Square and round object hoisting tong device and hoisting method thereof

A lifting tong and weighing device technology, applied in the directions of safety devices, transportation and packaging, load hanging components, etc., can solve the problems of unguaranteed safety, poor flexibility, complicated operation, etc., to maximize economic benefits and improve Lifting efficiency and the effect of simplifying worker operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

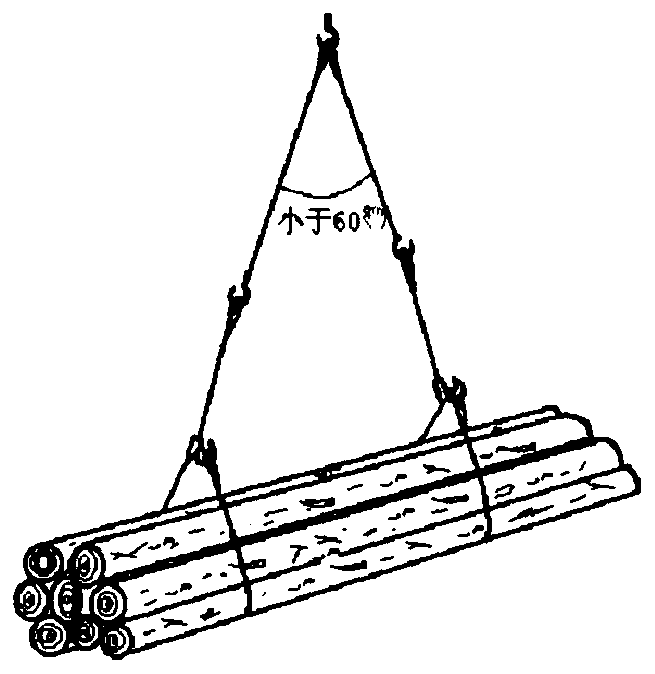

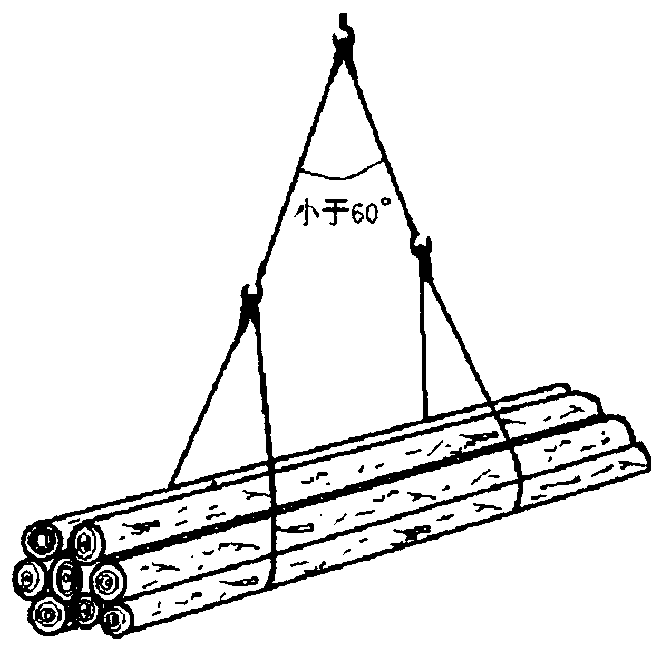

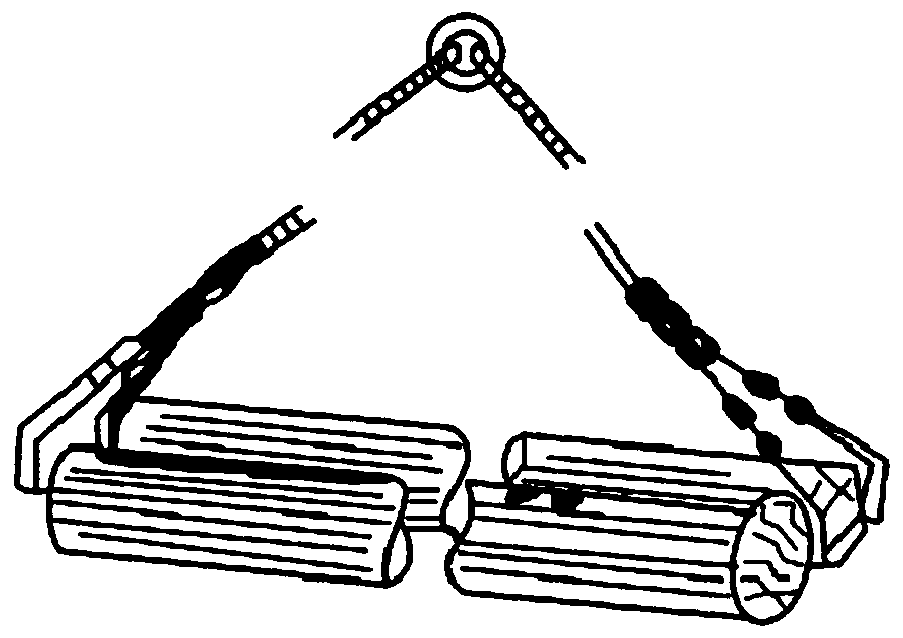

[0047] The basic idea of the present invention is: according to the characteristics of timber (round and square) hoisting operation, by multiple clamping tongues, clamp body, blocking plate, compactor, overload alarm device (tension sensor, and buzzer controlled by single-chip microcomputer) Functional integration makes it work together as a whole, adjusts the clamper according to the shape and size of the clamped wood, and locks the clamp tongue downward through the weight of the wood, so that both round wood and square wood can be effectively clamped ;By increasing the overload alarm device, it is composed of a buzzer controlled by a single-chip microcomputer, and when the added load exceeds the standard, an alarm is sent to improve the safety and practicability of the lifting clamp. The specific structure is described as follows:

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com