Cone-shaped screw

A tapered screw, tapered rod technology, applied to the tapered screw. It can solve the problems of high cost, slow rising speed of extrusion force, unsatisfactory material processing effect, etc., and achieve the effect of accelerating deformation and flow, improving efficiency and increasing the number of mixing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

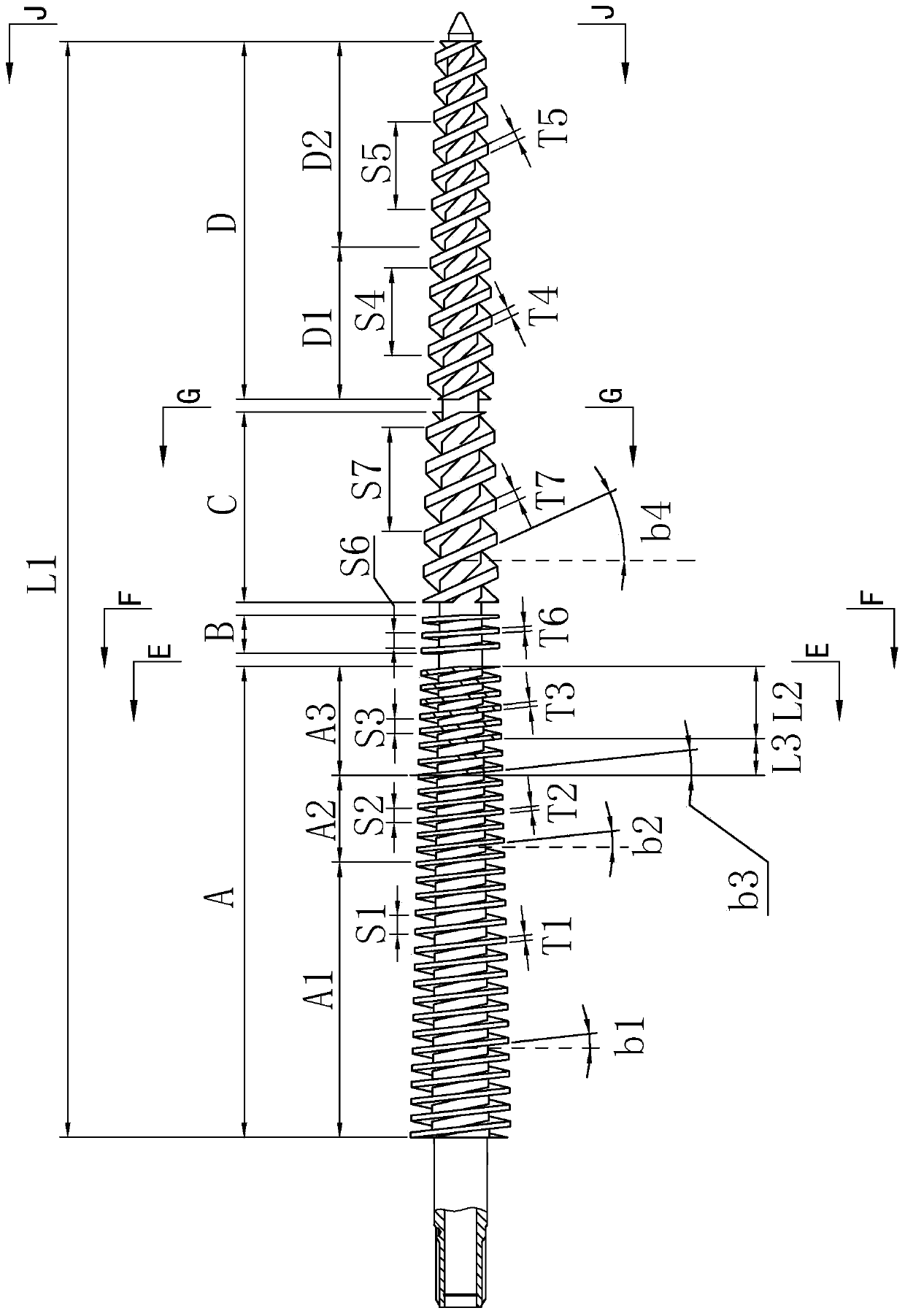

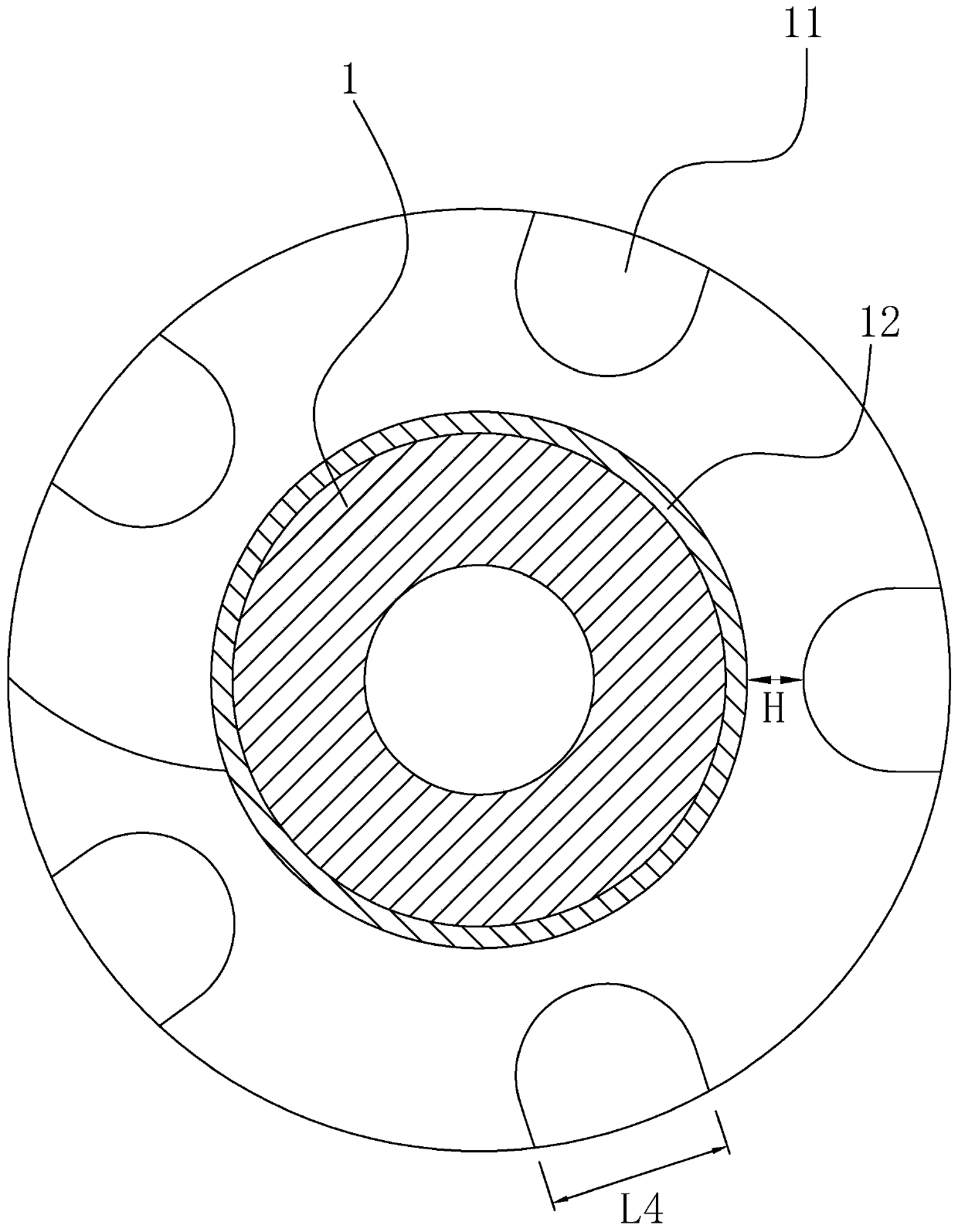

