Injection mould of locomotive toy series

A technology for injection molds and locomotives, which is applied in the field of injection molds for locomotive toy series. It can solve the problems of large equipment size, affecting the mold clamping of the upper and lower molds, and inconvenient use and replacement, and achieves the effects of high merging precision, energy saving, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

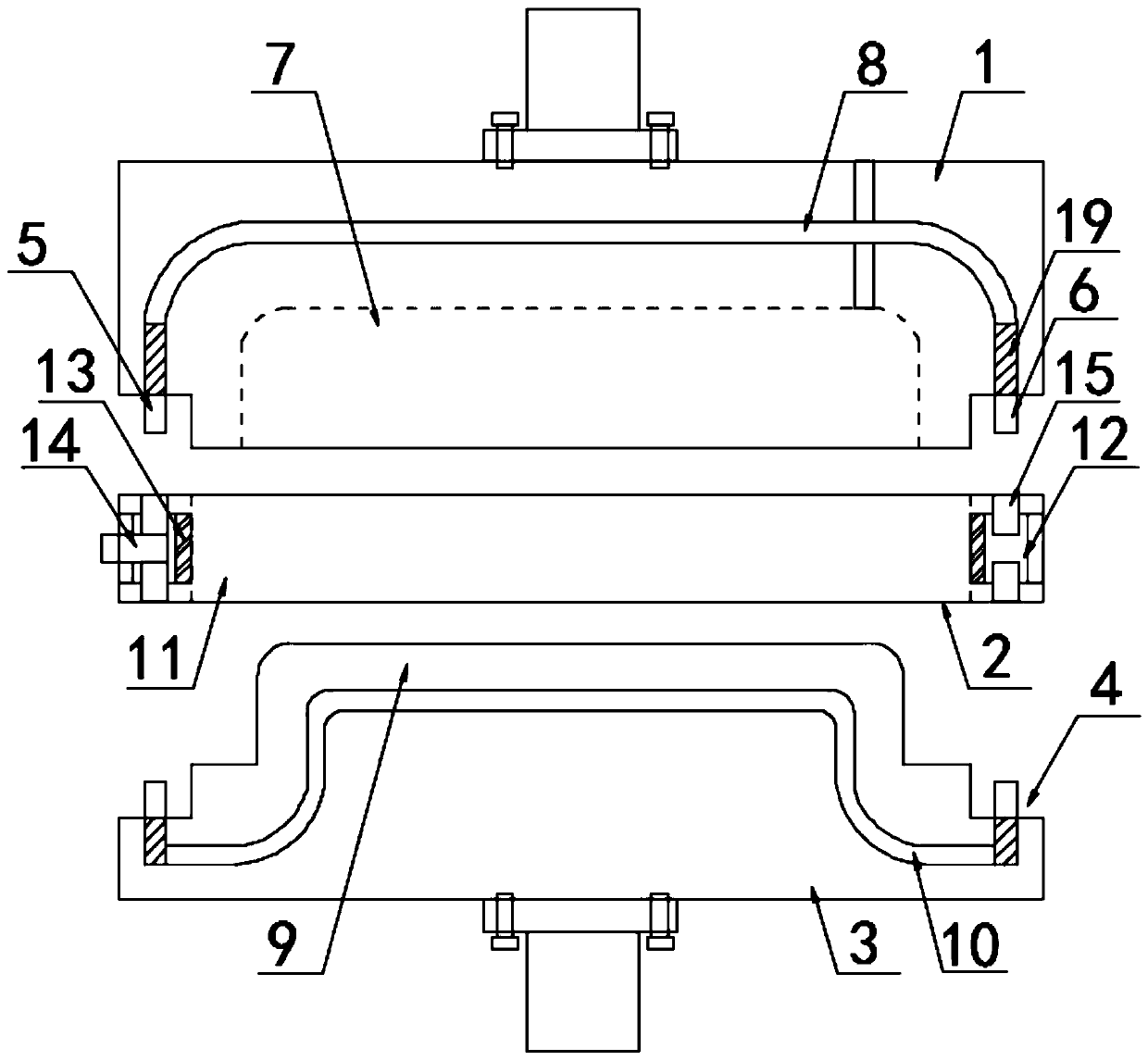

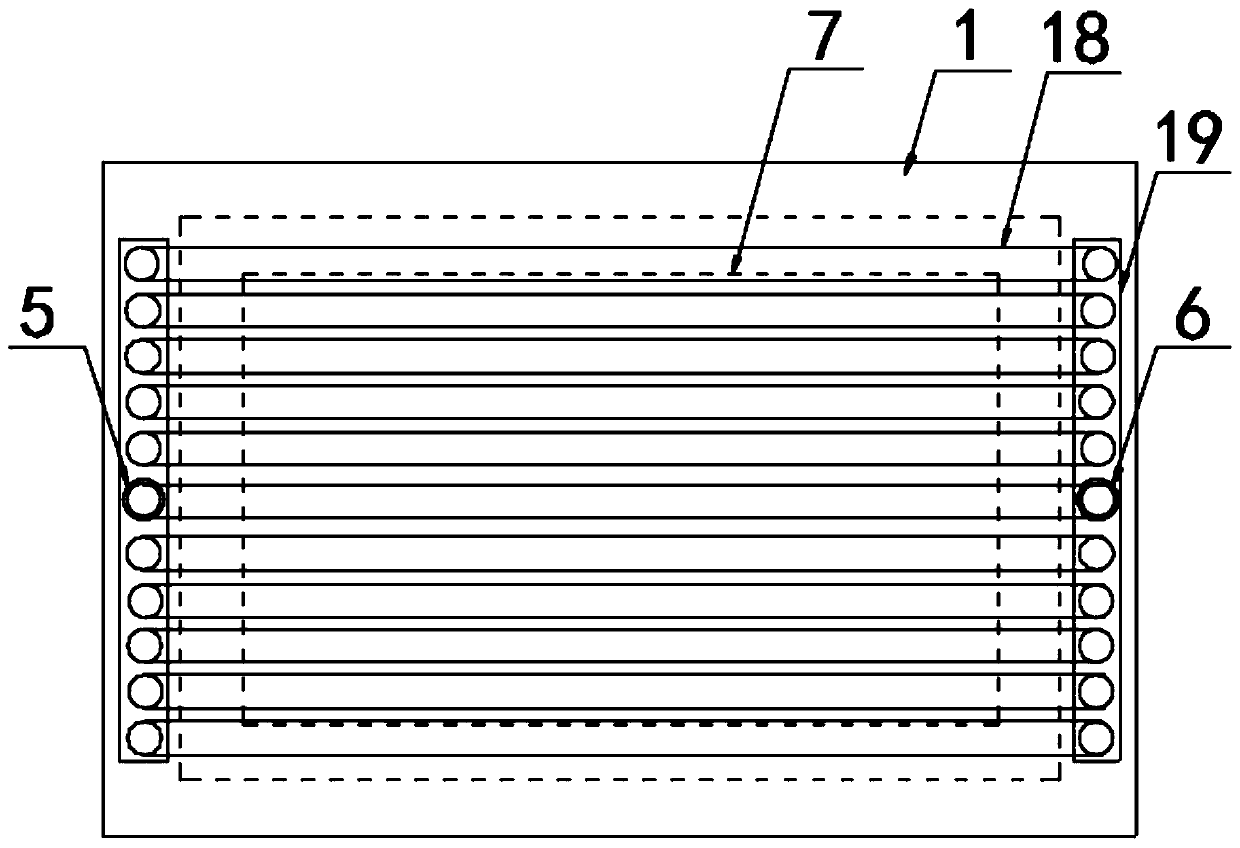

[0024] according to Figure 1-2 The injection mold of a locomotive toy series shown includes an upper mold 1, an intermediate cooling positioning frame 2 and a lower mold 3. The upper mold 1 and the lower mold 3 are respectively movably arranged on the top and bottom of the intermediate cooling positioning frame 2, so Both the bottom edge of the upper mold 1 and the top edge of the lower mold 3 are provided with a step 4, the step 4 is provided with a water inlet pipe 5 on one side and a water outlet pipe 6 on the other side, and the bottom surface of the upper mold 1 is provided with a mold groove 7. The upper mold 1 corresponding to the top of the mold cavity 7 is provided with an upper cooling system 8, the top of the lower mold 3 is integrally connected with a mold core 9, and the lower mold 3 corresponding to the bottom of the mold core 9 is provided with a lower mold 3 In the cooling system 10, a through groove 11 is provided on the inner side of the intermediate cooling p...

