Modified starch/polyamine compound, preparation method of modified starch/polyamine compound and application of modified starch/polyamine compound to stone processing waste water turbidity reduction

A compound and starch technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of product structure and branching degree that are not easy to control, not suitable for large-scale use, low molecular weight, etc., so as to improve the flocculation treatment capacity. , good removal effect, less dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Preparation of modified starch / polyamine compound

[0028] 1. Starch solid pretreatment:

[0029] The oven temperature was set at 200° C., and the starch solids were dried in the oven for 20 minutes.

[0030] 2. Hyperbranched polyamidoamine pretreatment:

[0031] The oven temperature was set to 200° C., and the hyperbranched polyamidoamine solid was dried in the oven for 15 minutes.

[0032] 3. Preparation of starch / polyamine compound:

[0033] 1) Put 10 g of dried starch solids into a beaker, add 15 mL of distilled water, and stir until completely dissolved to obtain a starch solution;

[0034] 2) Adjust the pH value of the starch solution to 7 with 0.5mol / L sodium hydroxide solution, and gelatinize at 95°C for 30min;

[0035] 3) Add 20 g of oxidant sodium hypochlorite to the product obtained in step 2) to oxidize for 50 min;

[0036] 4) Under the condition of a stirring speed of 100 r / min, 10 g of hyperbranched polyamidoamine was added, and the modif...

Embodiment 2

[0037] Example 2 Determination of the optimum conditions of the modified starch / polyamine compound during use

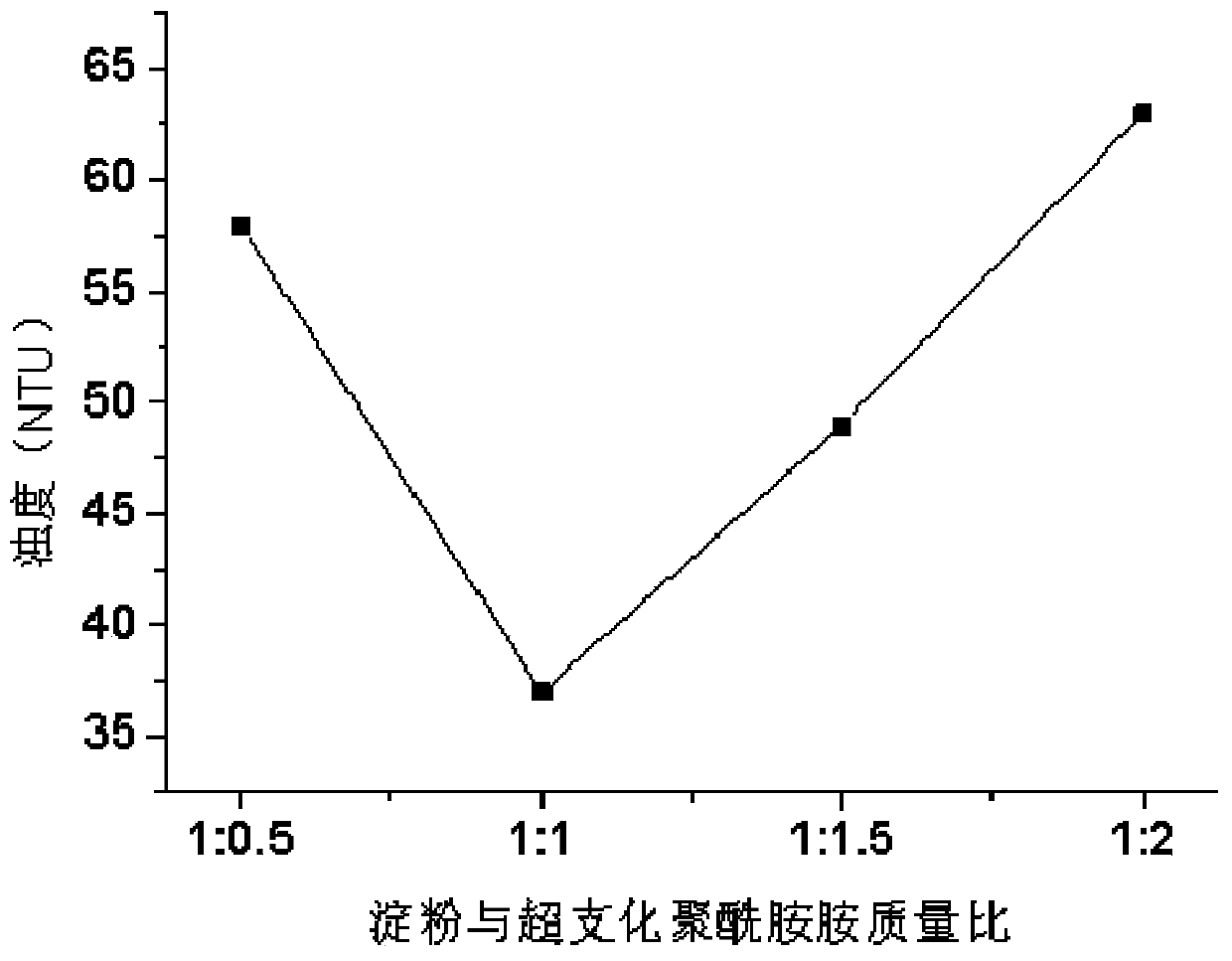

[0038] 1. Determine the ratio of starch and hyperbranched polyamidoamine

[0039] Dry starch solids and hyperbranched polyamidoamine solids respectively, according to the mass ratio, 1:0.5, 1:1, 1:1.5, 1:2, respectively take 4 parts of starch solids and 4 parts of hyperbranched polyamidoamine solids , the preparation method is the same as in Example 1, and a modified starch / polyamine compound is made.

[0040] Take 4 parts of 500mL stone processing wastewater and pour them into beakers respectively, add 4mg of the modified starch / polyamine compound prepared above, stir at 100r / min for 15min, flocculate and settle at room temperature for 2h, measure the turbidity of stone wastewater after treatment. Spend.

[0041] The result is as figure 1 As shown, as the mass ratio of starch to hyperbranched polyamidoamine increases, the turbidity first decreases and then increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com