Intelligent lawn mower and application method

A lawn mower and intelligent technology, applied in the field of herb trimming under high-speed guardrails, can solve the problems of low degree of automation, waste of human resources, low efficiency, etc., and achieve the effect of efficient trimming of herbs and efficient trimming of herbs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

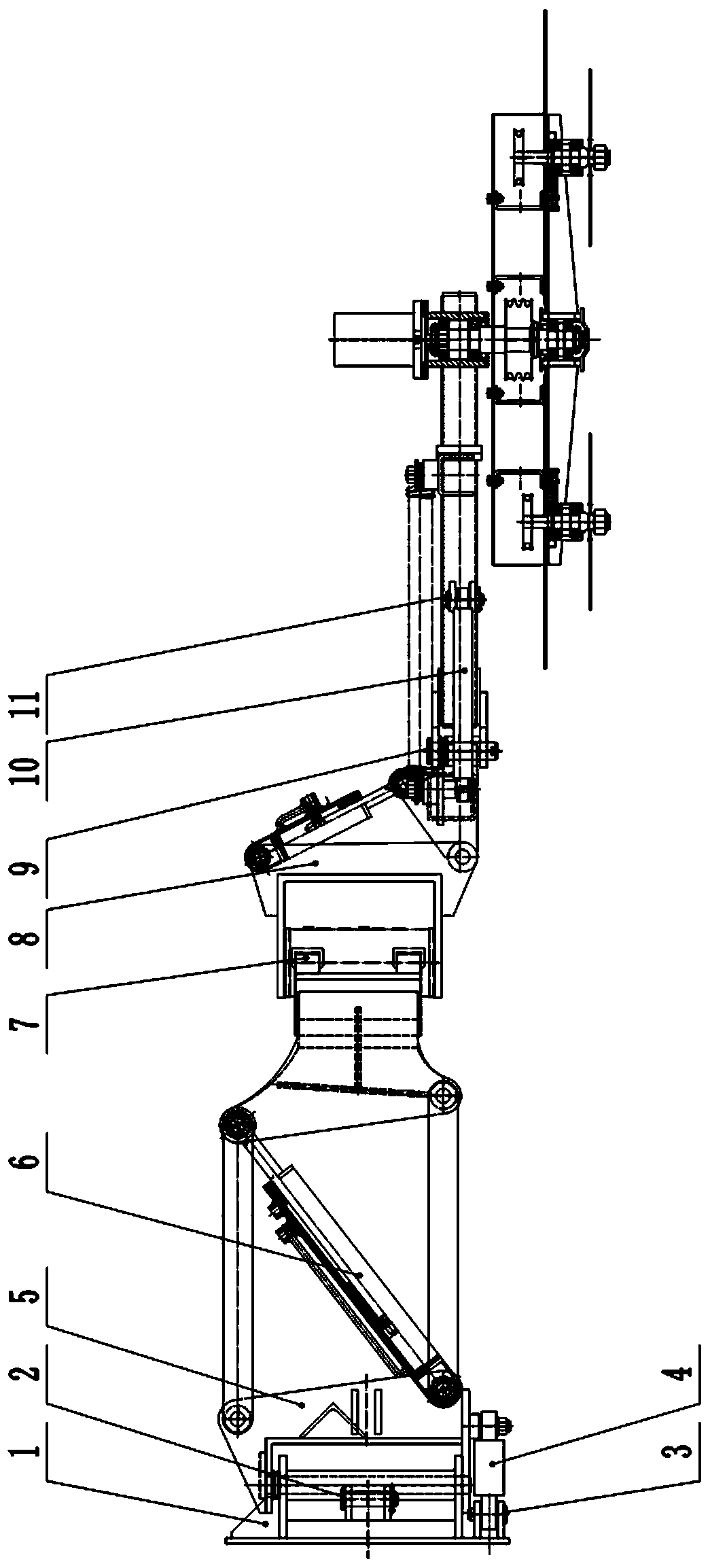

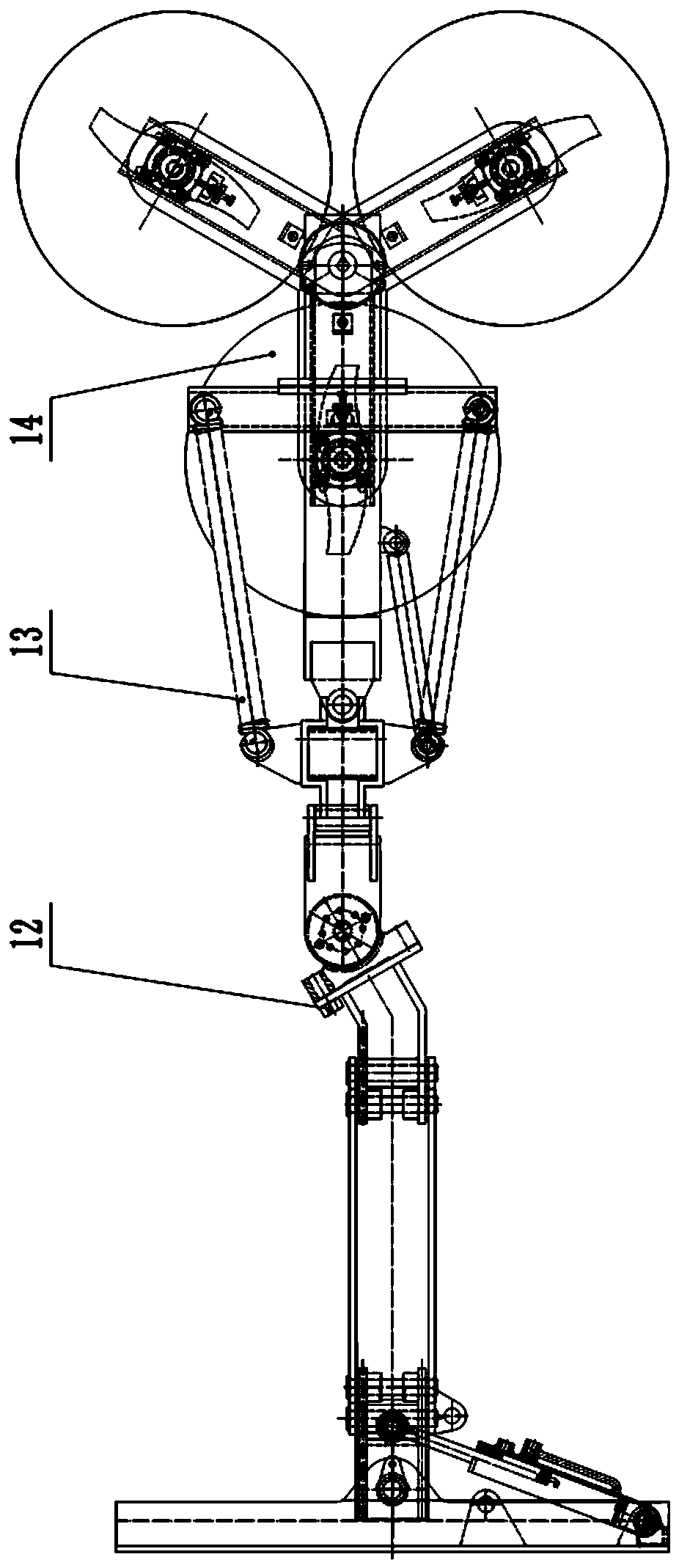

Embodiment 1

[0024] Embodiment 1. This device includes vehicle connecting frame 1, fixed pin shaft 2, first pin shaft 3 of left and right oil cylinders, left and right oil cylinders 4, lifting device 5, lifting oil cylinder 6, swing oil cylinder 7, cutterhead leveling device 8, connecting pin Axle 9, cutter head fixed rod 10, first pin shaft 11 of fixed rod, swing oil cylinder fixing bolt 12, balance extension spring 13, cutter head device 14. The vehicle connecting frame 1 is installed on the front end of the vehicle; the lifting device 5 is installed on the vehicle connecting frame 1 through the vehicle connecting frame and the lifting device connection pin 23; On the first pin shaft 3 of the left and right oil cylinders on the top, the other end is installed on the second pin shaft 19 of the left and right oil cylinders on the lifting device 5, which can control the lifting device 5 to take the vehicle connecting frame and the connecting pin 23 of the lifting device as the center. Rotat...

Embodiment 2

[0025] Embodiment 2. The vehicle connecting frame 1 includes the left and right oil cylinder lugs 15, the vehicle connecting frame frame 16, the first fixed pin lug 17, the left and right oil cylinder lugs 15 and the fixed pin first lugs 17 are welded on the vehicle connection on frame 16.

Embodiment 3

[0026] Embodiment 3, the lifting device 5 includes a four-link rear frame 18, a second pin shaft 19 of the left and right oil cylinders, a second ear plate 20 of a fixed pin shaft, a four-bar link 21, a four-link front frame 22, a vehicle connecting frame and Lifting device connection pin 23, four-link pin 24, wherein, four-link rear frame 18, four-link front frame 22, two four-link 21 are assembled into a parallel by four four-link pins 24 Quadrilateral four-bar linkage assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com