Full-automatic tapping machine capable of recycling scraps

A fully automatic, tapping machine technology, applied in the direction of thread cutting machine, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of affecting work efficiency, difficult waste disposal, cumbersome operation, etc., to reduce work intensity and structure Simplicity and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

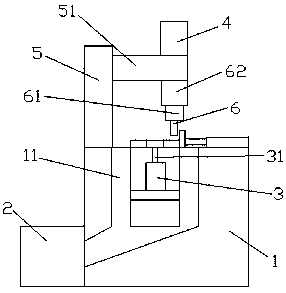

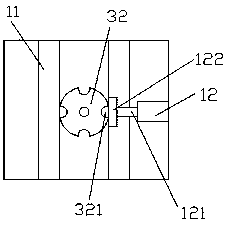

[0015] As a preferred embodiment of the present invention, the first motor 3 is arranged in the middle of the base 1 and is fixedly connected with the base 1, the working disc 32 is arranged in the middle of the upper end of the base 1, and Through the rotating shaft 31 and the first motor 3, the working semi-circular hole 321 is opened on the outer side of the front of the working disc 32; The middle of the upper right side of the seat 1 is fixedly connected with the machine base 1, the pressure head 122 is arranged on the right side of the working semicircular hole 321, and is movably connected by the telescopic rod 121 and the telescopic arm 12; the support column 5 It is arranged in the middle of the left side of the upper end of the machine base 1, and is fixedly connected with the machine base 1, and the second motor 4 is arranged at the upper side of the working disk 32, and is fixedly connected by the support rod 51 and the support column 5; The tapping head 6 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com