Uniform material scattering method and device for dried vegetable scraps

A uniform and bulk material technology, applied in the directions of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problems of low product quality, increased labor intensity, unevenness, etc., to ensure the effect of bulk materials, reduce effectively The effect of area, good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

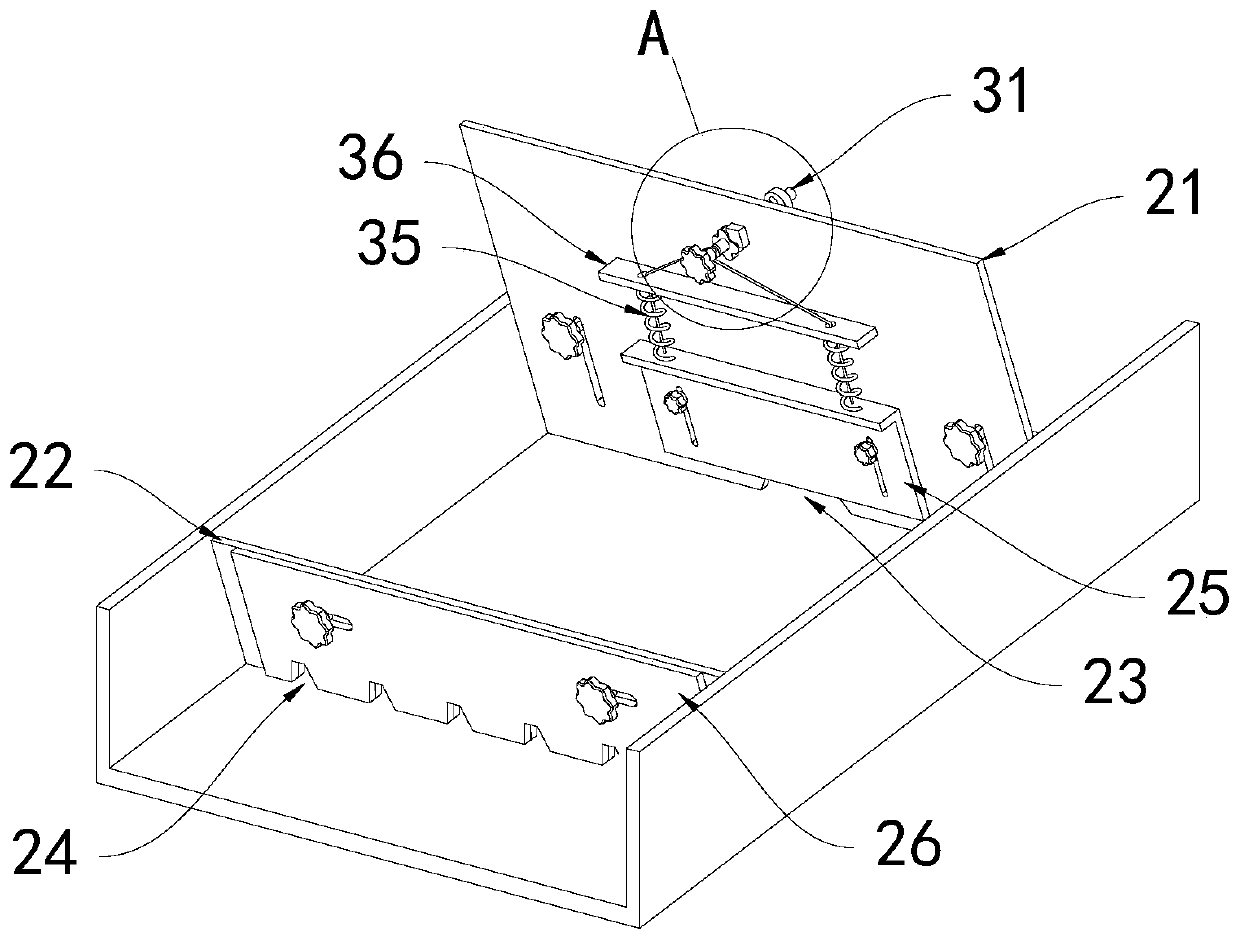

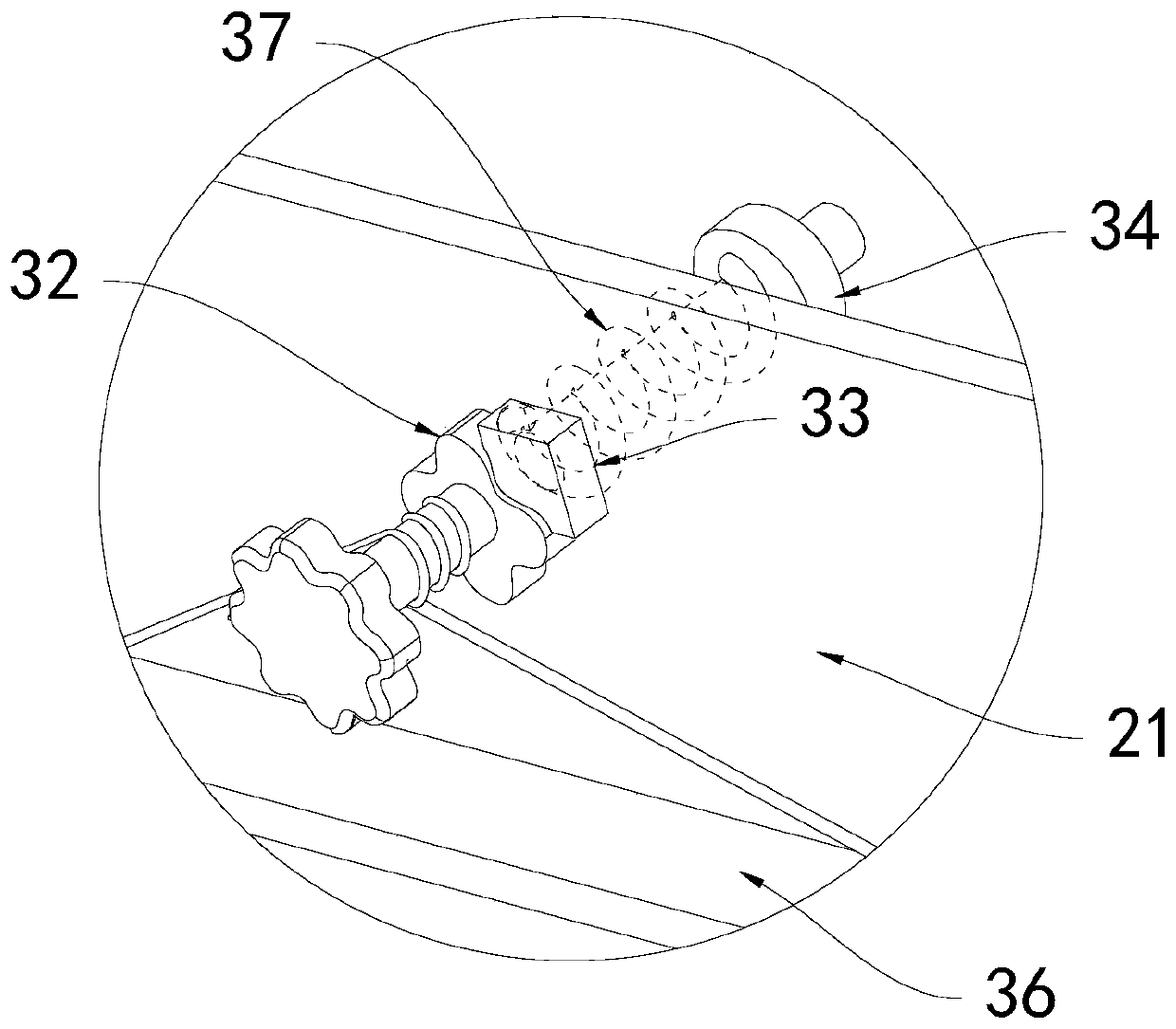

[0032] Embodiment: A method for uniformly bulking dry and crushed vegetables, by setting uniform material holes uniformly distributed along the width direction of the path on the flow path of the material, so that the material is evenly distributed in the width direction of the flow path after flowing through the uniform material holes ; the flow path is in a vibrating working condition; in the method for uniform bulk material, the flow path is also provided with a large material hole in the middle of the width direction, and the material first flows through the large material hole and then disperses and flows through the uniform material hole. feed hole.

