Overturn type pneumatic control cooling system for granule structure feed production

A particle structure, flip technology, applied in feed, application, food science and other directions to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

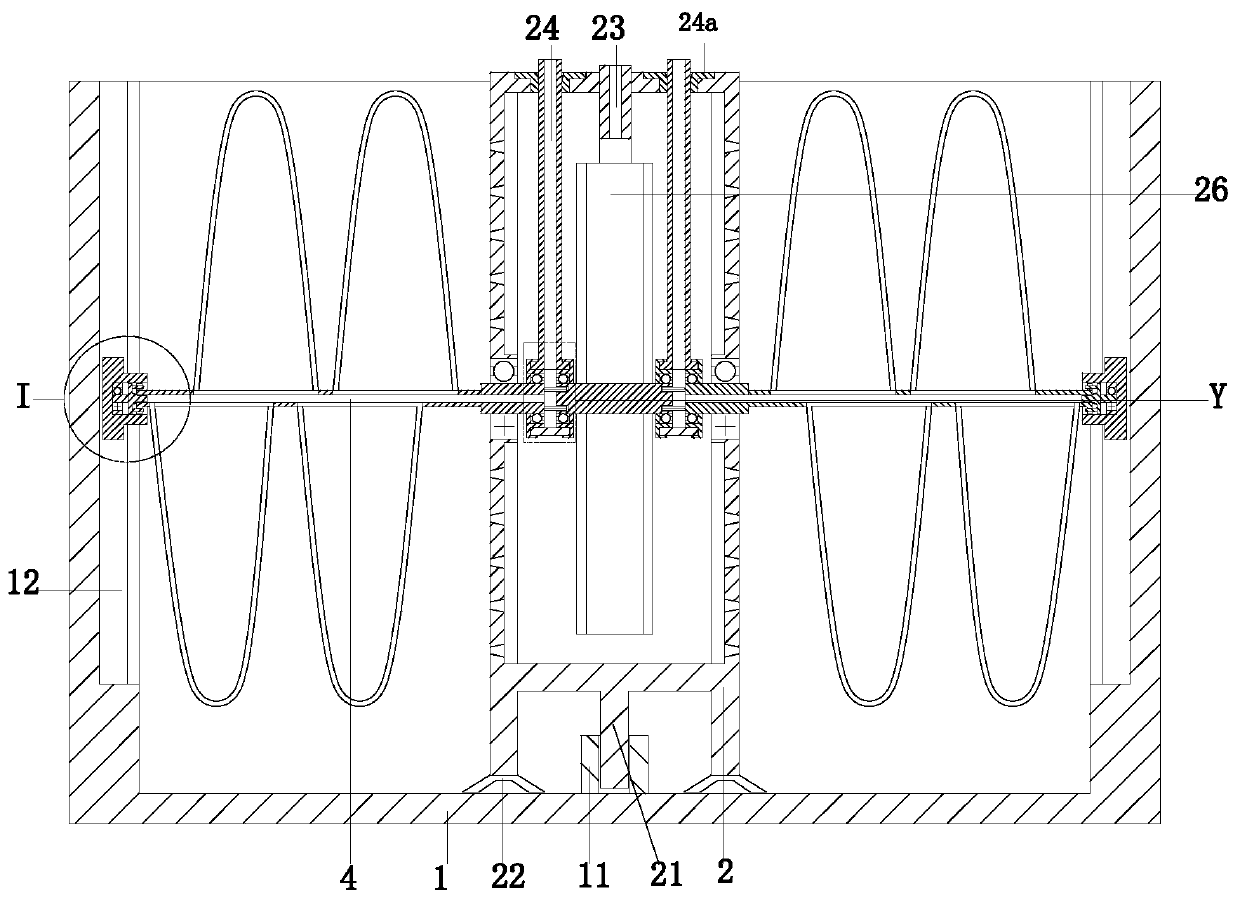

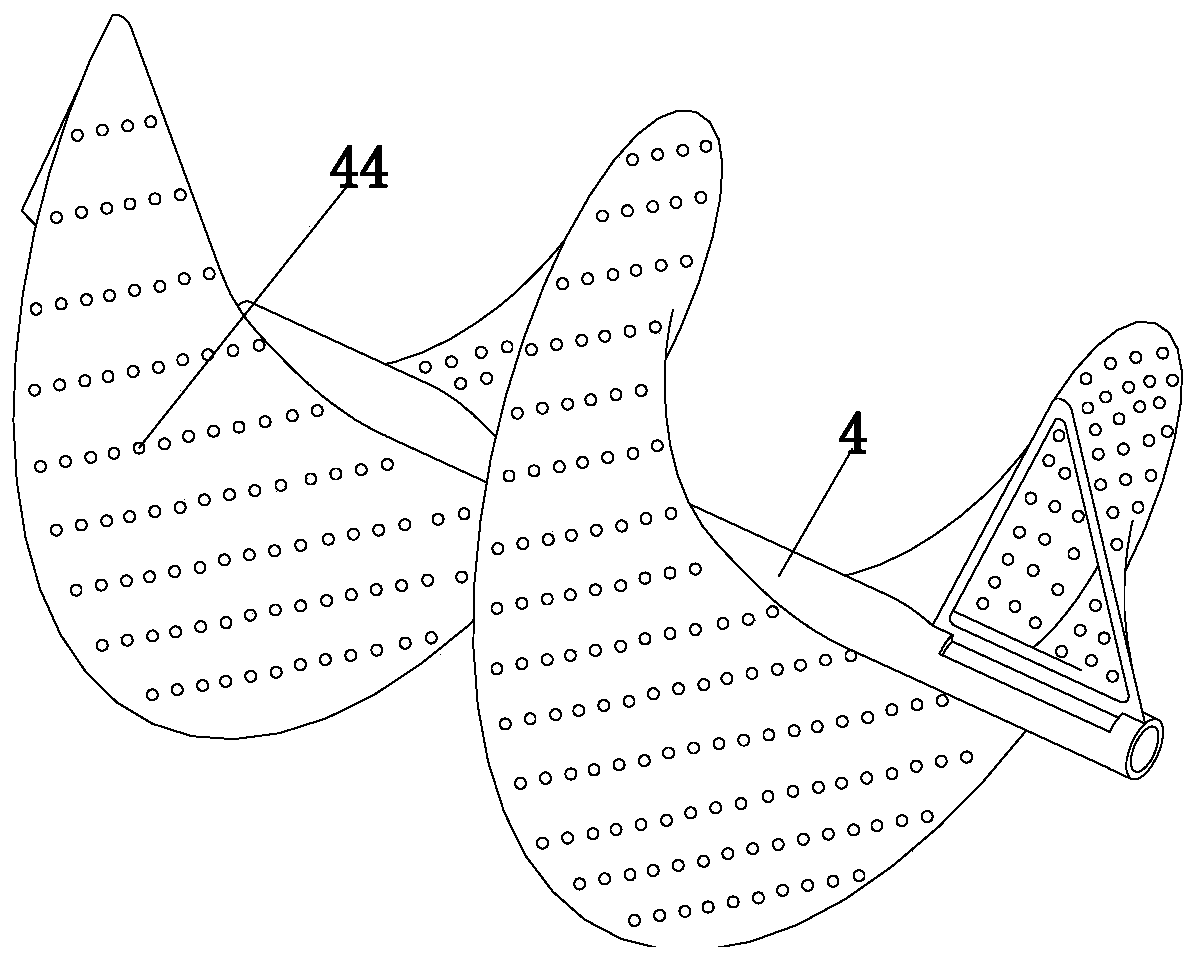

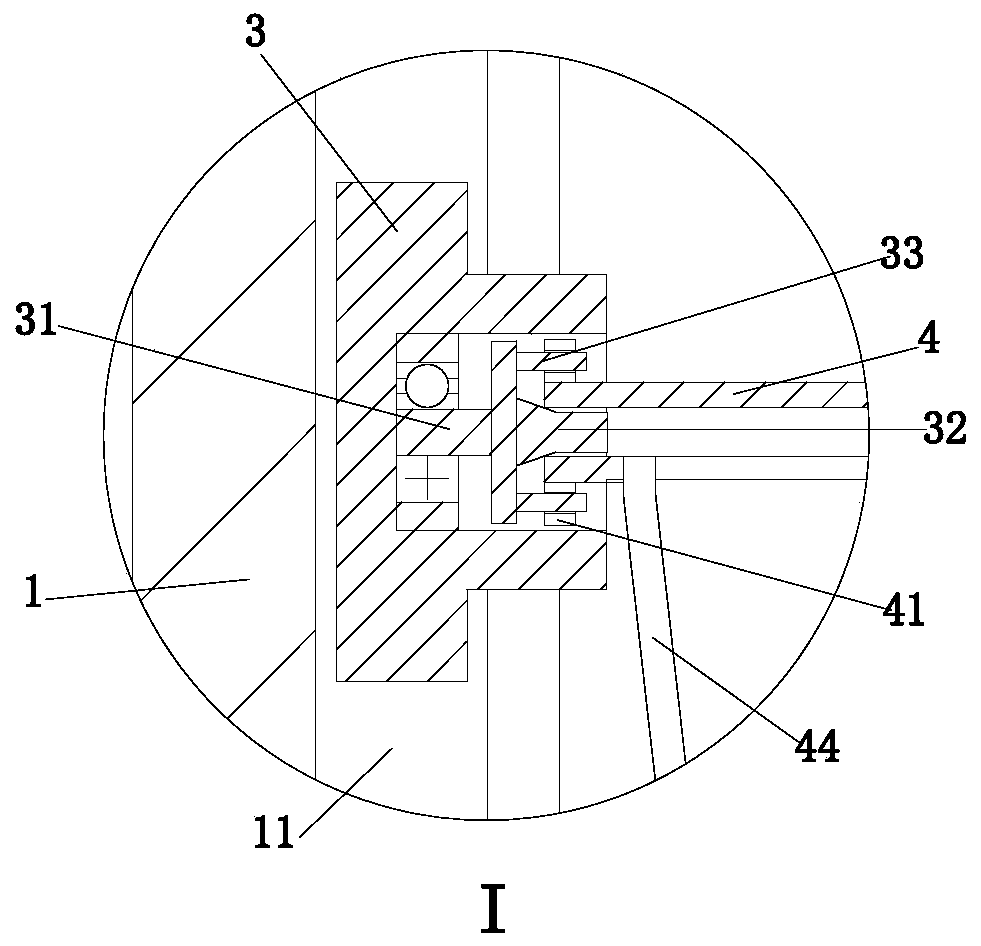

[0032] Such as Figure 1 to Figure 6 As shown, the flip-type wind control cooling system for the production of granular structure feed includes a placement frame 1, and a cooling frame 2 is detachably arranged in the placement frame 1.

[0033] The inner wall of the lower end of the placement frame 1 is provided with clamping slots 11, and the inner walls of the left and right ends of the placement frame 1 are symmetrically provided with locking slots 12, and the locking slots 12 have a T-shaped structure.

[0034] The lower end of the cooling frame 2 is provided with a clamping block 21 , and the left and right sides of the lower end of the cooling frame 2 are symmetrically provided with suction strips 22 . The width of the section of the suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com