An open-pit end side pressure coal filling mining system

An end-to-end, open-air technology, applied in the fields of backfill, mining equipment, earth-moving drilling, etc., can solve the problems of difficult slope management, waste of coal resources, affecting the coal recovery rate, etc., to reduce production costs and labor intensity of workers. , Improve production efficiency and production safety, and maintain the effect of slope stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention provides an open-pit end-side pressure coal filling mining process, which can not only realize the recovery of a large amount of coal resources, but also reduce surface subsidence, and ensure the safety of the stope and the stability of the slope.

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

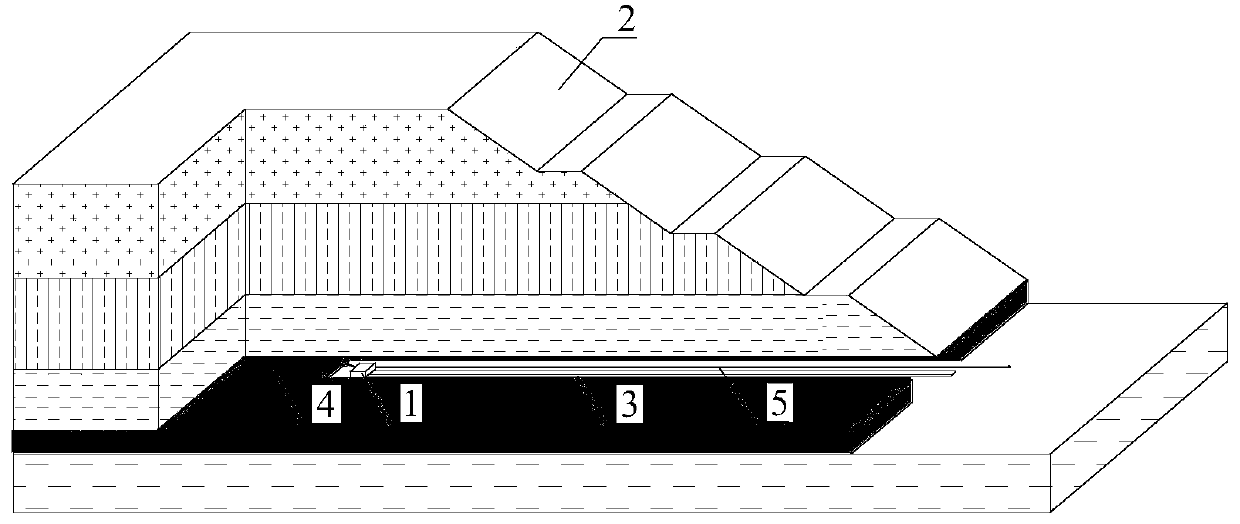

[0037] The present invention is an open-pit end side pressure coal filling mining system, such as figure 1 , 2 As shown, it has the following composition: the roadheader 1 automatically excavates the roadway 3 under the end-side steps 2, and the mining end-side is pressed into coal 4. The coal is loaded into the middle slide by the roadheader 1 rake and transferred to the belt conveyor, and is transported by the belt conveyor Transported out of the roadway 3, the articulated mechanical arm of the roadheader 1 is connected to the outlet end of the filling pipeline, and is continuously advanced with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com