Automatic speed-cutting contact device for high-speed rail

A contact device, high-speed rail technology, applied in the direction of overhead lines, etc., can solve the problems of non-compulsory, achieve significant economic and social benefits, prevent tailing, derailment and rollover accidents, and avoid economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

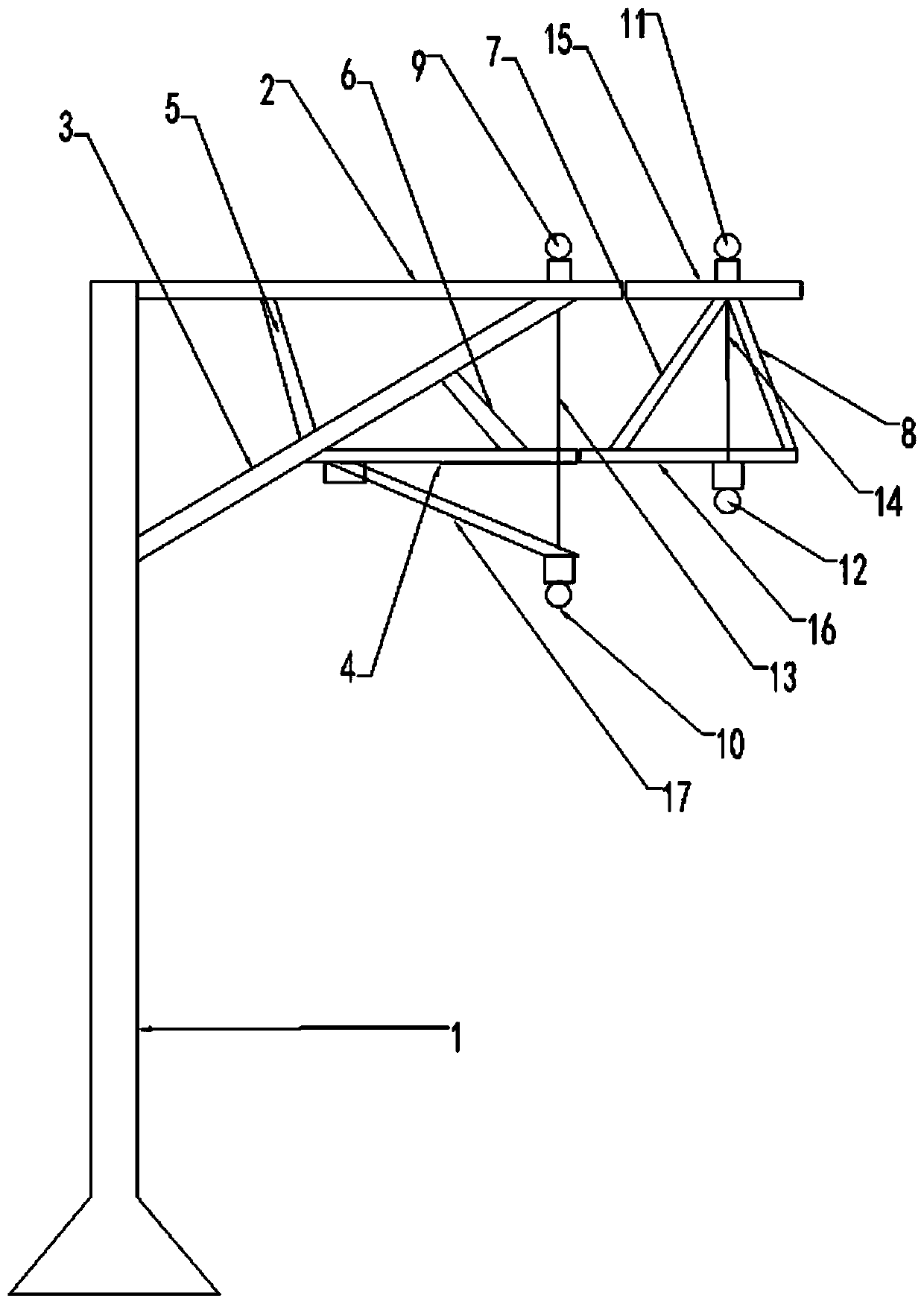

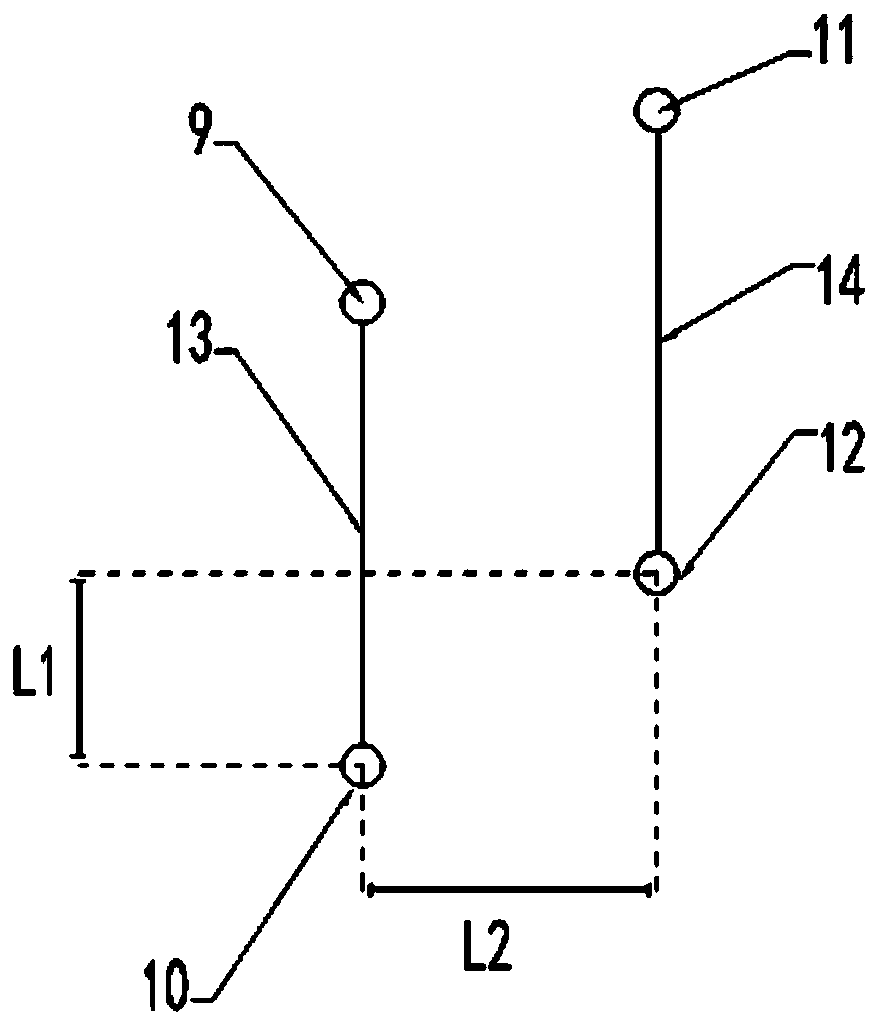

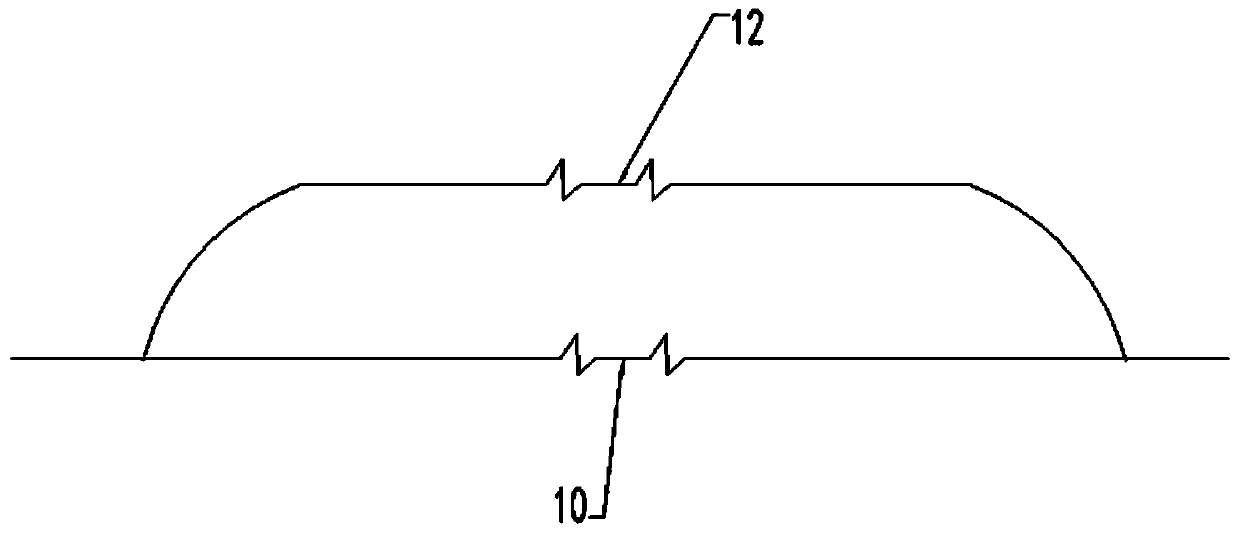

[0024] example, as Figure 1-3 As shown, an automatic deceleration type high-speed rail contact device includes a column 1, a contact wire 10 for power transmission for a high-speed train is suspended on the column 1, and a shunt wire 12 is connected in parallel on the contact wire 10 near the turn of the rail.

[0025] One side of the column 1 close to the upper end is connected to the contact line 10 and the shunt line 12 through a support device.

[0026] The support device includes a column top horizontal rod 2 fixedly connected on the top end side of the vertical column 1 , and the column top horizontal rod 2 is arranged laterally.

[0027] An inclined support rod 3 is fixedly connected between the column top horizontal rod 2 and the vertical column 1 , and a stable triangular structure is formed between the inclined support rod 3 , the column top horizontal rod 2 and the vertical column 1 .

[0028] A first oblique pull rod 5 is fixedly connected between the lower end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com