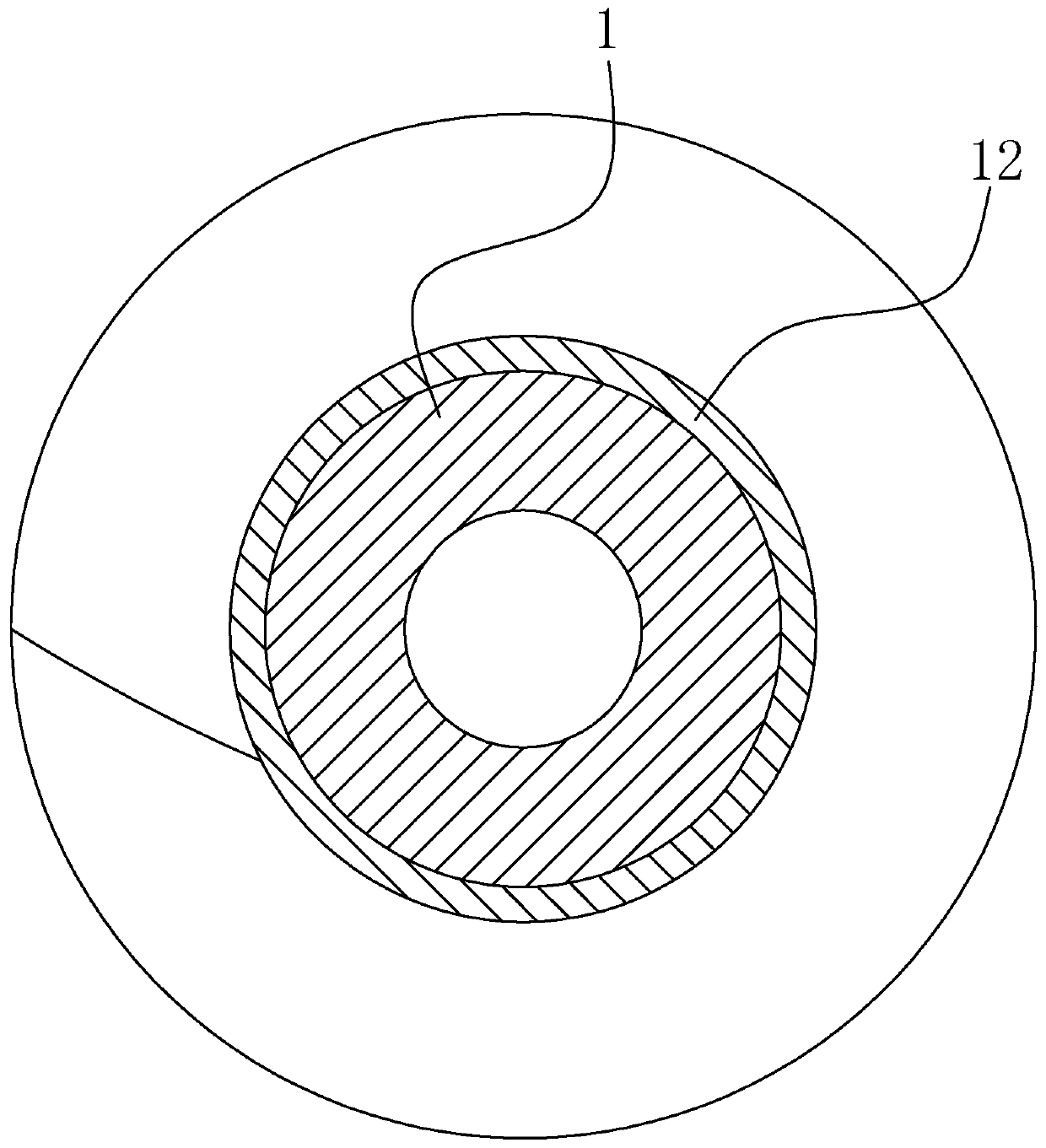

[0033] like Figure 1 to Figure 12 As shown, the conical screw of the present embodiment includes a tapered rod body 1 with a gradually reduced diameter and a screw flight arranged on the tapered rod body 1. The screw flight is divided into a feed section A, a melting section C, and a discharge section Section D, a transition section B is provided between the feed section A and the melting section C, the feed section A, the transition section B, the melting section C, and the helicoids of the discharge section D are arranged intermittently with each other, and the feed section The ratio of the length of A to the length L1 of the screw edge section on the tapered rod body 1 is 0.35 to 0.45. The feed section A is divided into the first section A1, the second section A2 and the third section A3, and the first section A1 , The screw flights of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com