Waste oil treating device for smoke exhaust ventilator

A range hood and oil treatment technology, applied in the field of range hood waste oil treatment devices, can solve the problems of high viscosity of waste oil, troublesome waste oil treatment, blockage of the sewer, etc., to increase the contact area, speed up the oil collection speed, Avoid the effect of waste oil flowing down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

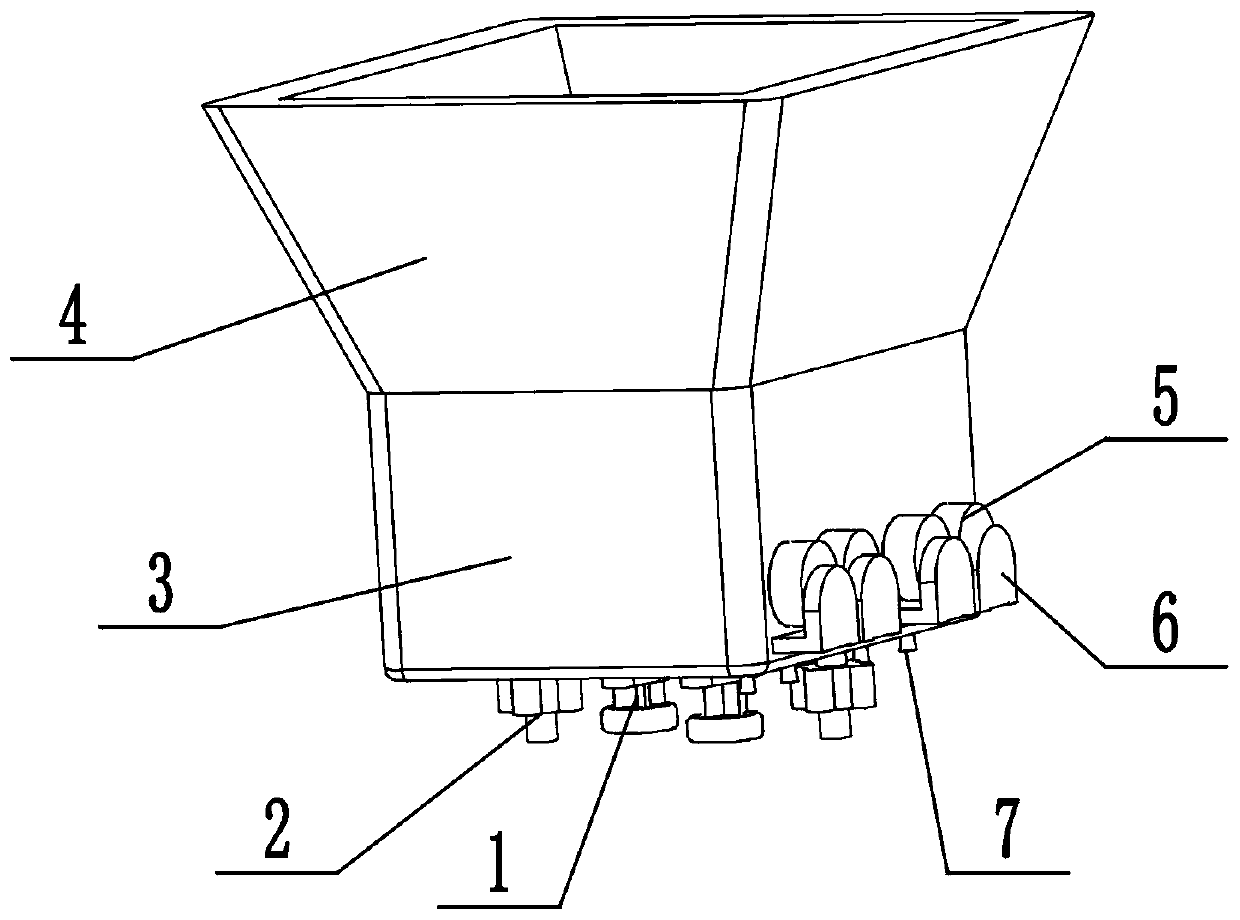

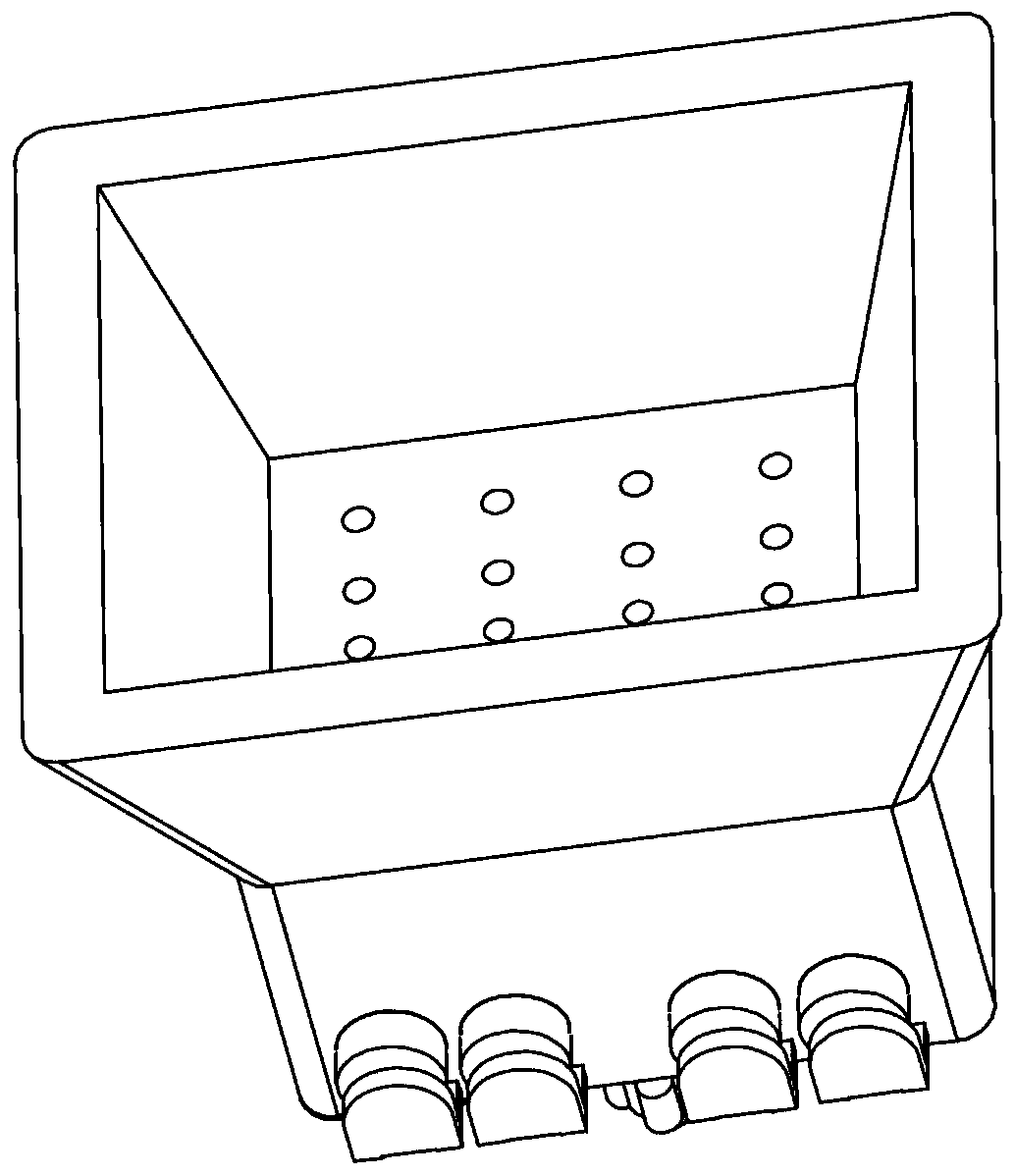

[0023] A range hood waste oil treatment device is composed of a negative pressure generator 1, a mounting nut 2, a waste oil treatment box 3, an oil collection box 4, a waste oil collector 5, an oil collection limit plate 6, and a limit pin 7 , an oil collecting plate 8 and a limit pin spring 9, the negative pressure generator 1 is installed in the waste oil treatment box 3, the oil collection box 4 is installed on the top of the waste oil treatment box 3, and the The waste oil collector 5 is mounted on the waste oil processing box 3, the oil collecting limit plate 6 is mounted on the waste oil processing box 3, and the oil collecting limit plate 6 is mounted on the waste oil collector 5, the mounting nut 2 fixes the waste oil treatment box 3 and the waste oil collector 5 together, the stop pin 7 is fitted on the waste oil treatment box 3, and the stop pin 7 Installed below the oil collecting limit plate 6, the limit pin spring 9 is fitted on the limit pin 7, the oil collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com