 30% negative electrode main materials and modified acrylic binders; (5) add 10% to 30% negative electrode main material; (6) final One step will join the SBR.

specific Embodiment approach 3

[0017] DETAILED DESCRIPTION OF THE INVENTION 3: A method for improving a lithium ion battery having a high voltage low temperature discharge and cycle performance, in step two, the negative slurry B specifically formulated method: (1) 10 % ~ 30% CMC and low-specific surface area conductive agent advance mixed; (2) Add 20% to 30% negative electrode main material and 40% to 50% of CMC; (3) add 25% to 30% negative electrode Materials and 20% to 50% of CMC; (4) Add 25% to 30% negative electrode main materials; (5) add 10% to 30% negative electrode main material; (6) the last step adds SBR to all.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com