System and method of three-stage type electro-Fenton for reducing wastewater chemical oxygen demand (COD)

A three-stage, wastewater technology, used in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc. problems, to achieve the effect of increasing secondary pollution, reducing blindness, and facilitating PID control

Inactive Publication Date: 2019-06-14

上海荣和环保科技有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] For this reason, the embodiment of the present invention provides a three-stage electric Fenton system and method for reducing COD of wastewater to solve the problem of complex wastewater COD treatment process, fuzzy ge

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

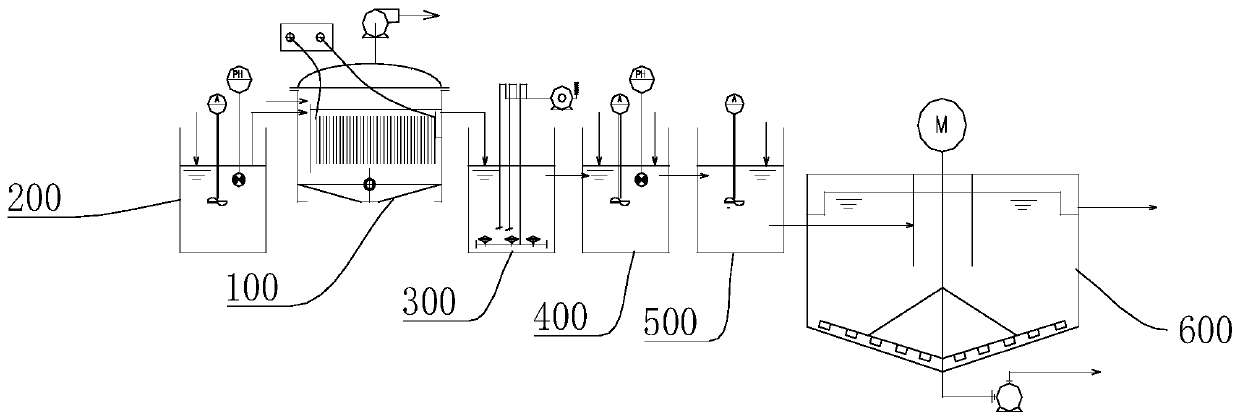

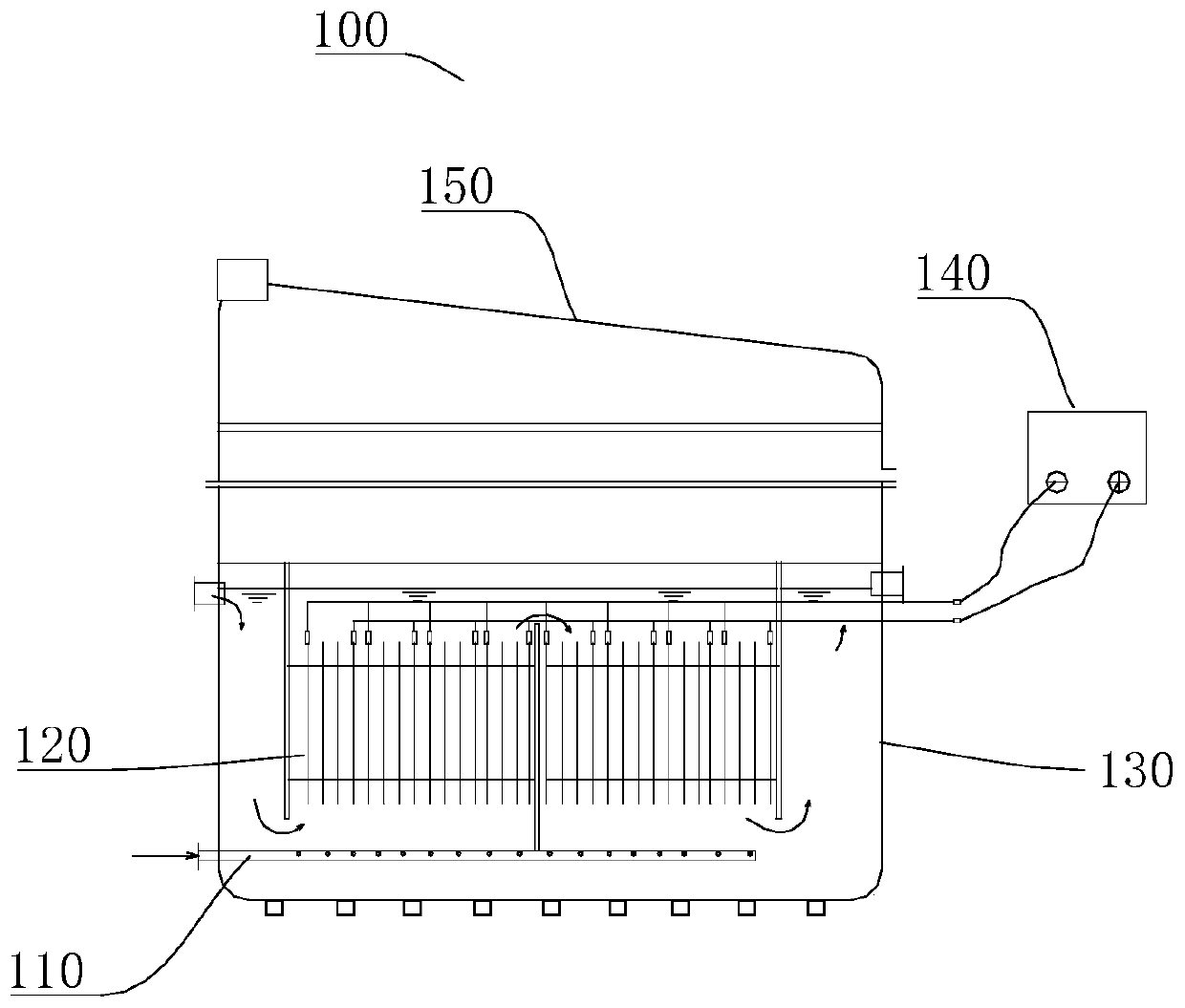

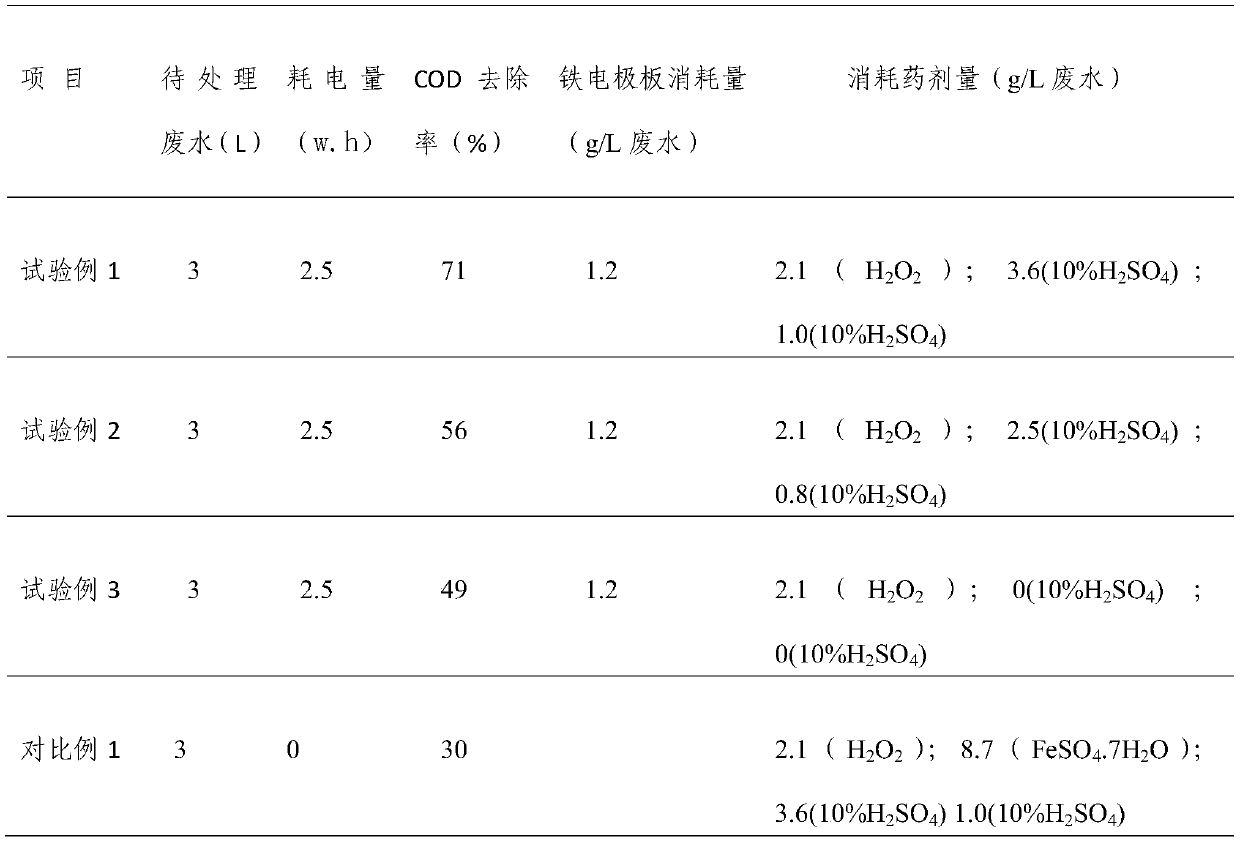

The embodiment of the invention discloses a system and method of three-stage type electro-Fenton for reducing wastewater chemical oxygen demand (COD). The method of the three-stage type electro-Fentonfor reducing the wastewater COD comprises the steps that in the first stage, wastewater added with quantitative H2O2 is introduced into an electrolytic bath with