Novel segmented stator core turnplate welding machine

A stator core and block technology, which is used in the manufacture of stator/rotor bodies, welding equipment, auxiliary devices, etc., can solve the problems of low production efficiency, different soldering levels of pins, and low quality of insulator cores, and achieves safety. The effect of improving and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

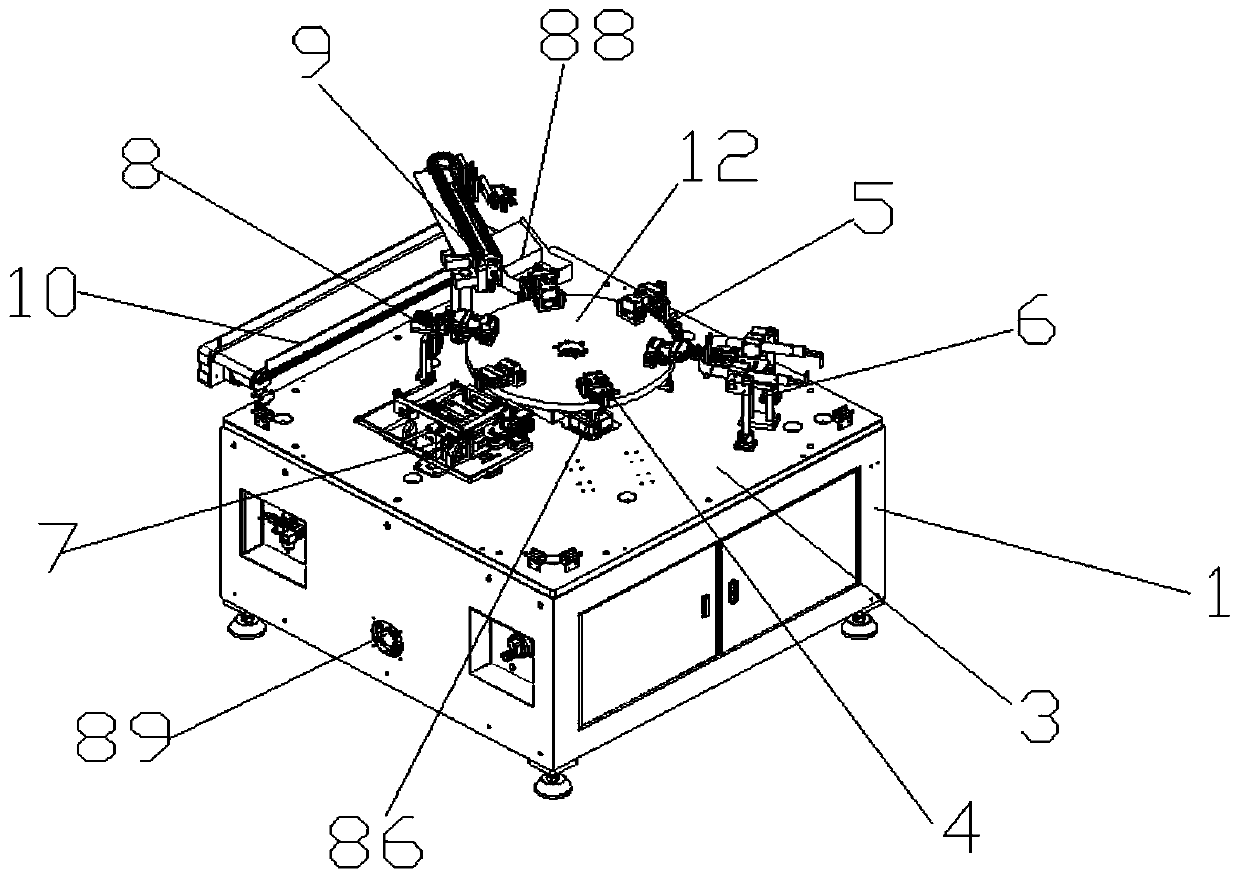

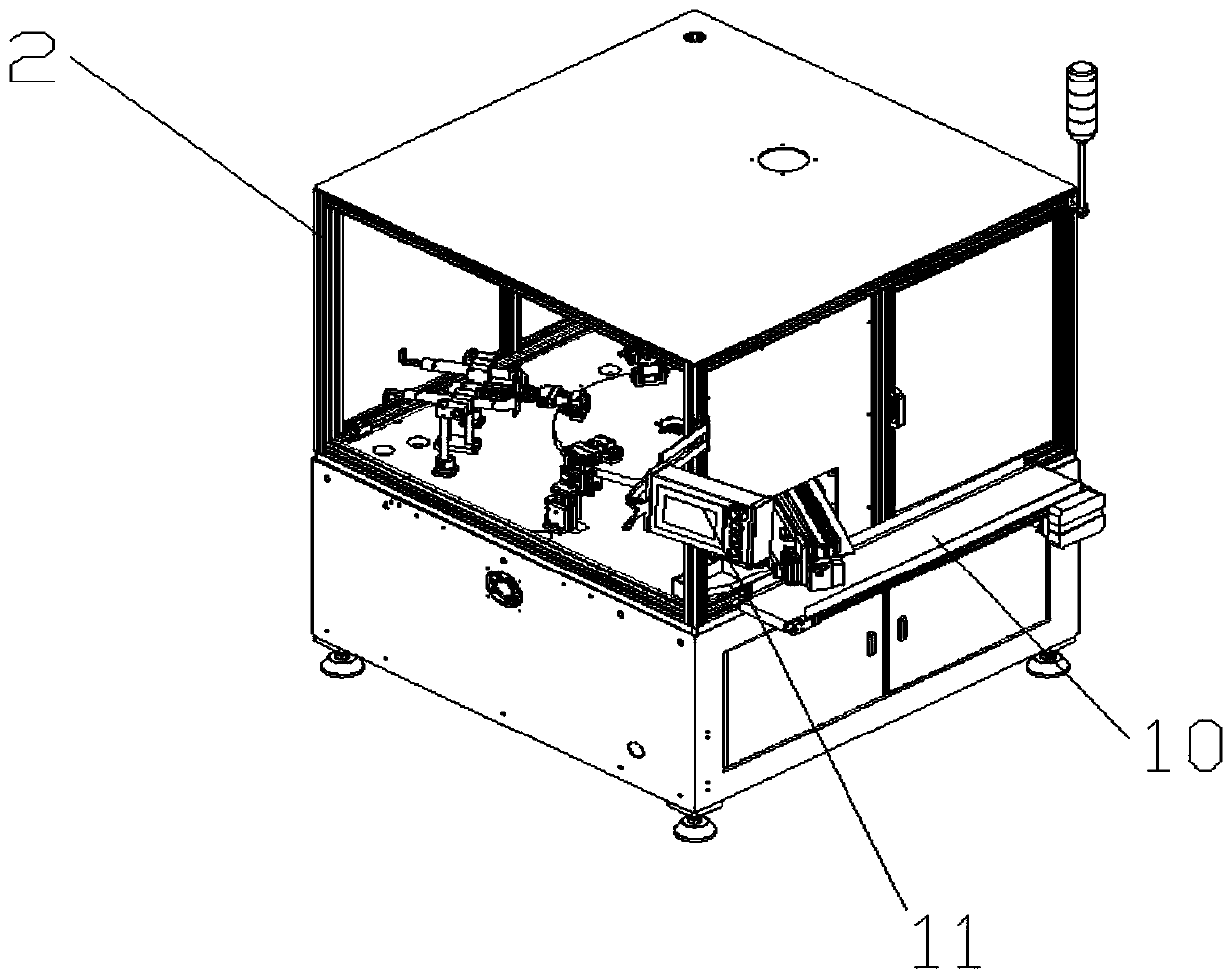

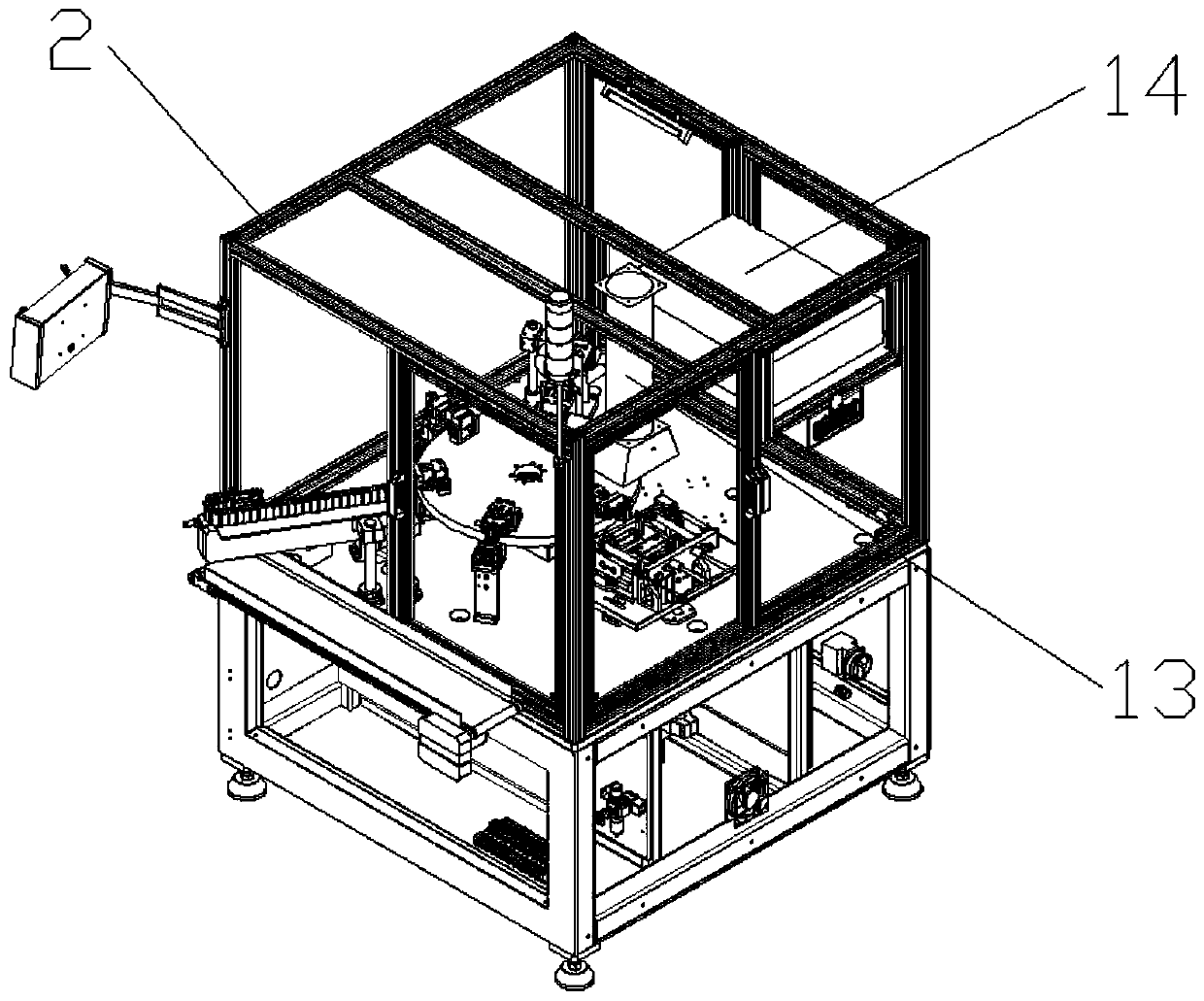

[0051] refer to Figure 1 to Figure 14A new block-type stator core turntable welding machine is shown, including a chassis 1, a protective cover 2, a workbench 3, a fixed tool 4, a feeding device 5, a shaping device 6, a soldering device 7, a testing device 8, a lower Material device 9, comprehensive detector 14, iron core 21 and manipulator 84, workbench 3 is installed between cabinet 1 and protective cover 2, and the upper end of workbench 3 is provided with a turntable 12, and the lower end of turntable 12 is connected with motor two 86 , the motor two 86 drives the turntable 12 to rotate, the fixed tool 4 is installed on the turntable 12, the fixed tool 4 is provided with a plurality of, the iron core 21 is fixed on the fixed tool 4, and the iron core 21 includes a copper wire 15, a plastic shell 16. Outer insulating paper 17, inner insulating paper 18, metal skeleton 19 and pins 20, the feeding device 5, shaping device 6, soldering device 7, testing device 8 and unloading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com