Coke quality improvement synergist and its preparation and use method

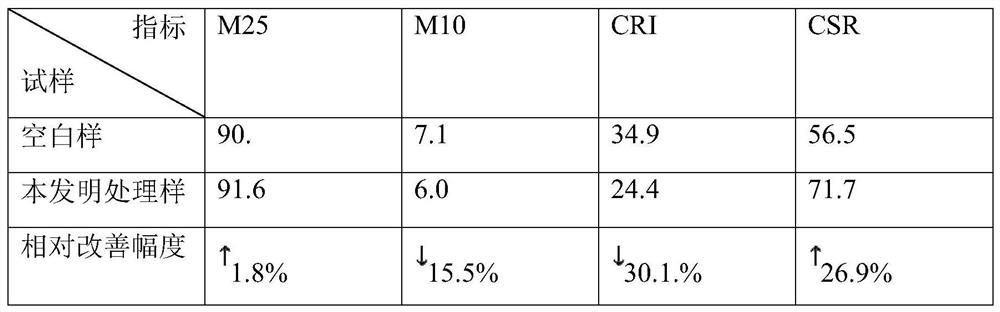

A quality-enhancing synergist and coke technology, which is applied in the new field of coking, can solve the problems of increasing coke ash content, high passivation agent price, and viscous solution, so as to improve fragmentation and wear resistance, reduce coal blending costs, The effect of increasing the thermal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of coke quality improving synergist (with 100kg as quantitative unit), its component and mass percent content are: succinic acid 0.1%, suberic acid 5.0%, N-acylglutamate (C 12 h 15 NO 6 S) 10.0%, cationic cellulose (cationic cellulose is a low irritation cationic polymer with excellent water solubility, conditioning, adsorption and repairing properties) 14.9%, titanium concentrate powder 10.0%, instant boron 10.0 %, boron trioxide 50.0%.

[0023] Prepare the coke quality-improving synergist according to the following steps: add the weighed components into a dry blender and mix evenly, the speed of the blender is controlled at 15 rpm, and the mixing time is controlled at 45 minutes. During the mixing process, the mixing tank is heated with electricity, and the temperature of the mixing tank is controlled at 100°C; the mixing material is dehumidified so that the moisture content of the quality-enhancing synergist is ≤1.0%. Then weigh and bag.

[0024] Dissolve ...

Embodiment 2

[0029] A preparation of a coke quality-improving synergist (with 100kg as the quantitative unit), its components and mass percent content are: 2.0% succinic acid, 3.0% suberic acid, 10.0% N-acyl glutamate, cationic Cellulose 8.0%, titanium concentrate powder 7.0%, instant boron 25.0%, boron trioxide 45.0%.

[0030] Prepare the coke quality-improving synergist according to the following steps: add various substances weighed into a dry blender and mix evenly, the speed of the blender is controlled at 20 rpm, and the mixing time is controlled at 40 minutes. During the mixing process, the mixing tank is heated with electricity, and the temperature of the mixing tank is controlled at 75° C., and the mixing material is dehumidified so that the moisture content of the quality-enhancing synergist is ≤1.0%. Then weigh and bag.

[0031] Dissolve the above-mentioned coke upgrading synergist with water into a solution with a mass concentration of 7.0%, spray the prepared solution three-d...

Embodiment 3

[0035] A preparation of a coke quality-improving synergist (with 100kg as the quantitative unit), its components and mass percent content are: 3.0% succinic acid, 0.1% suberic acid, 5.0% N-acyl glutamate, cationic Cellulose 6.9%, titanium concentrate powder 15.0%, instant boron 25.0%, boron trioxide 45.0%;

[0036] Prepare the coke quality-improving synergist according to the following steps: add various substances weighed into a dry blender and mix evenly, the speed of the blender is controlled at 30 rpm, and the mixing time is controlled at 30 minutes. During the mixing process, the mixing tank is heated with electricity, and the temperature of the mixing tank is controlled at 65° C., and the mixing material is dehumidified so that the moisture content of the quality-enhancing synergist is ≤1.0%. Then weigh and bag.

[0037] Dissolve the above-mentioned coke quality-improving synergist with water into a solution with a mass concentration of 1.0%, and spray the prepared solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com