Aluminum alloy for high strength die casting, method of manufacturing the same, and method of manufacturing aluminum alloy casting products

A manufacturing method and high-strength technology, applied in the fields of high-strength die-casting aluminum alloy and its preparation and aluminum alloy casting manufacturing, can solve problems such as poor corrosion resistance and surface corrosion, achieve excellent corrosion resistance, improve life, and ensure safety. effect on performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

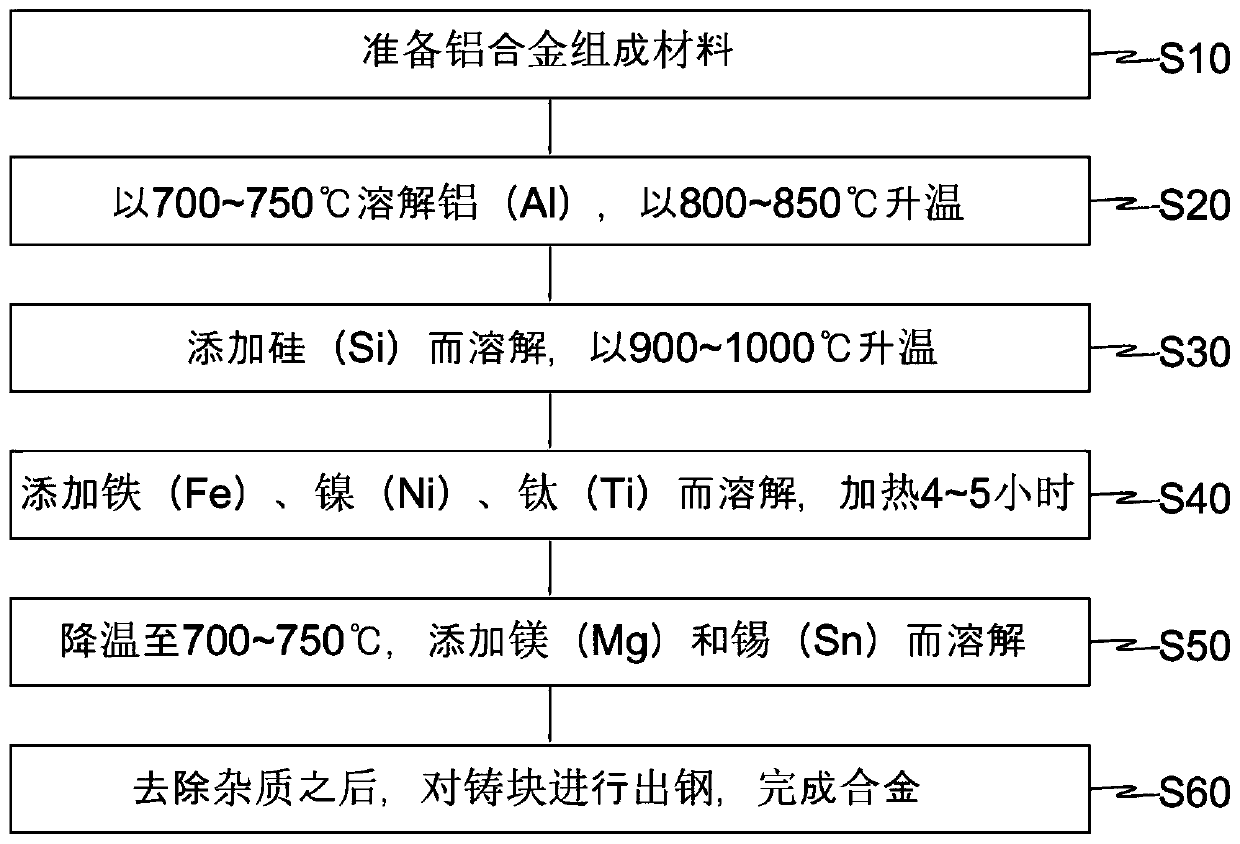

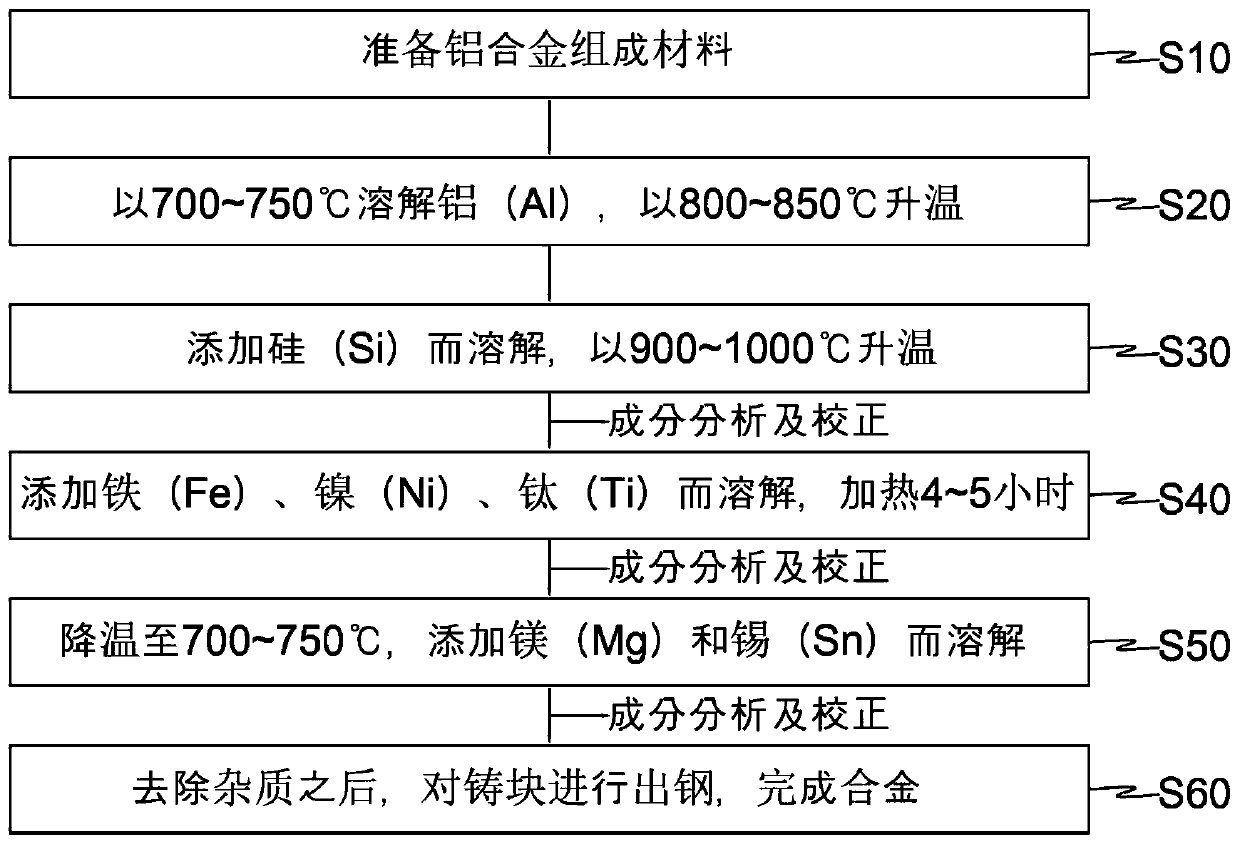

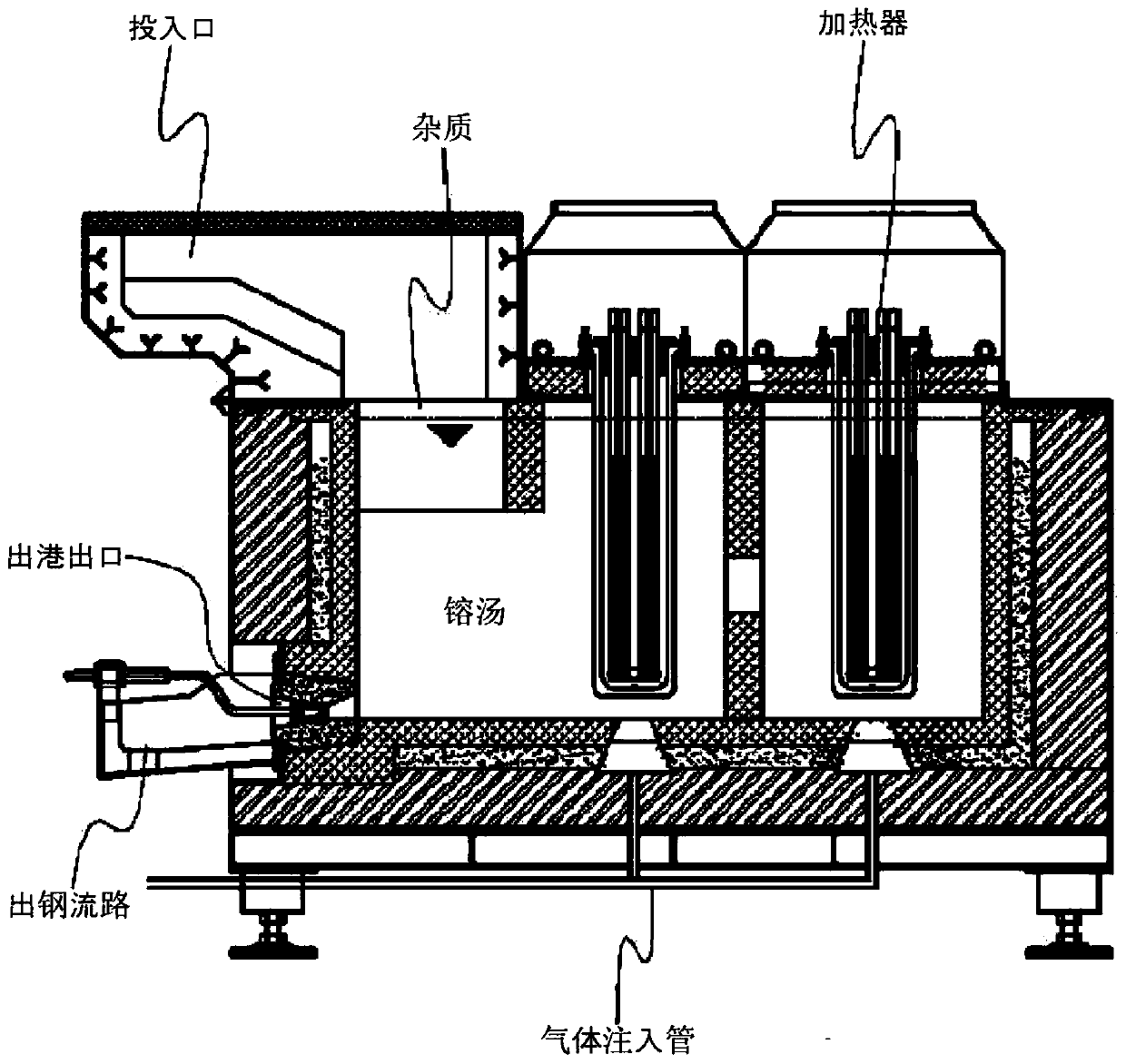

[0039] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0040] One aspect of the present invention relates to an aluminum alloy, which is composed of silicon (Si), iron (Fe), magnesium (Mg), nickel (Ni), titanium (Ti), tin (Sn), and the remainder aluminum (Al). Aluminum alloy for die casting in order to achieve high strength with high corrosion resistance and high thermal conductivity at the same time.

[0041] Silicon (Si) improves fluidity and strength, and is preferably included in the range of 5.0 to 7.0 weight percent relative to the total weight of the alloy. That is, if silicon is more than 7.0% by weight, the heat treatment is poor and may be broken, and if it is less than 5.0% by weight, the original purpose cannot be achieved. Therefore, it is most preferable to include 6.0 weight percent so that both fluidity and strength and heat treatment can be improved.

[0042]Iron (Fe) prev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com