Supporting tool for machining and method for machining tensioning sleeve by using supporting tool

A technology of tensioning sleeves and expansion sleeves, which is applied in the direction of manufacturing tools, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces. and shape and position tolerances, etc., to reduce deformation, reduce the magnitude of deformation, and improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention will be further described:

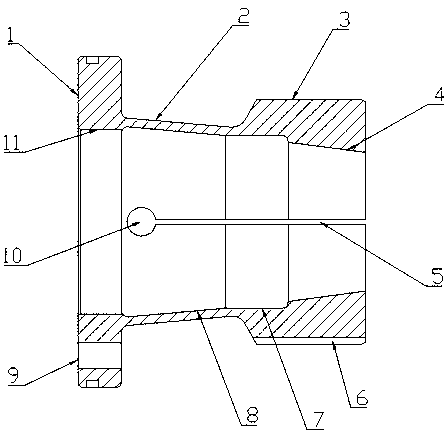

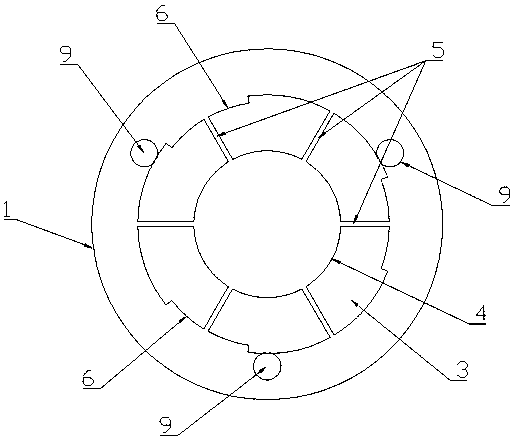

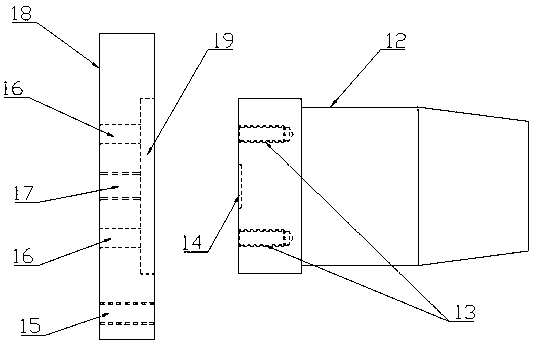

[0036] Such as Figure 1~6 As shown, the present invention provides a brace for processing, which includes a base 18 and a support body 12. The end surface of the base 18 is provided with a mounting groove 19. After the support body 12 is inserted into the mounting groove 19, a screw ( not shown) connection, at the central axis where the base 18 and the support body 12 are connected, the base 18 is provided with a threaded through hole 17, corresponding to the port of the threaded through hole 17, and the support body 12 is provided with a groove 14, preferably, as Figure 3~5 As shown, the support body 12 is provided with four blind holes 13, and the blind holes 13 are evenly distributed in a ring around the groove 14, and the base 18 is provided with threaded holes 16 corresponding to the blind holes 13, and screws (not shown) pass through The threaded via holes and bli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com