Composite rolling shock isolation support

A technology of rolling shock isolation and backing plate, which is applied in the direction of earthquake resistance, building components, building types, etc., can solve the problems of poor living comfort, backwardness, and huge energy consumption, and achieve the effects of simple installation and construction, reduced damage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

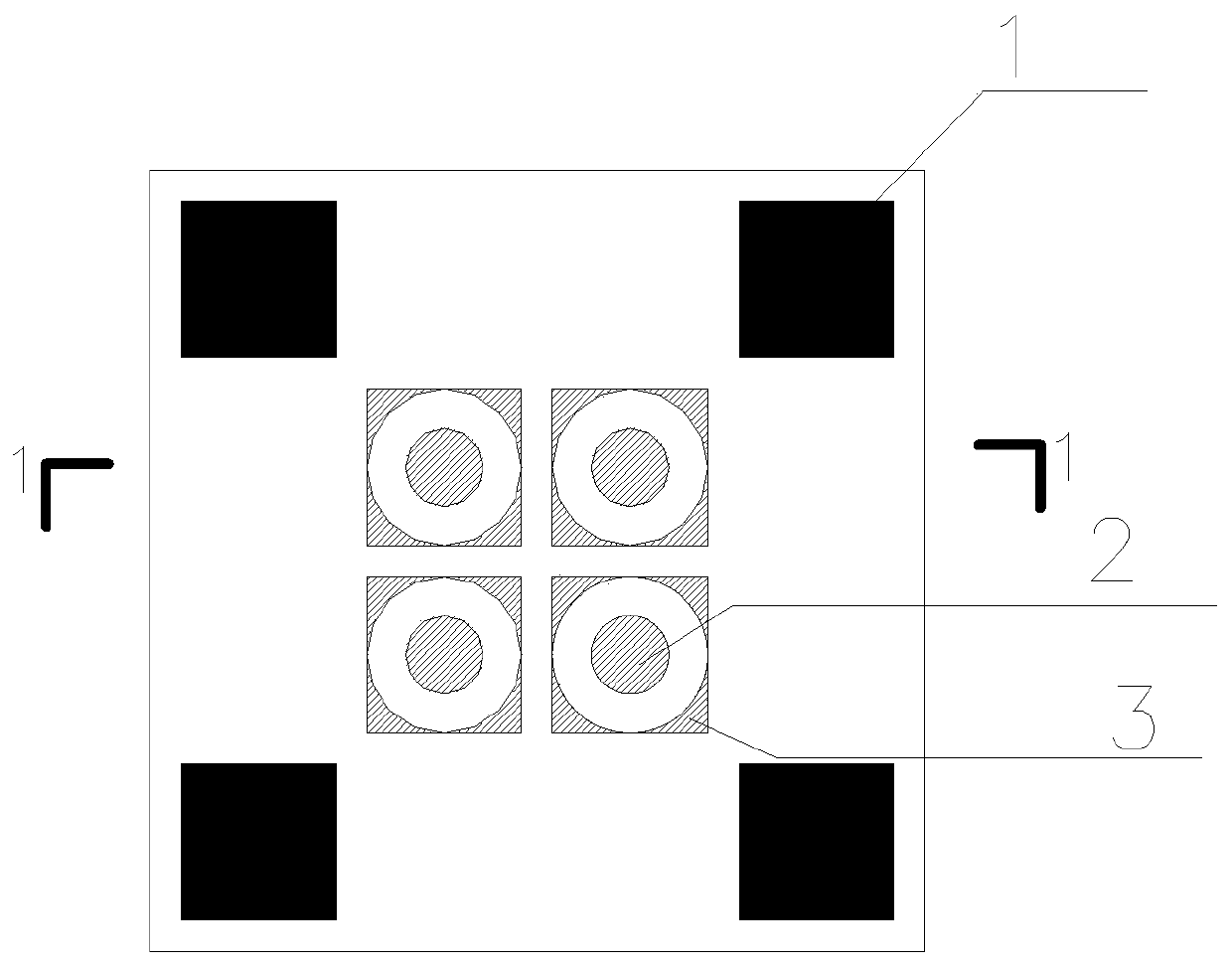

[0018] exist figure 1 and figure 2 In the shown schematic diagram of the present invention, the lower surface of the upper backing plate 4 is provided with four upper backing plate grooves 3-1, and the upper surface of the lower backing plate 5 is provided with four lower backing plate grooves 3-1. 2. The position of the groove of the upper backing plate corresponds to the groove of the lower backing plate. The groove of the upper backing plate and the groove of the lower backing plate are arc-shaped grooves, and the curvature of the groove of the upper backing plate and the groove of the lower backing plate are the same. Steel balls 2 are placed between the upper backing plate groove and the lower backing plate groove, and the diameters of the steel balls between each upper backing plate groove and the lower backing plate groove are the same. Rubber posts 1 are set at the four corners of the upper backing plate and the lower backing plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com