Threshing device with adjustable two-way drawing wire threshing interval and combined harvester

A technology of threshing device and radial pull wire, which is applied in the direction of harvesters, threshing equipment, agricultural machinery and implements, etc. It can solve the problems of difficult adjustment of threshing gap and low degree of automation, and achieve convenient and quick operation, solve instability, and prevent drum The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The working process of embodiment 1:

[0045] When the combine harvester starts to work, the material is fed into the threshing device through the conveying trough, and collides and rubs against the concave screen under the high-speed impact on the threshing drum to achieve threshing. When the combine harvester was working as normal, the upper part 401 of the radial backguy and the tangential backguy 8 were all in a tensioned state, and the grid bar was clamped, as Figure 9 As shown in the figure, under the positions of the grid bar 1 and the threshing cylinder 12, the threshing gap is L 1 ; but in the actual operation process, the feeding amount will fluctuate with the distribution density of the field crops. When the feeding amount is too large or fluctuates, it will directly cause the load of the threshing drum 12 to change, and in severe cases, it will cause the threshing drum 12 Blockage and stop. When it is detected that a blockage is about to occur, the upper s...

Embodiment 2

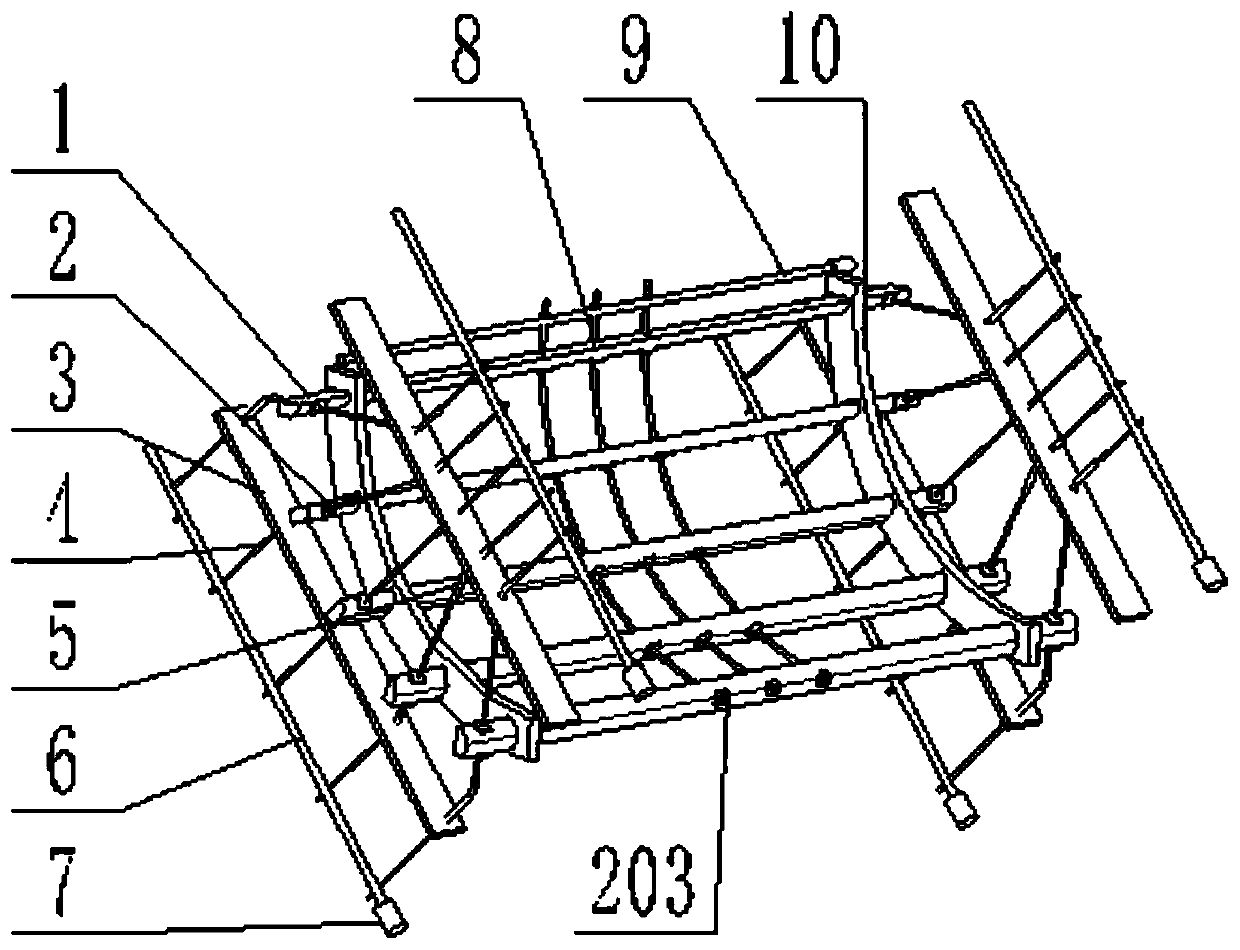

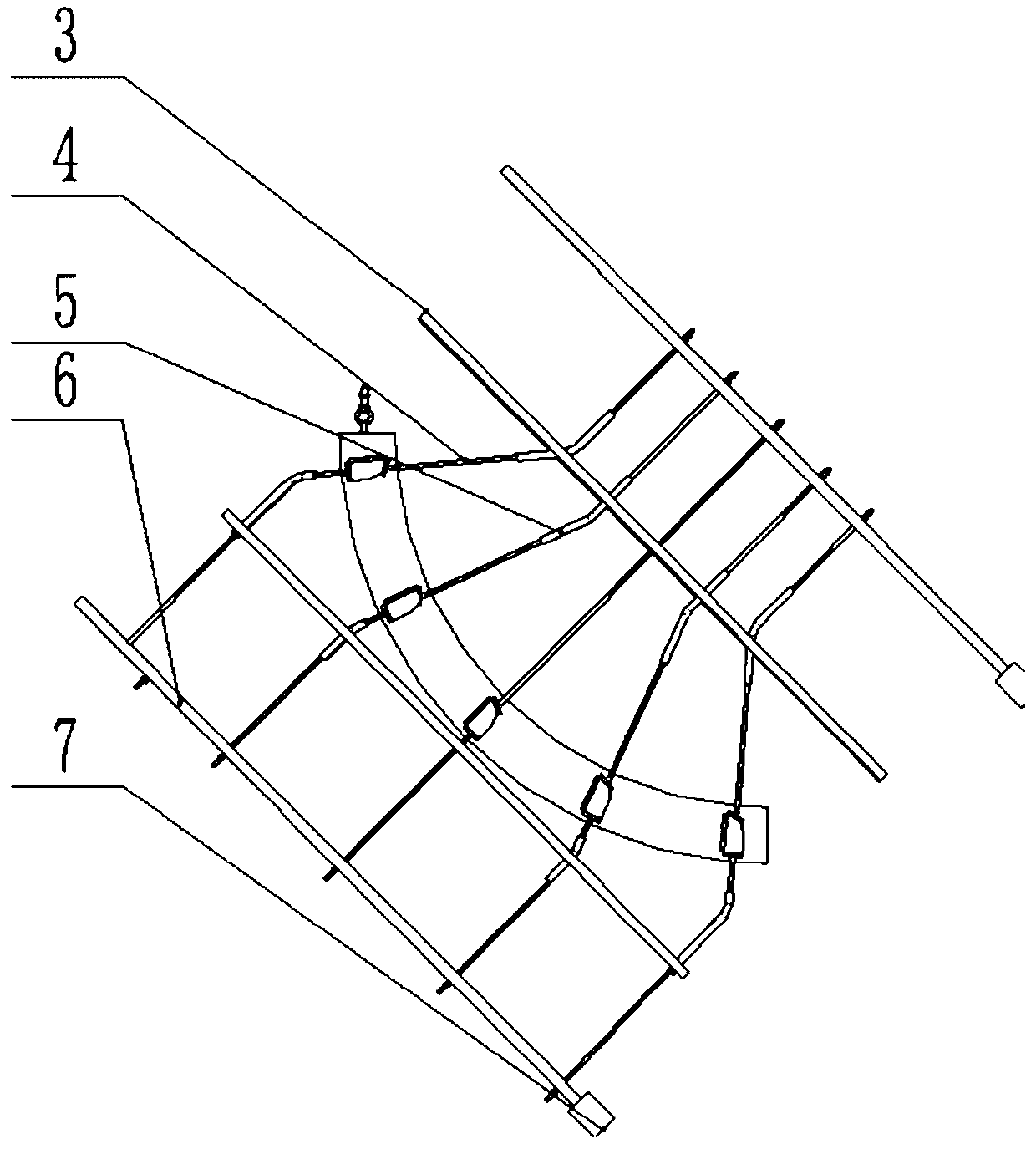

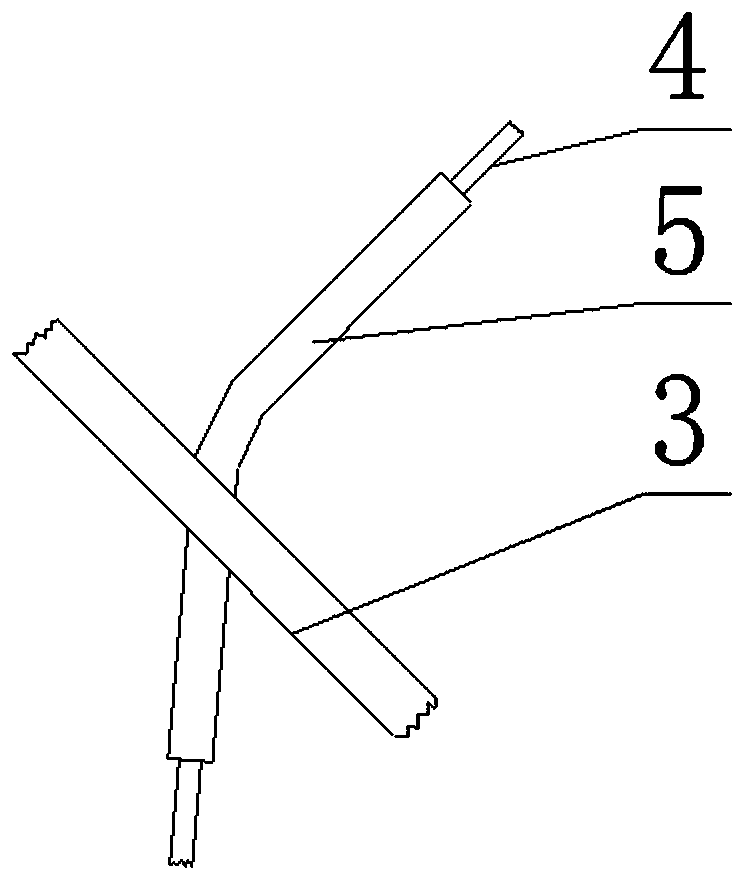

[0046] Example 2 as Figure 4 , Figure 5 and Figure 7 As shown, the threshing device with adjustable two-way pull wire threshing gap according to the present invention includes a tension mechanism, which includes an elastic gasket 2, a guide pulley 3', a radial pull wire 4, a chute 5', and an A pull rod 6' , electric push rod 7', tangential stay wire 8 and B pull rod 9'. The grid bar 1 is installed in the hole of the side plate 10, and the grid bar 1 has a certain gap in the radial and tangential directions, which is convenient for the grid bar 1 to move in the radial direction, and then adjust the threshing gap. There are holes along the radial direction on both sides of each grid bar, and several tangential holes are equally spaced in the middle. On both sides of the concave plate, the radial direction of the grid bar 1 is respectively arranged with the A upper rod 601' and the A lower rod 602', and one end of the radial pull wire 4 passes through the radial hole of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com