Method for detecting load current

A load current and voltage technology, applied in the direction of measuring current/voltage, measuring electrical variables, measuring devices, etc., can solve the problem of large load current detection error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

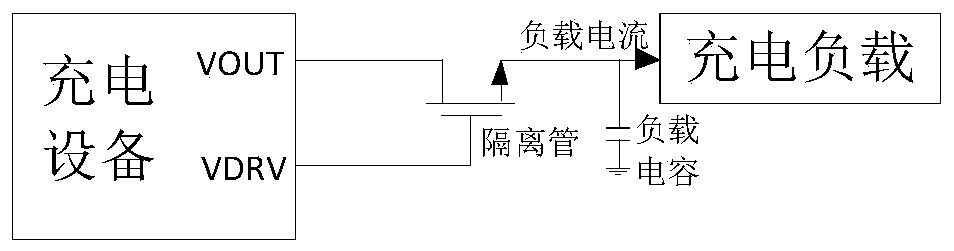

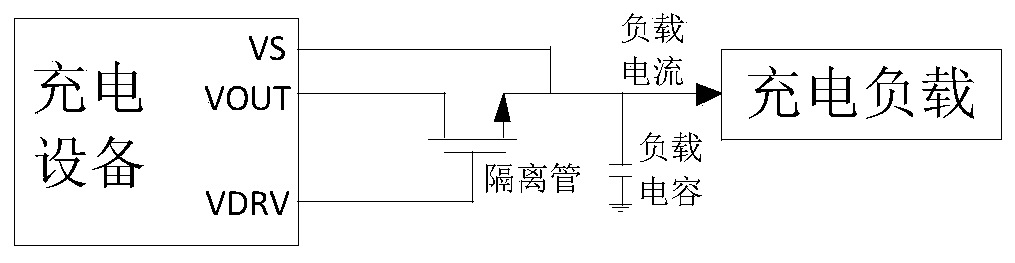

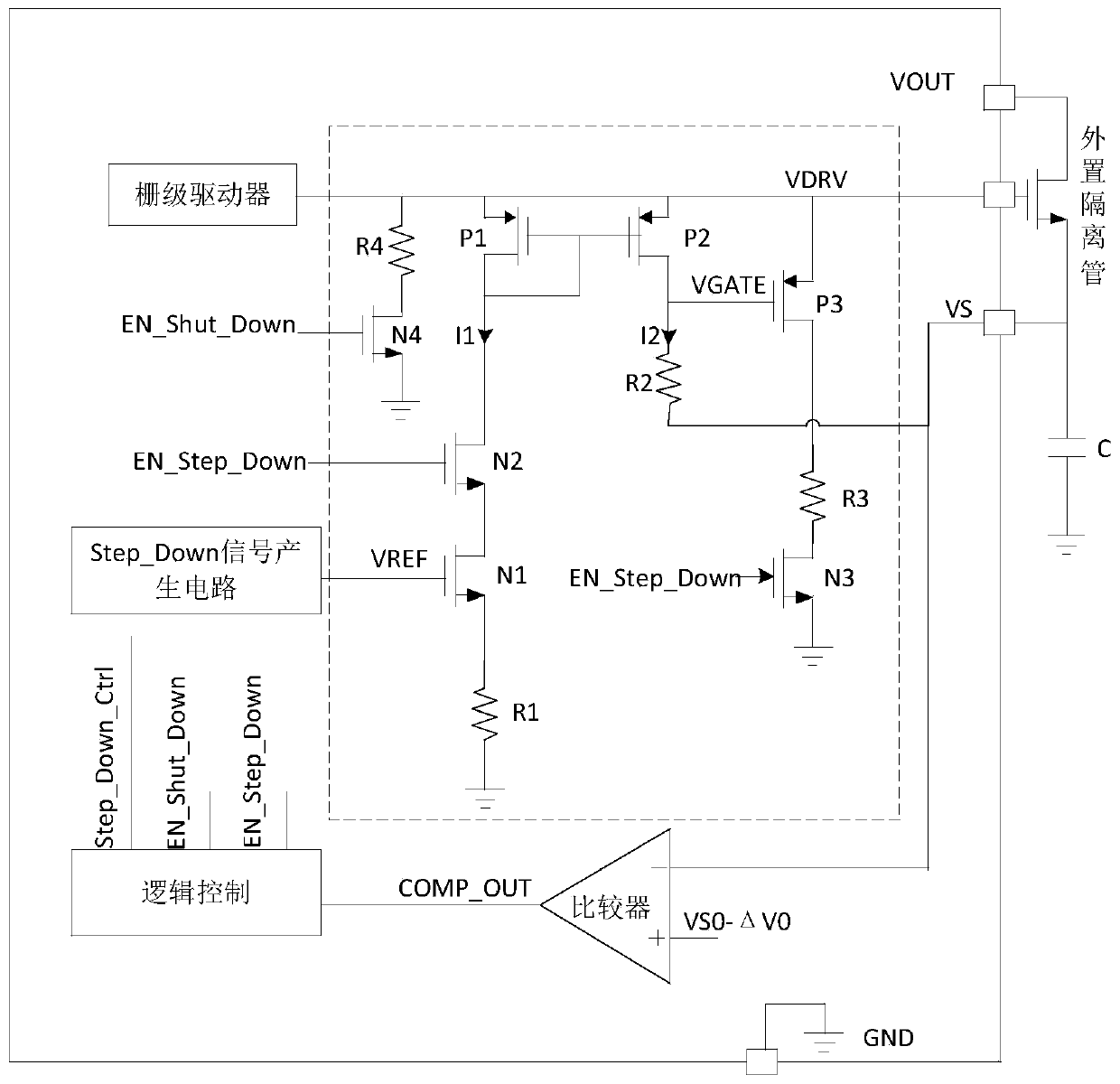

[0023] Such as Figure 1 to Figure 7 As shown, a method for detecting load current includes a control circuit for detecting load current, the control circuit includes a comparator, a logic control circuit connected to the COMP_OUT terminal of the comparator, and a signal generation circuit connected to the Step_Down_Ctrl pin of the logic control circuit , a signal generation circuit connected to the logic control circuits EN_Shut_Down and EN_Step_Down and an isolation tube grid control circuit, a gate driver connected to the isolation tube grid control circuit, an external isolation tube connected to the grid and the isolation tube grid control circuit, One end is connected to the drain of the external isolation tube, the other end is grounded and the capacitor C is connected to the external load, connected to the positive input of the comparator and passed the threshold voltage VS0-ΔV0 of the set voltage threshold, and connected to the comparator at the same time through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com