Synthesis of hyperbranched epoxy resin and application in waterproof rolls

An epoxy resin and reaction technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of peeling strength drop, detachment from the base layer, etc., to achieve the effect of controlling production cost, easy availability of raw materials, and improving peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

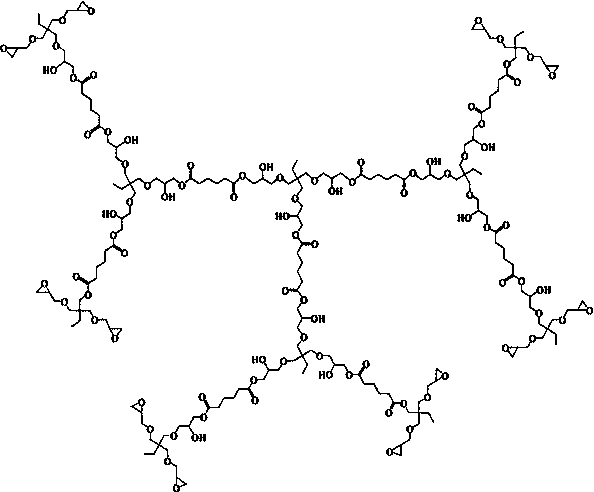

Image

Examples

Embodiment 1

[0018] Add 3.0236g of trimethylolpropane triglycidyl ether into a four-necked flask with a stirrer condenser, then add 1.0961g of adipic acid and 0.0206g of triphenylphosphine, raise the temperature to 120°C, and react for 5 hours to obtain the obtained product Describe the first generation hyperbranched epoxy resin.

Embodiment 2

[0020] Add 9.8276g of trimethylolpropane triglycidyl ether into a four-necked flask with a stirrer condenser, then add 4.3842g of adipic acid and 0.0711g of triphenylphosphine, raise the temperature to 120°C, and react for 7 hours to obtain the obtained product Describe the second generation hyperbranched epoxy resin.

Embodiment 3

[0022] Add 30.2360g of trimethylolpropane triglycidyl ether into a four-necked flask with a stirrer condenser, then add 14.2487g of adipic acid and 0.2224g of triphenylphosphine, raise the temperature to 120°C, and react for 9 hours to obtain the obtained product Describe the third generation hyperbranched epoxy resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com