Leak-proof evaporator valve

An evaporator and anti-leakage technology, which is applied in the direction of diaphragm valves, valve devices, engine components, etc., can solve the problems of affecting the normal use of evaporators, evaporator leakage, and the decrease of tightness of closing, so as to achieve ingenious design and long service life. Long, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

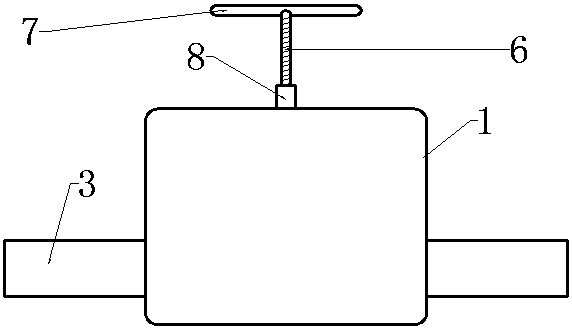

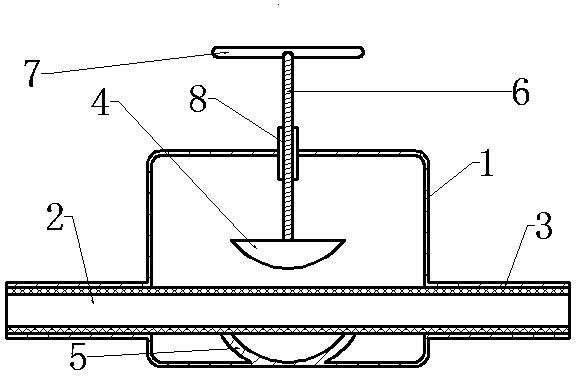

[0016] The evaporator valve includes a rectangular box-shaped shell 1, and round tube-shaped support tubes 3 are vertically arranged on both sides of the shell 1, and a round tube-shaped flexible tube 2 is fixed inside the two support tubes 3 and the shell 1. 1. The top is vertically inlaid with a round pipe-shaped threaded pipe 8. The threaded pipe 8 is tapped with concave threads. The threaded pipe 8 is equipped with a threaded rod 6 that is threaded with each other. The threaded rod 6 is located on the outer end of the shell 1. One end of the threaded rod 6 located inside the housing 1 is vertically provided with a pressing plate 4, and the pressing plate 4 protrudes in a quarter-circle arc shape toward the side of the flexible pipe 2, and a quarter-circle is provided at the center of the bottom of the inner wall of the housing 1. A round arc-shaped locking sleeve 5, the concave surface of the locking sleeve 5 faces the flexible pipe 2, the concave surface of the locking sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com