A repairing agent dry mixture for quick maintenance of cement pavement

A dry mixing and cement pavement technology, applied in the field of construction, can solve the problems of long time required for health preservation, large demand for consumables, complicated construction methods, etc., and achieves the effect of reducing the demand for consumables, simplifying the steps of the construction method, and forming fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

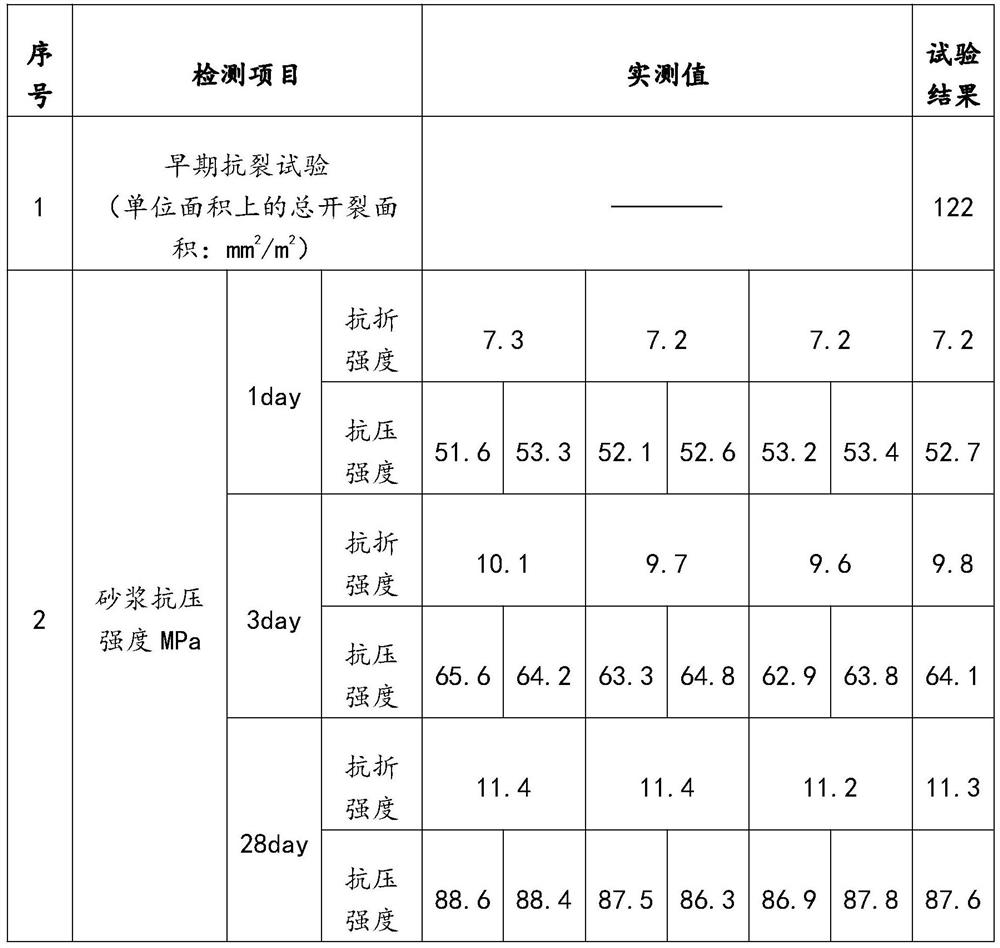

Embodiment 1

[0026] The repairing agent dry mixture used for rapid maintenance of cement pavement provided by this embodiment is composed of 320 to 450 parts of Portland cement (all Portland cement clinker mainly composed of calcium silicate) in parts by weight. , less than 5% limestone or granulated blast furnace slag, a hydraulic cementitious material made by grinding an appropriate amount of gypsum, collectively referred to as Portland cement, also collectively referred to as Portland cement internationally), 324-417 grading ( Grading refers to the distribution of particle sizes of aggregates at all levels, which can be determined by sieve analysis tests) river sand, 170 to 260 parts of graded crushed stone (referring to the mixture composed of aggregates of various sizes and different sizes, when its When the gradation meets the requirements of the technical specification, it is called a graded aggregate), 12.7-17 parts of silica fume, 3.2-8 parts of fly ash (which is the fine ash colle...

Embodiment 2

[0054] This example provides a formula for the further preferred component dosage of the repair agent dry mixture described in Example 1, that is: in parts by weight, it consists of 354-423 parts of Portland cement, 348-402 parts Graded river sand, 207-238 parts of graded gravel, 13.5-16.2 parts of silica fume, 4.5-7.2 parts of fly ash, 0.3-1.8 parts of calcium formate, 0.6-6.2 parts of triisopropanolamine, 1.3-2.2 parts It is composed of sodium α-alkenyl sulfonate, 0.5-1.0 parts of polyvinyl alcohol and 1.4-2.1 parts of anhydrous calcium chloride.

[0055] The technical effect of this embodiment can be directly derived based on the beneficial effect of Embodiment 1, and will not be repeated here.

Embodiment 3

[0057] This embodiment provides a formula for the further preferred component dosage of the repair agent dry mixture described in Embodiment 2, that is: in parts by weight, it consists of 378 to 405 parts of Portland cement, 362 to 394 parts Graded river sand, 210-232 parts of graded gravel, 13.9-15.4 parts of silicon powder, 5.3-6.2 parts of fly ash, 0.5-1.6 parts of calcium formate, 0.3-5.1 parts of triisopropanolamine, 1.5-2.0 parts It is composed of sodium α-alkenyl sulfonate, 0.6-0.9 parts of polyvinyl alcohol and 1.5-1.9 parts of anhydrous calcium chloride.

[0058] The technical effect of this embodiment can be directly derived based on the beneficial effect of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com