Non-concentric elastic compensation sealing assembly

A technology of elastic compensation and sealing components, which is applied in the direction of engine sealing, conveyor objects, engine components, etc., can solve the problems of poor non-contact sealing effect, affecting sealing and operation effect, reducing sealing performance, etc., and achieves low cost , Reliable axial compensation, convenient installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

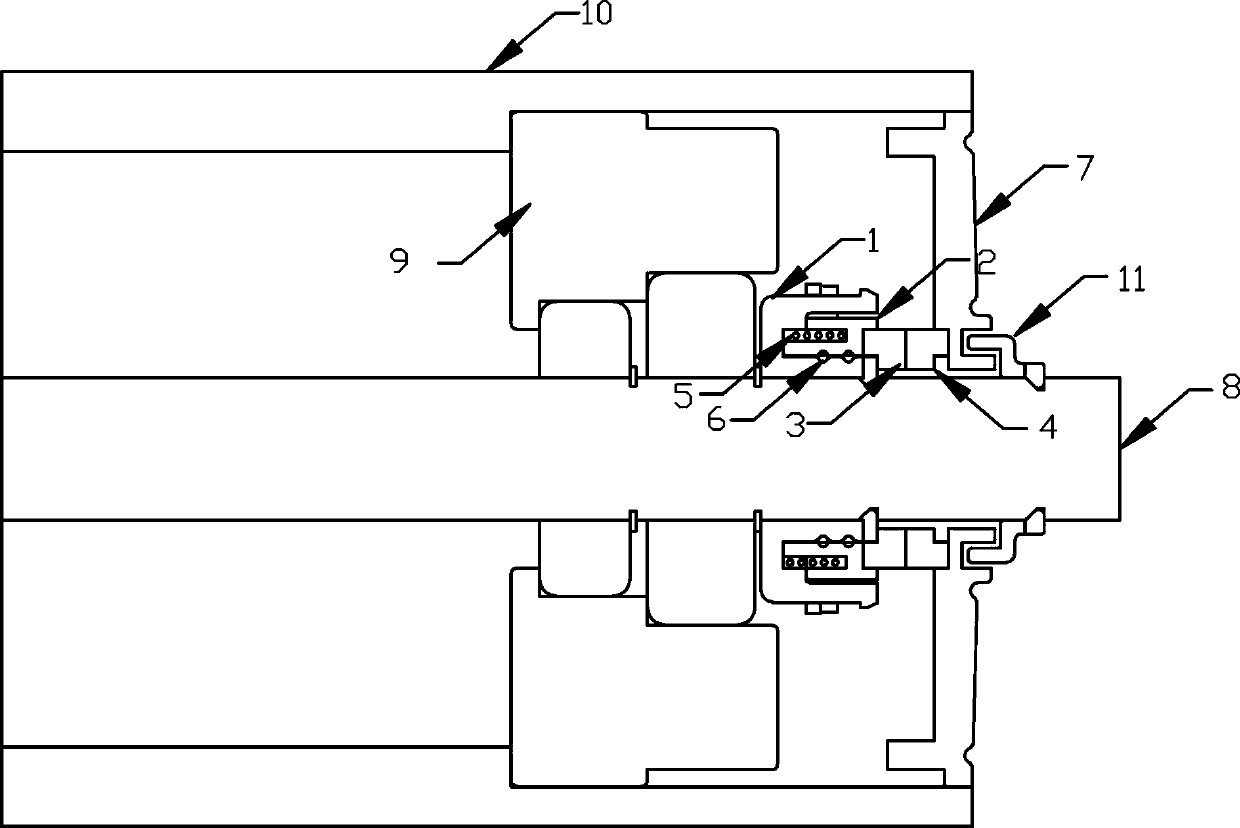

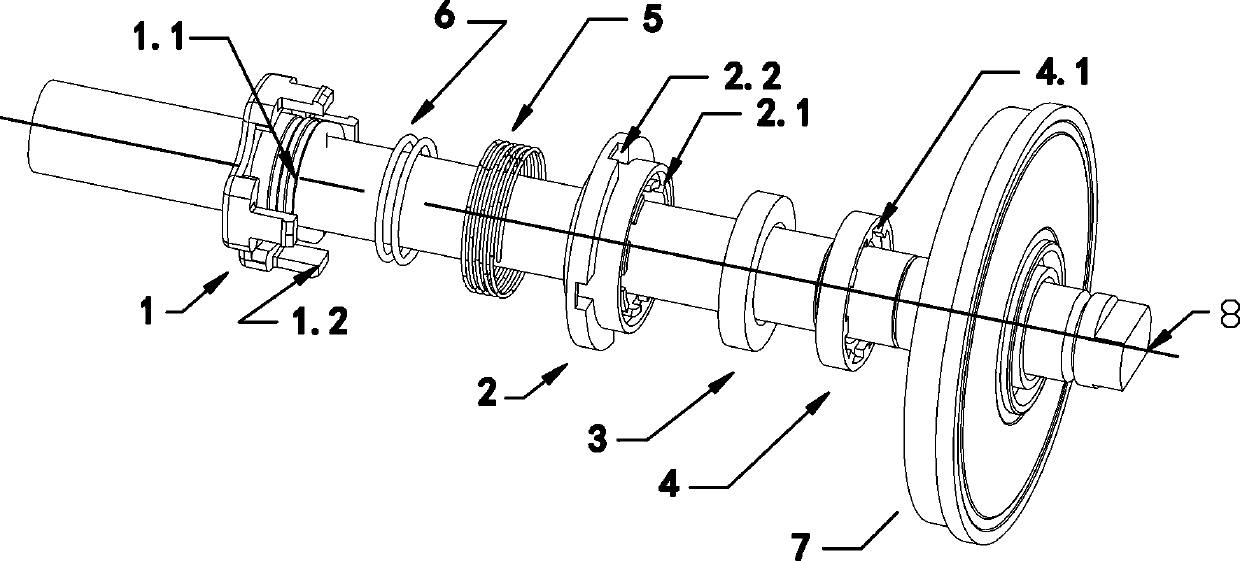

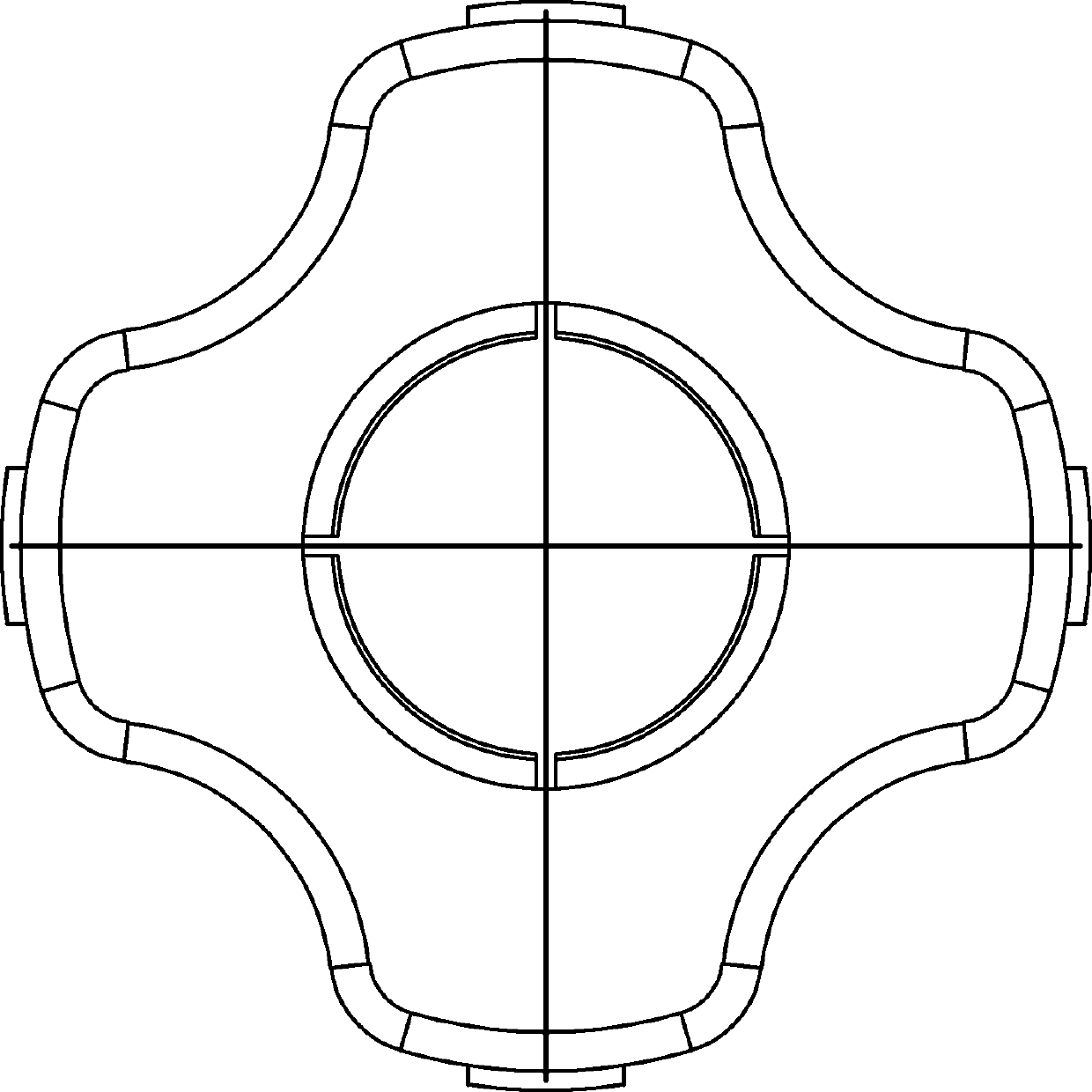

[0042] Such as figure 1 As shown, install the bearing chambers 9 at both ends of the idler cylinder 10, and then follow the figure 2 In the sequence shown, the static sleeve 1 is tightly fitted and pressed into the shaft 8, positioned and fixed on the outside of the bearing chamber 9, and will not move axially and rotationally, as shown in Figure 3-5 The shown static sleeve 1 is designed with a sealing ring groove 1.1 and elastic elastic teeth 1.2, and the sealing ring 6 is tightly fitted into the sealing ring groove 1.1 on the static sleeve 1 without moving, and the spring 5 is inserted into the static sleeve 1 on the inner side of the elastic teeth 1.2, such as Figure 6-8 The moving sleeve 2 shown is designed with an anti-rotation groove 2.1 and an elastic tooth hole 2.2. Insert the elastic tooth hole 2.2 on the moving sleeve 2 into the elastic tooth 1.2 on the static sleeve 1, and the anti-rotation groove 2.2 on the elastic tooth 1.2 The tooth removal has a certain deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com