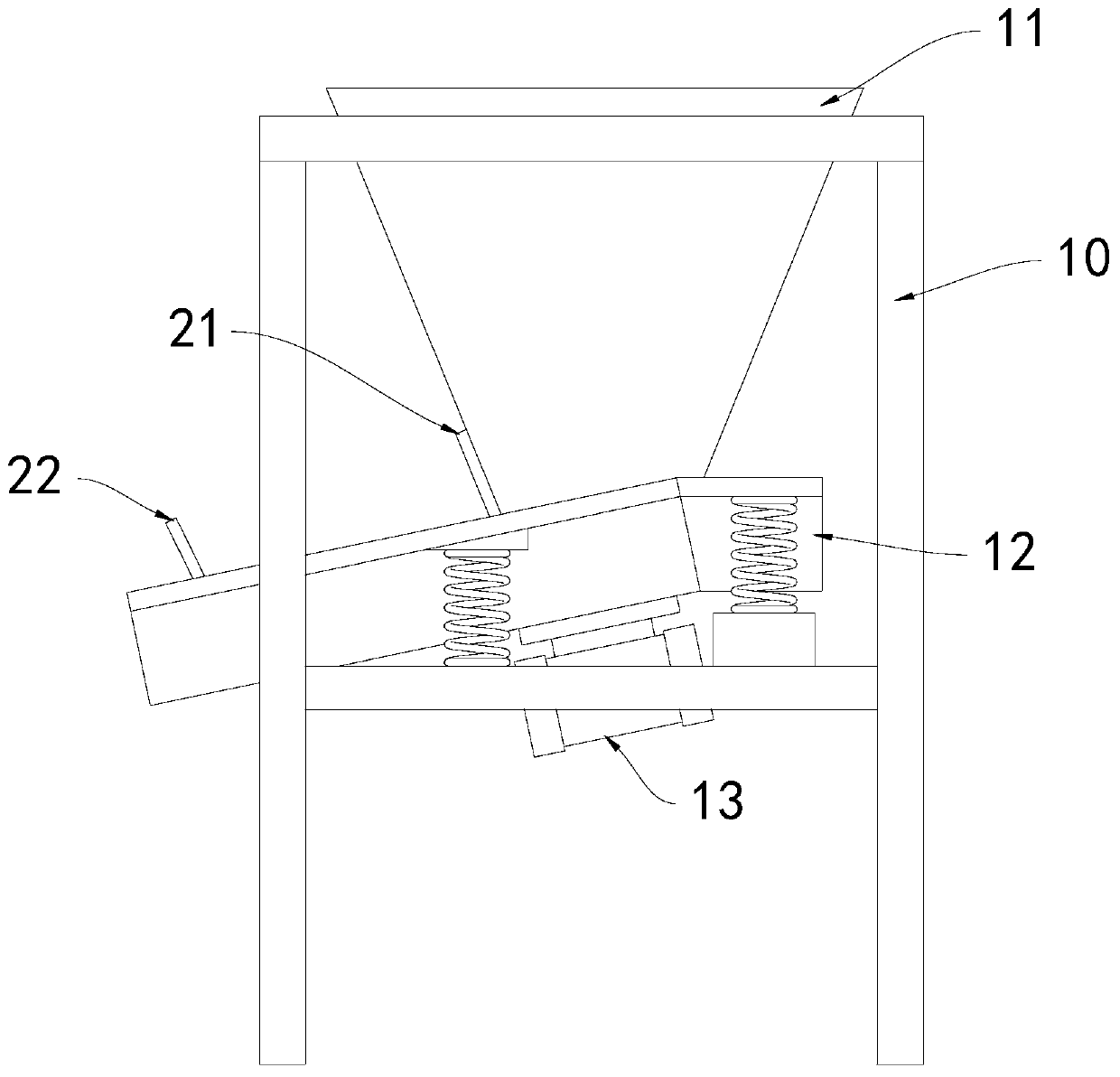

[0033] A device for realizing the method of uniformly bulking dry and crushed vegetable products, the composition of which is as follows Figure 1 to Figure 4 Shown, comprise frame 10, frame 10 tops are provided with hopper 11, and frame 10 bottoms are provided with the ramp 12 that cooperates with hopper 11, and ramp 12 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com