Fast optical correction method

An optical calibration and fast technology, applied in the field of optical calibration, can solve problems such as laborious, time-consuming, and inability to guarantee calibration accuracy, and achieve the effect of great promotion value, convenient calibration, and reducing the probability of panel missed and wrong detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

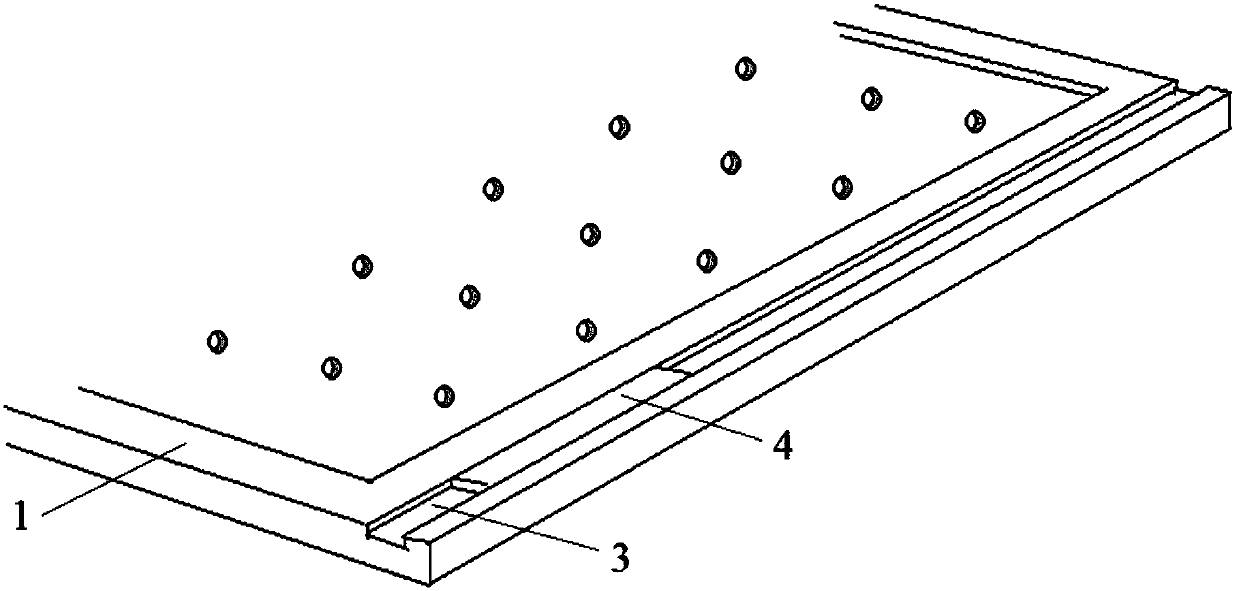

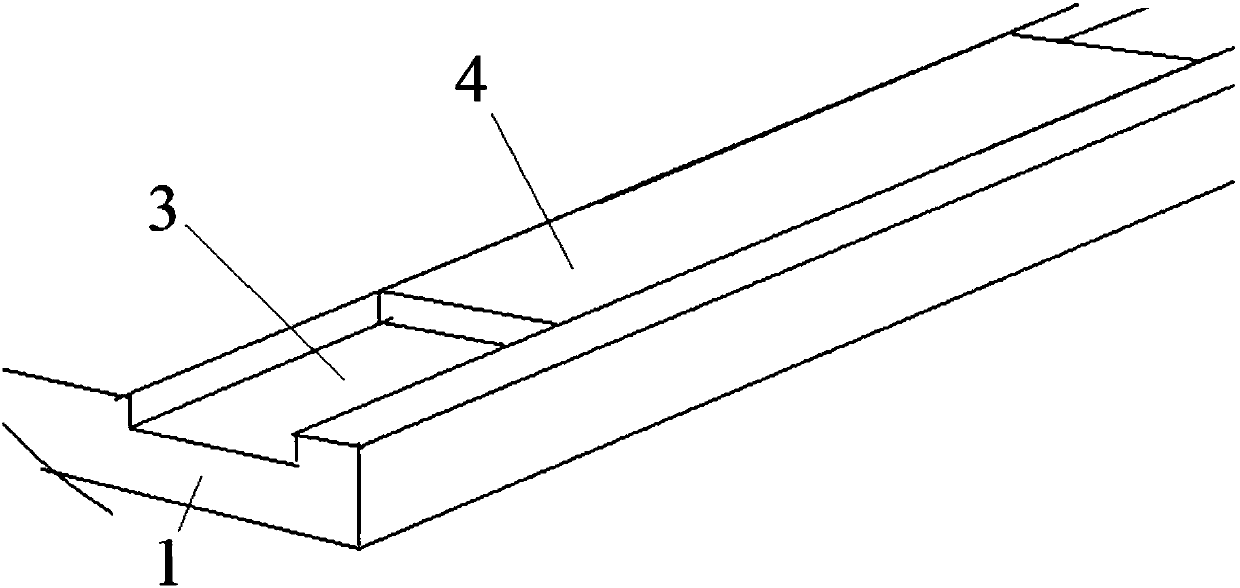

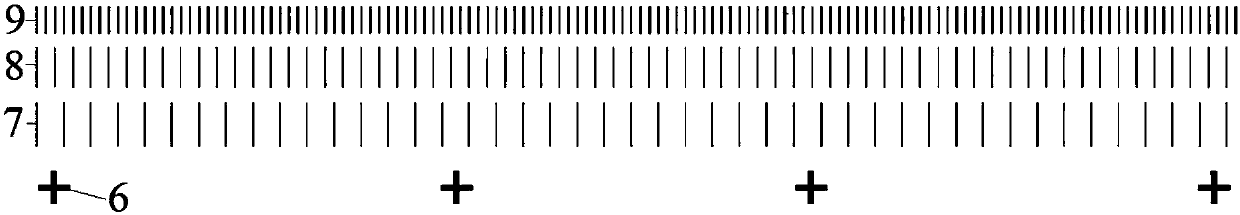

[0028] Such as Figure 1~4 , a fast optical calibration method, including a stage 1, the stage 1 is detachably mounted on a detection platform (carrying a test object) of a detection device. In this embodiment, a chute 3 arranged along the arrangement direction of a plurality of CCD cameras 2 is provided on the stage 1, the depth, straightness and flatness of the chute 3 are less than ±10 microns, and the chute 3 is a groove with an upper opening Slot structure, a correction plate 4 is placed in the chute 3 and can slide along the length direction of the chute 3, and the surface of the correction plate 4 is on the same plane as the surface of the detection platform. The correction plate 4 is a crystal glass substrate, and its length, width and height are 120 mm * 20 mm * 4.3 mm. The width of the correction plate 4 is about 100 micron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com