Solar energy heat collecting tube with film photovoltaic power generation coupling selective absorption coating

A solar collector tube and absorbing coating technology, applied in solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of complex structure and process, difficulty in large-scale production, low comprehensive efficiency, etc. Low cost, effect of increasing voltage or current, reducing structural complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Some specific embodiments of the present invention will be described in detail below in an exemplary and non-limiting manner with reference to the accompanying drawings. The same reference numerals in the drawings designate the same or similar parts or parts. It should be understood by those skilled in the art that these drawings are not necessarily drawn to scale.

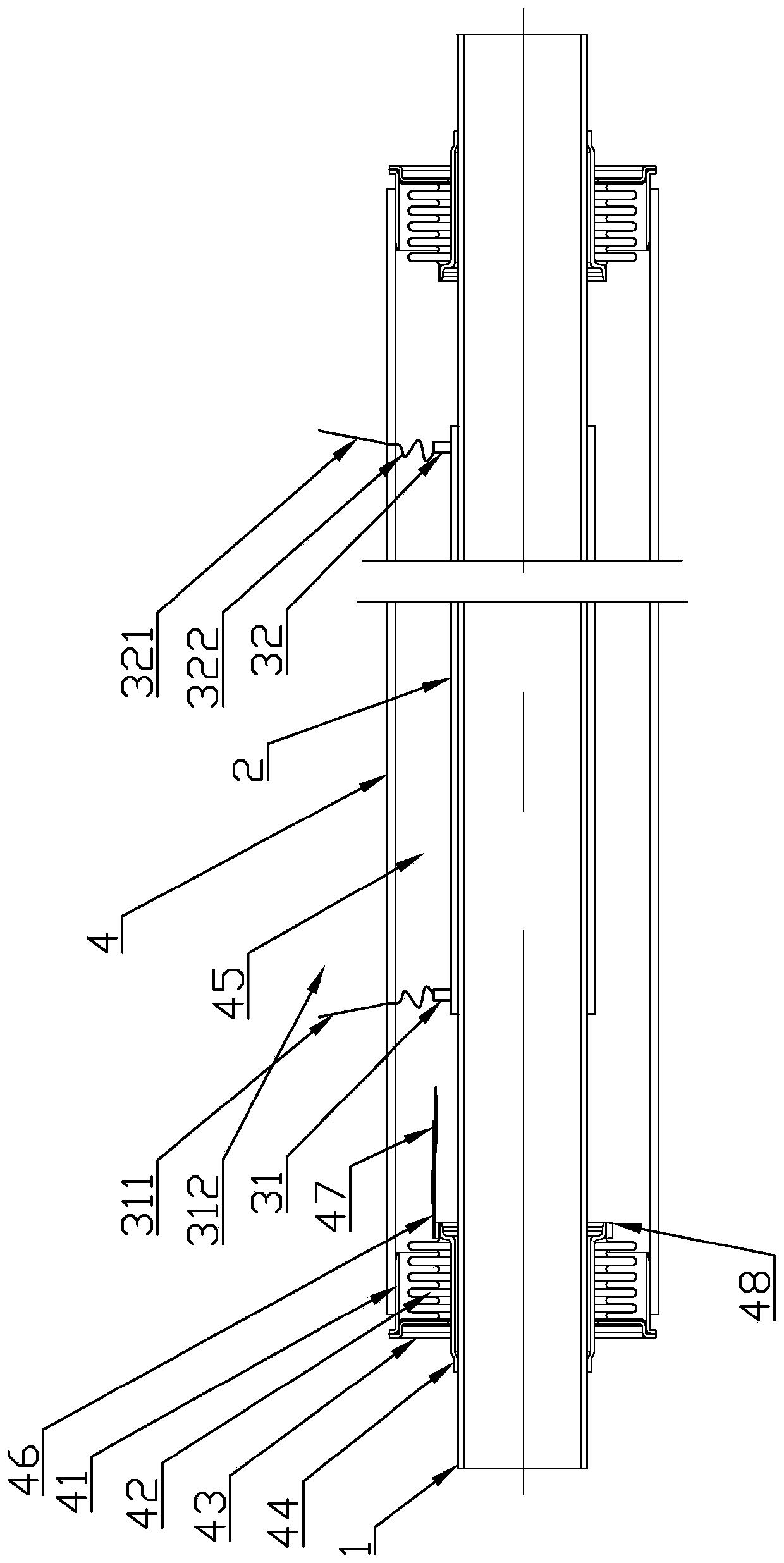

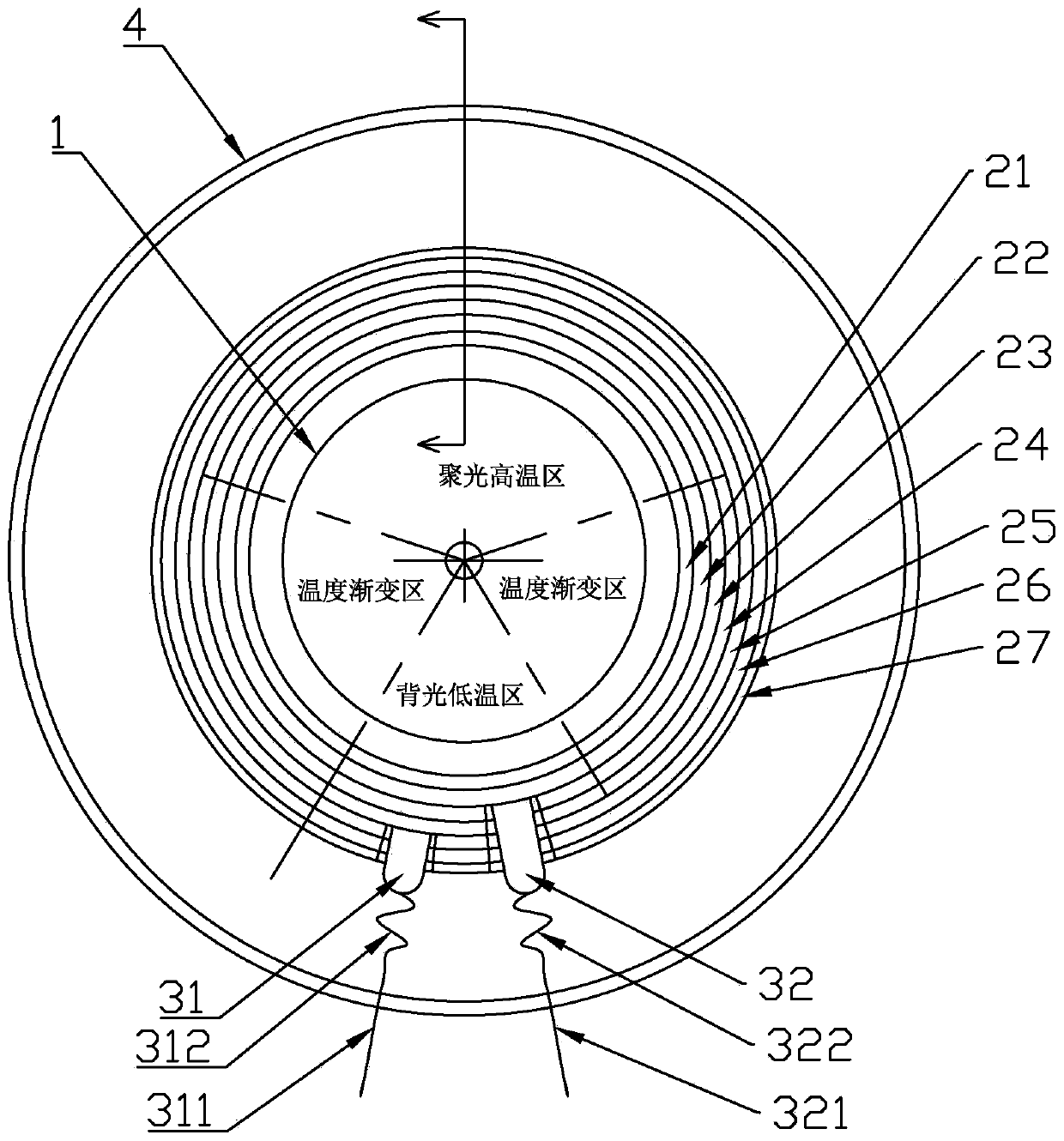

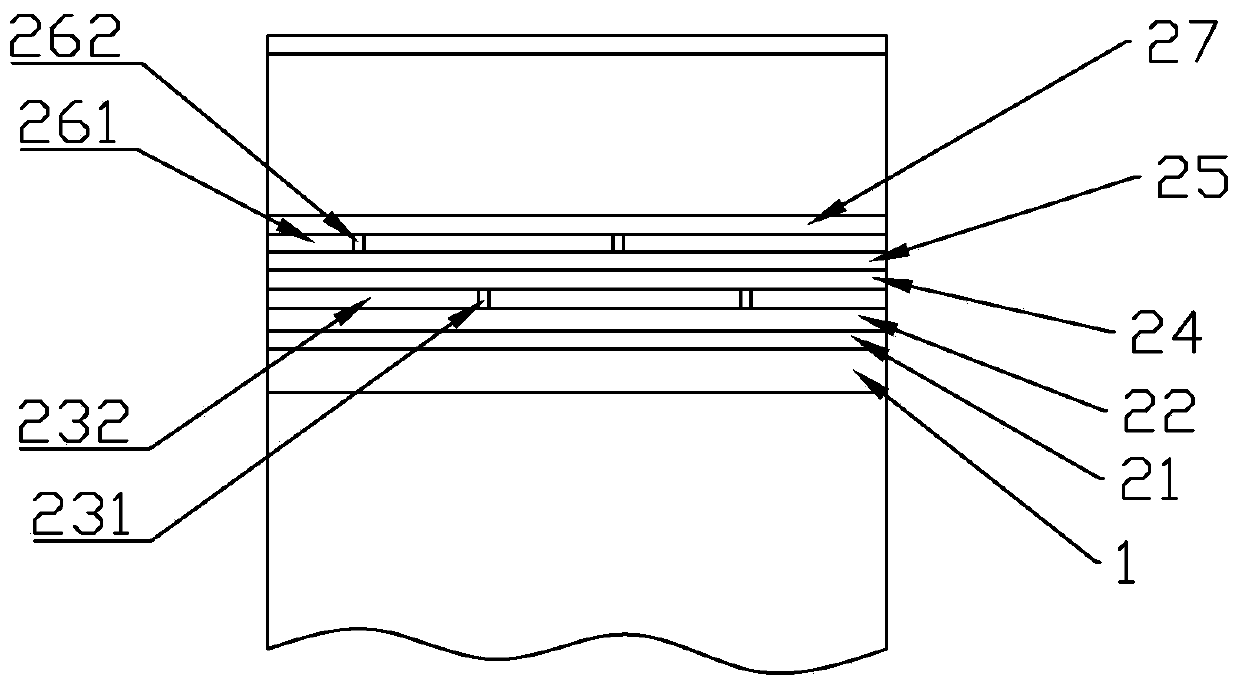

[0037] Such as figure 1 , figure 2 Shown is a longitudinal sectional view and a transverse sectional view of a solar collector tube with a thin-film photovoltaic power generation coupling selective absorption coating structure provided by the present invention. The thermal collector tube includes:

[0038] Steel pipe 1, the fluid to be heated circulates in the pipe, the outer wall is provided with the thin film photovoltaic power generation coupling selective absorption coating structure 2 (the specific structure will be described in detail later), and the coating structure 2 is also connected with the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com