A preparation method of large-density anisotropic conductive metallized wood

A high-density, metallized technology, applied in wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of inconvenient operation, difficulty in ensuring uniform penetration, high risk, etc., to save the penetration process and maintain structure and strength , the effect of increasing the permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

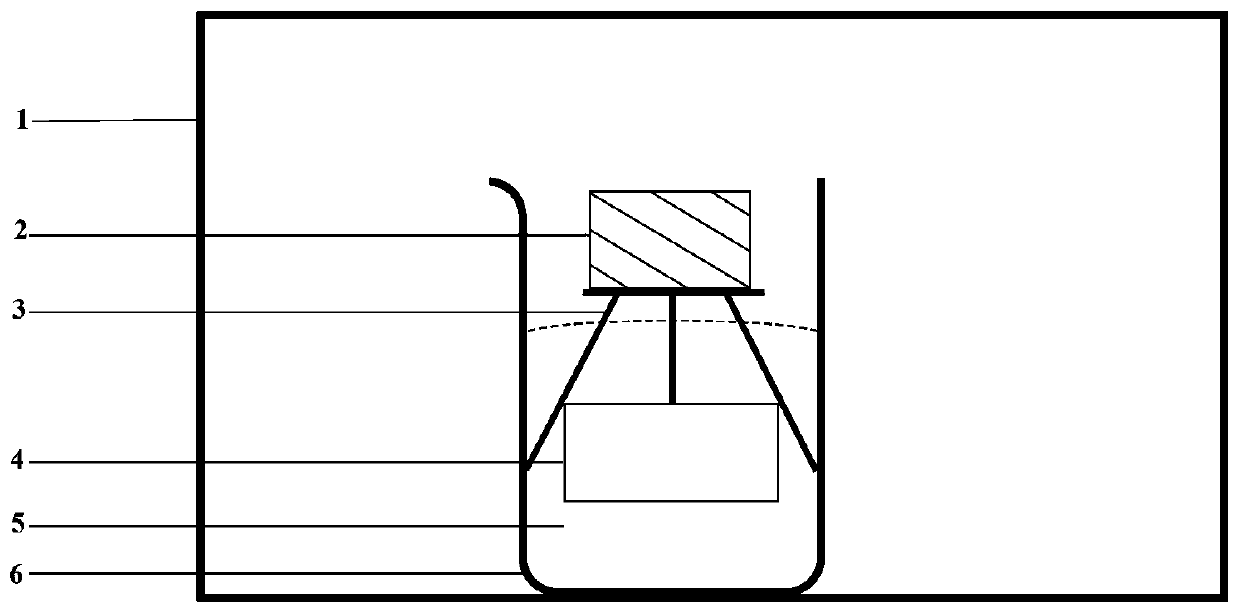

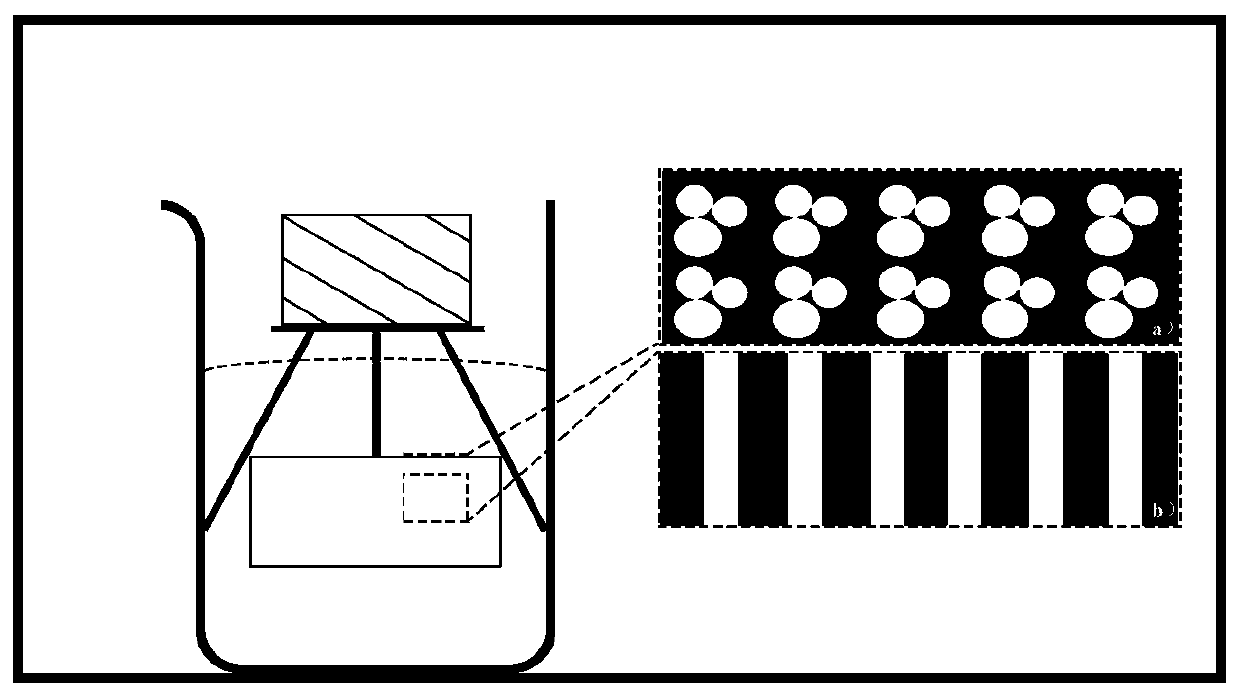

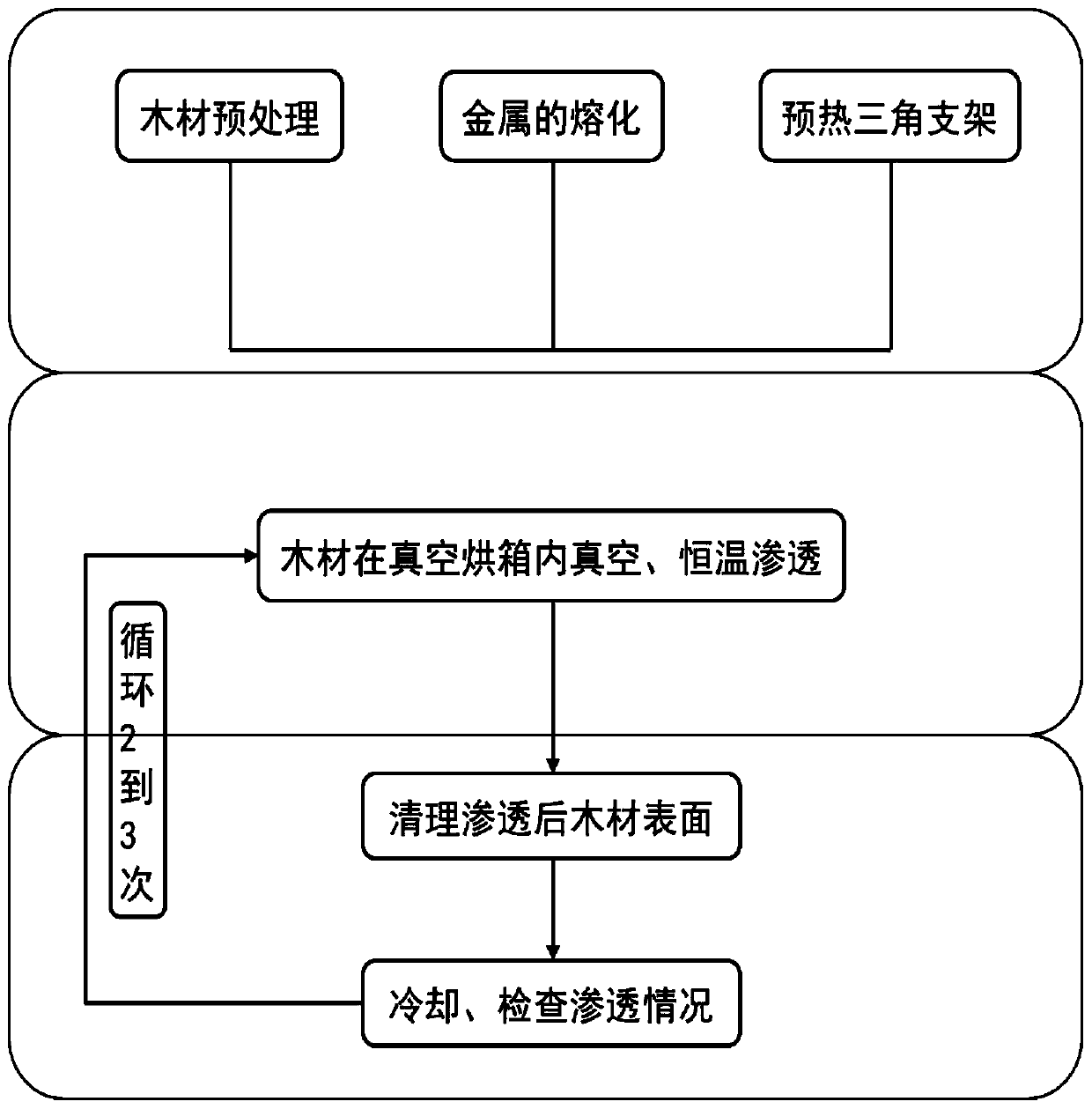

[0042] As shown in Figures 1 to 3, what the present embodiment prepared was basswood-tin-bismuth alloyed wood, and the preparation steps were as follows:

[0043] Step (1): The wood and metal used are basswood and tin-bismuth alloy with a melting point of 138° C. respectively. Cut basswood into a size of 35mm*35mm*5mm, put it in a beaker, add 40mL of dilute ammonia water with a mass fraction of 5%, cover the mouth of the beaker with plastic film to prevent volatilization, heat it to 80°C for five hours, and wash off the wood Lignin in the fiber structure. Take out the pretreated wood, put it into the oven, and press it on the upper surface of the wood with a flat steel block to prevent the wood from deforming during drying, then adjust the temperature of the oven to 100°C, bake for 2 hours, and take out the dried wood for use.

[0044] Step (2): Put the tin-bismuth alloy (tin 42%, bismuth 58%) in the beaker, adjust the temperature of the oven to 180° C., and wait for the meta...

Embodiment 2

[0051] What this embodiment needs to prepare is pine-tin-bismuth alloyed wood, and the preparation method adopted is basically the same as that of Example 1, except that:

[0052] The pine wood that adopts and the alloy that melting point is 180 ℃ of tin 62% bismuth 38% are raw materials. The melting point of the metal becomes higher, and the temperature of the vacuum oven needs to be kept at 220°C. In order to make the tin-bismuth alloy have better fluidity, the holding time needs to be increased to 1 hour. The obtained pine-tin-bismuth alloy metallized wood is shown in Figure 3.

[0053] The change in density is obtained as follows:

[0054] Timber specification 35mm*35mm*5mm, melting point: 180°C

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com