Pneumatic tire

A technology for pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, motorcycle tires, tire parts, etc., which can solve the problems of easy deterioration of rim fit and difficult bead fit, etc., to improve fit And the effect of steering stability performance, fit improvement, steering stability performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, one embodiment of the present invention will be described based on the drawings.

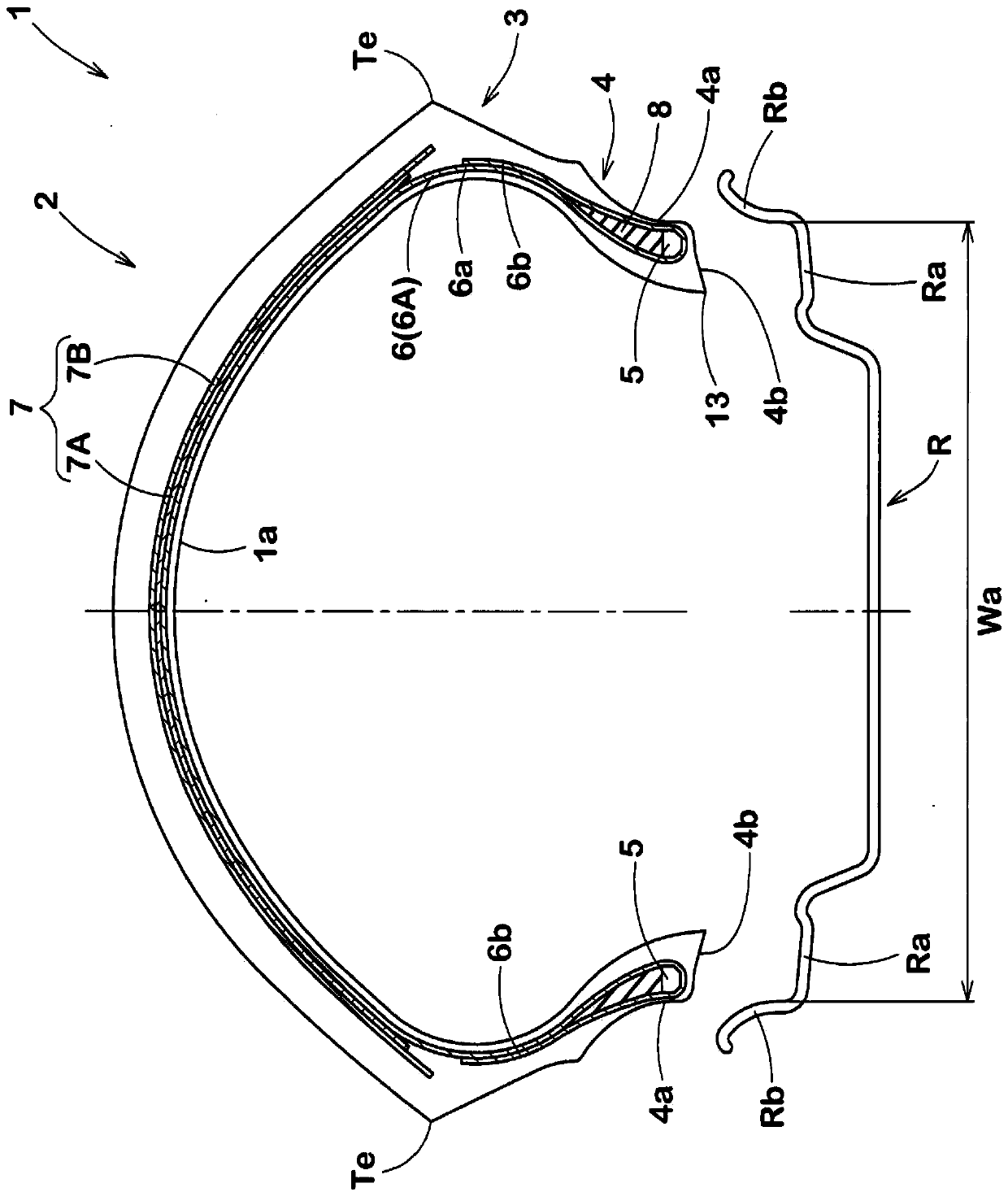

[0021] figure 1 It is a tire meridian cross-sectional view showing a tire rotation axis (not shown) in a pre-assembled state of a pneumatic tire (hereinafter, sometimes simply referred to as a "tire") 1 according to an embodiment of the present invention. In this embodiment, a motorcycle tire is shown as a preferable tire 1 . In addition, the tire 1 of the present invention is not limited to motorcycle tires.

