Wind-resistant locking device for final closure of steel truss beams erected by hole and application method thereof

A locking device, a technology of steel truss, applied in the erection/assembly of bridges, truss bridges, bridge construction, etc., can solve the problems of weak wind resistance, poor stability, damage to steel truss girder down the river wharf and large floating cranes, etc. To achieve the effect of simple structure, safe and efficient method, convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

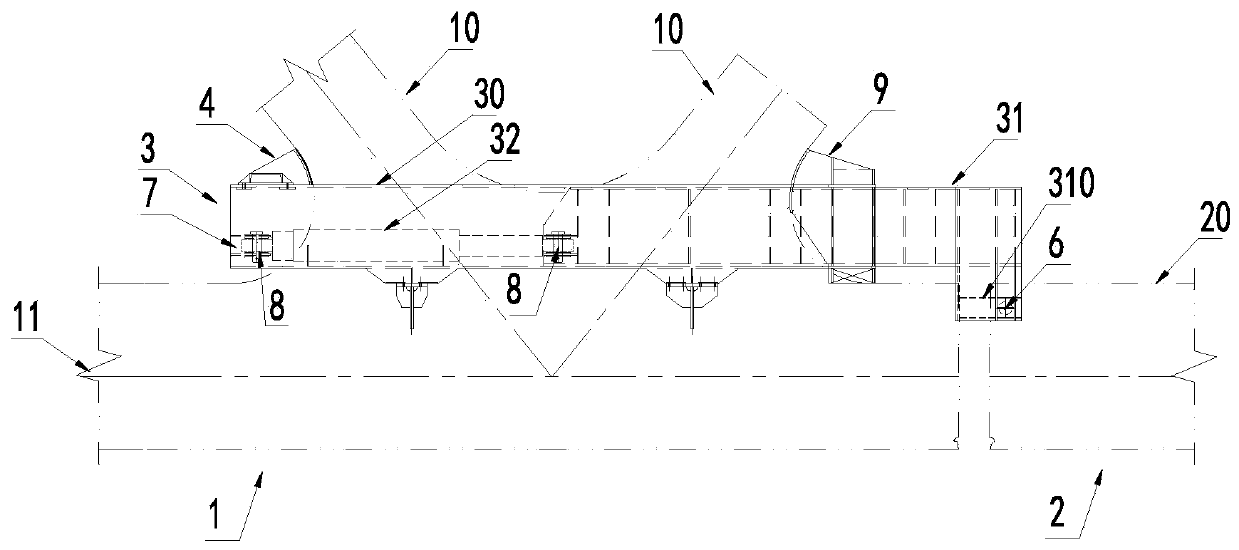

[0035] see figure 1 with figure 2 As shown, the embodiment of the present invention provides a wind-resistant locking device for erecting a steel truss girder hole by hole, which is used to temporarily lock the erected A-span steel truss girder 1 and the B-span steel truss girder 2 to be erected , the wind-resistant locking device includes two telescopic arms 3, a rear beam 4 and two push mechanisms 6;

[0036] combine figure 1 with figure 2 As shown, two telescopic arms 3 are respectively arranged on both sides of the oblique rod 10 of the A-span steel truss girder 1 along the transverse bridge direction, and the telescopic arms 3 include an outer sleeve 30 , an inner sleeve 31 and a driving mechanism 32 .

[0037] The outer sleeve 30 in this embodiment is U-shaped, and the U-shaped single limb is a box-shaped structure, which is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com