Embodiment 2

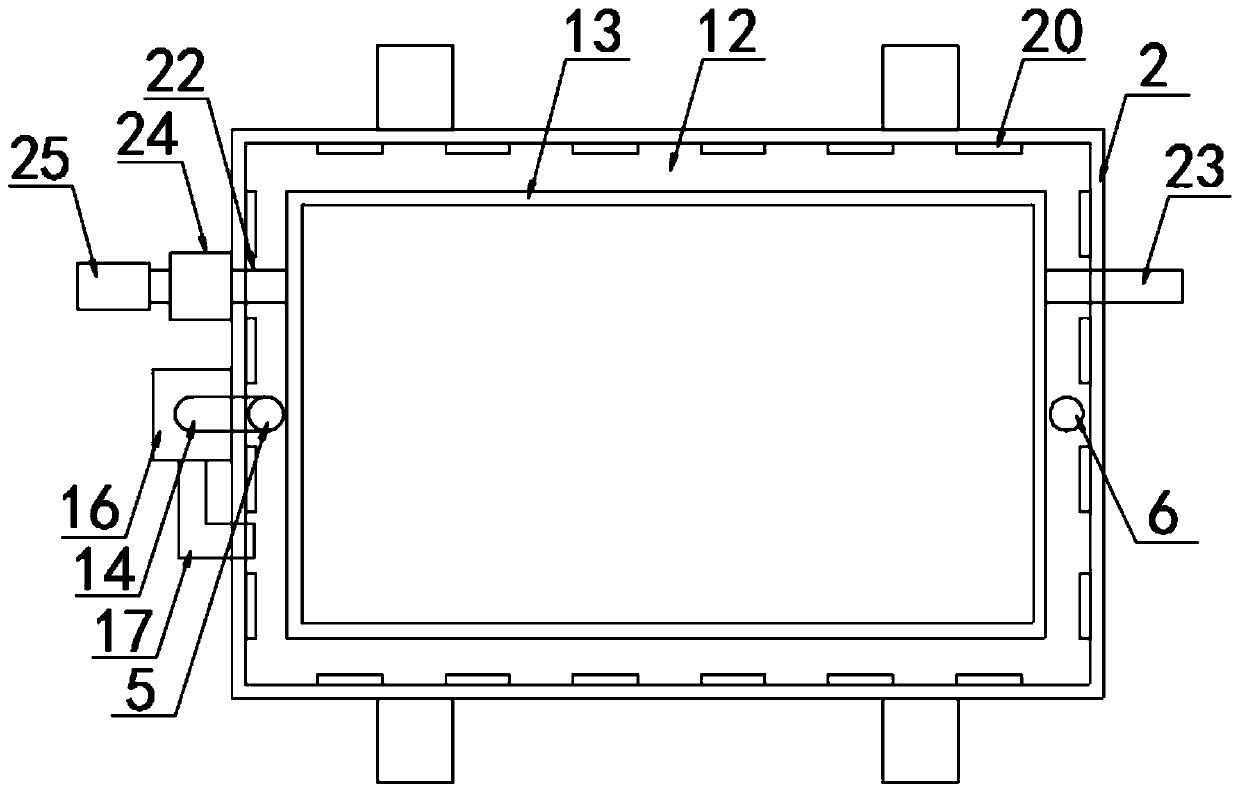

[0031] according to figure 2 In the injection mold of a locomotive toy series shown, the internal refrigeration channel 12 is arranged in a rectangular frame shape, and the inner and outer walls of the internal refrigeration channel 12 are provided with a semiconductor refrigeration fin 20. The inner and outer walls of the channel 12 are arranged in close contact, and the intermediate cooling positioning frame 2 is made of aluminum alloy material to facilitate the heat dissipation of the hot end of the semiconductor refrigeration fin 20;

[0032] according to figure 2 In the injection mold of a locomotive toy series shown, one side of the outer refrigeration channel 13 is provided with an air inlet pipe 22 and the other side is provided with an air outlet pipe 23. Both the air inlet pipe 22 and the air outlet pipe 23 penetrate the inner refrigeration channel 12 And the outer wall of the intermediate cooling positioning frame 2 and extending to the outside of the intermediate coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com