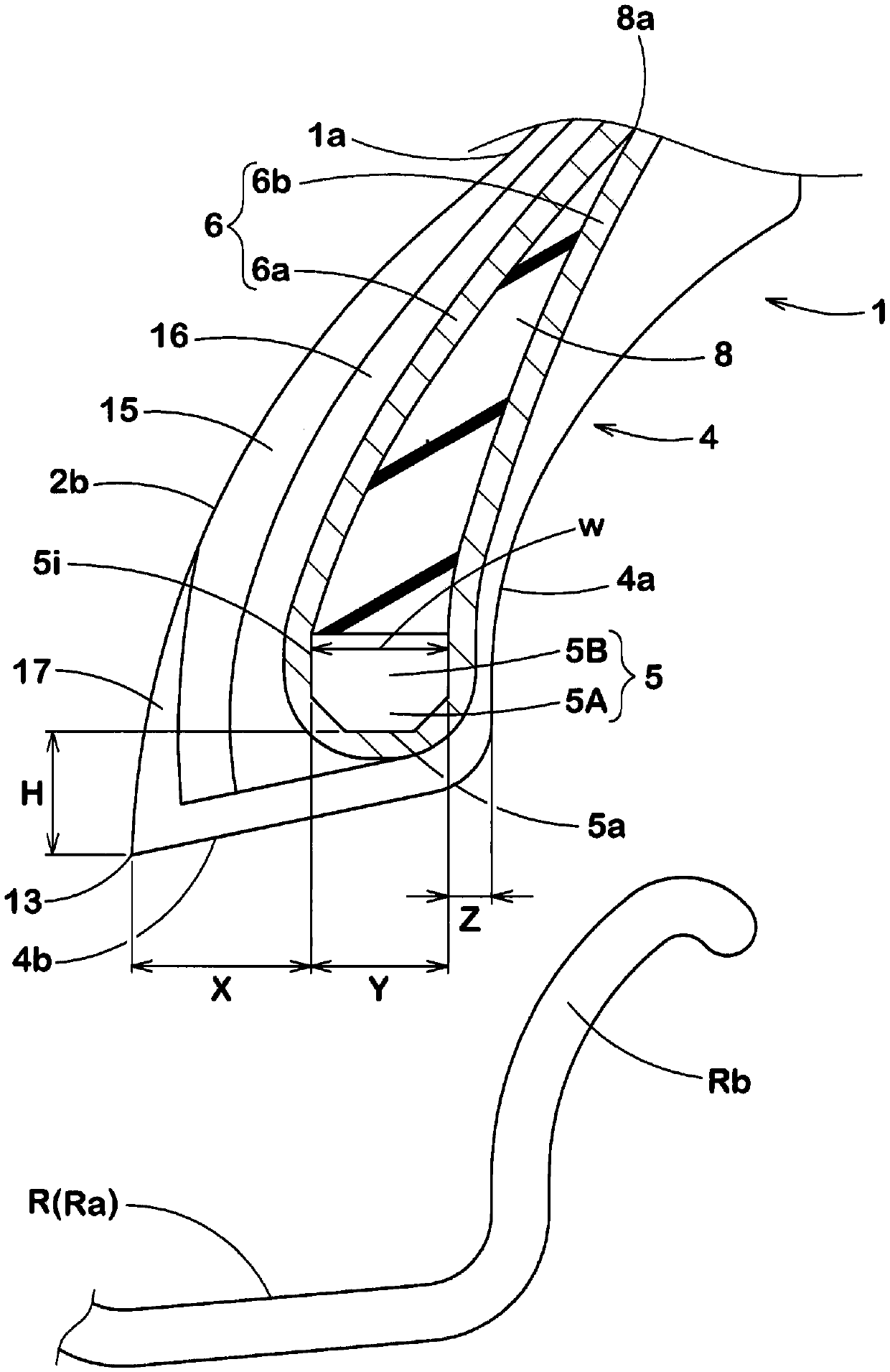

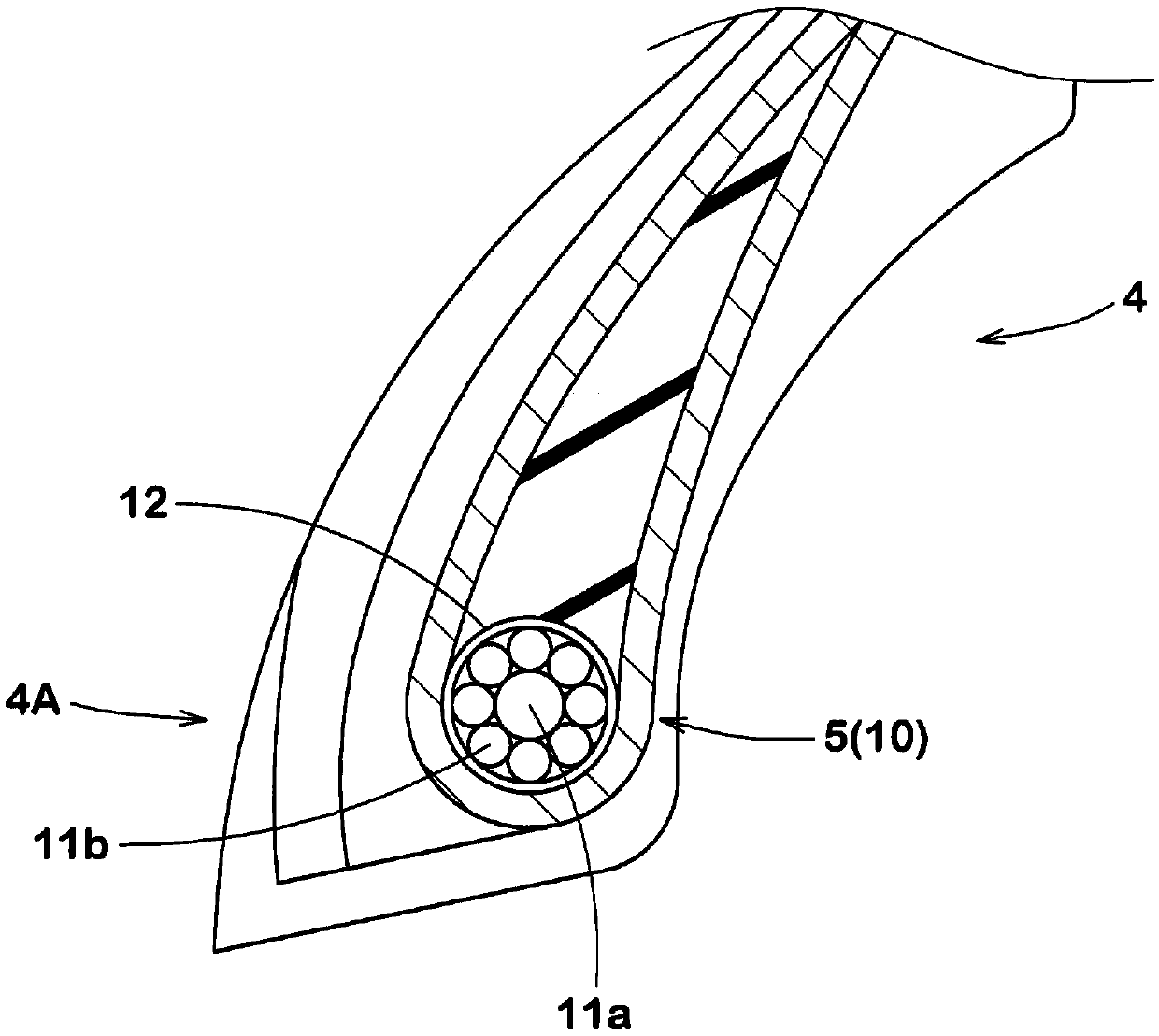

[0022] The tire 1 of the present embodiment has a carcass 6 extending from the tread portion 2 to the bead core 5 of the bead portion 4 via the sidewall portion 3 , and a belt layer 7 disposed outside the carcass 6 in the radial direction of the tire. .

[0023] The carcass 6 is formed of at least one layer (in this embodiment, one layer) of carcass ply 6A. The carcass ply 6A includes: a main body portion 6a annularly spanned between a pair of bead cores 5, 5; and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com