iron electrodes for electrifying, andelectrolysis is carried out for generating excess Fe<2+> and hydroxyl radical of organism in oxidized wastewater generated by reacting Fe<2+> with H2O2; in the second stage, excess H2O2 is removed through the Fe<2+> generated continuously by the iron electrodes; and in the third stage, air-blowing oxidation is carried out to oxidize the Fe<2+> to Fe<3+> for subsequent separation. According to themethod of the three-stage type electro-Fenton for reducing the wastewater COD provided by the embodiment of the invention, the capacity of oxidizing the organism is very strong, almost most organismsin current nature can be oxidized, the influence of excess H2O2 on a treated wastewater COD detection value is eliminated, and the COD of wastewater can be directly reduced to be below 50 mg/L or lower from 200-2000 mg/L; and compared with other advanced oxidation technology, a more accurate energy consumption material calculation result is achieved, a metal salt and a medicament residual in treated water are not added fundamentally, more stable effluent quality with higher quality is obtained, and the treatment method has the advantages of low cost and less occupied area.

Description

technical field [0001] The embodiment of the present invention relates to the technical field of wastewater treatment, in particular to a three-stage electro-fenton method for reducing COD of wastewater. Background technique [0002] At present, the methods for removing COD from wastewater are mainly biological methods and physical and chemical methods. With the improvement of wastewater discharge standards, the traditional COD removal method for some industrial wastewater can no longer meet the requirements of upgrading and transformation, such as the existing wastewater treatment method through anaerobic - aerobic - coagulation sedimentation - filtration - activated carbon adsorption After a series of processes, if you want to continue advanced treatment and further reduce the COD of wastewater, it is difficult to treat some industrial wastewater with traditional methods. Even if some methods can be done, the treatment cost is too high. [0003] In addition, some wastewat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F1/461C02F9/06C02F1/72

Inventor 乔春生何群彪陈兴权乔明晨殷礼文李涛颜锦华

Owner 上海荣和环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com