Lateral jetting device

A transmission device and locking device technology, applied in printing, typewriters, etc., can solve problems such as inkjet head damage, achieve cost reduction, prevent detachment from guide rails, and maintain a constant distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

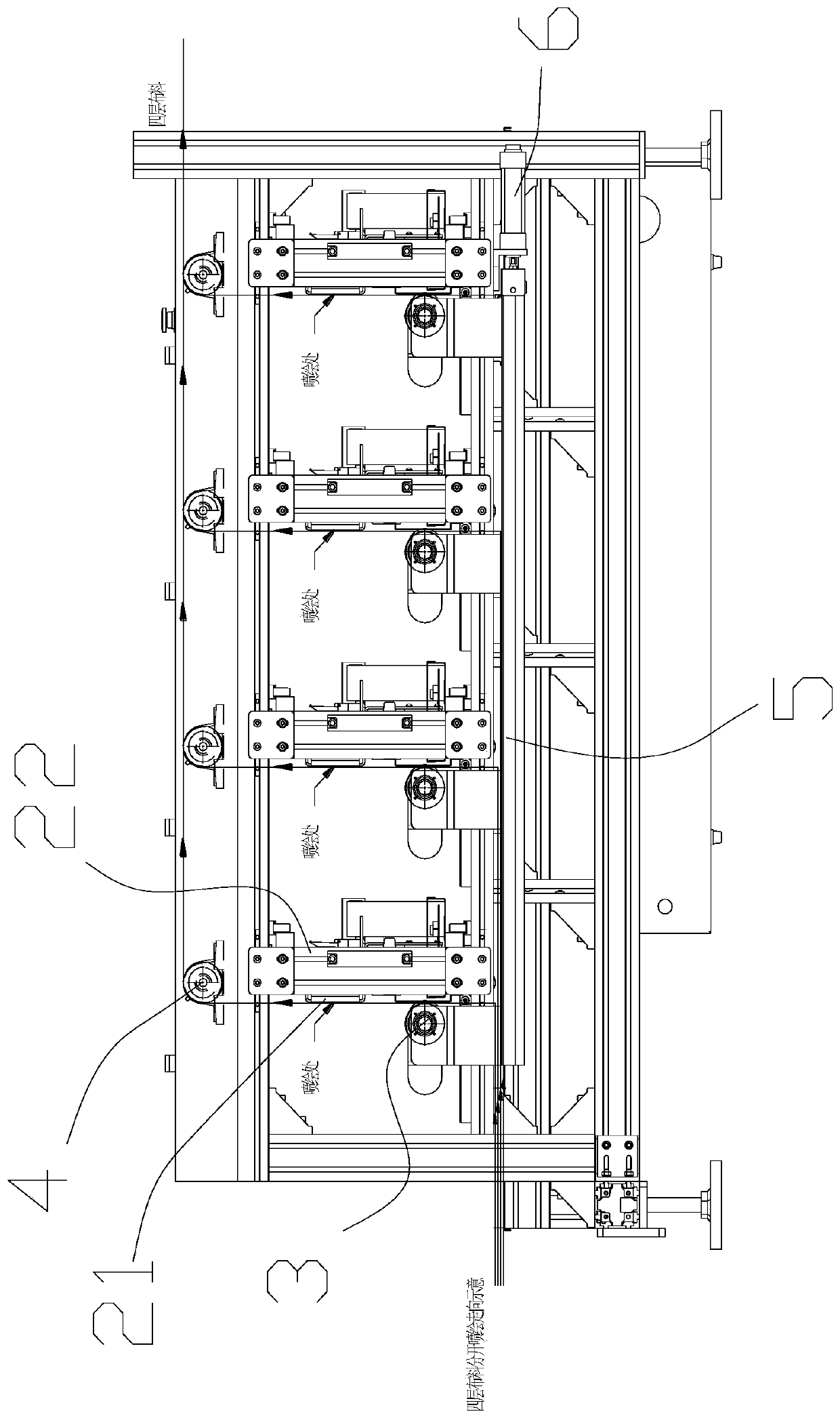

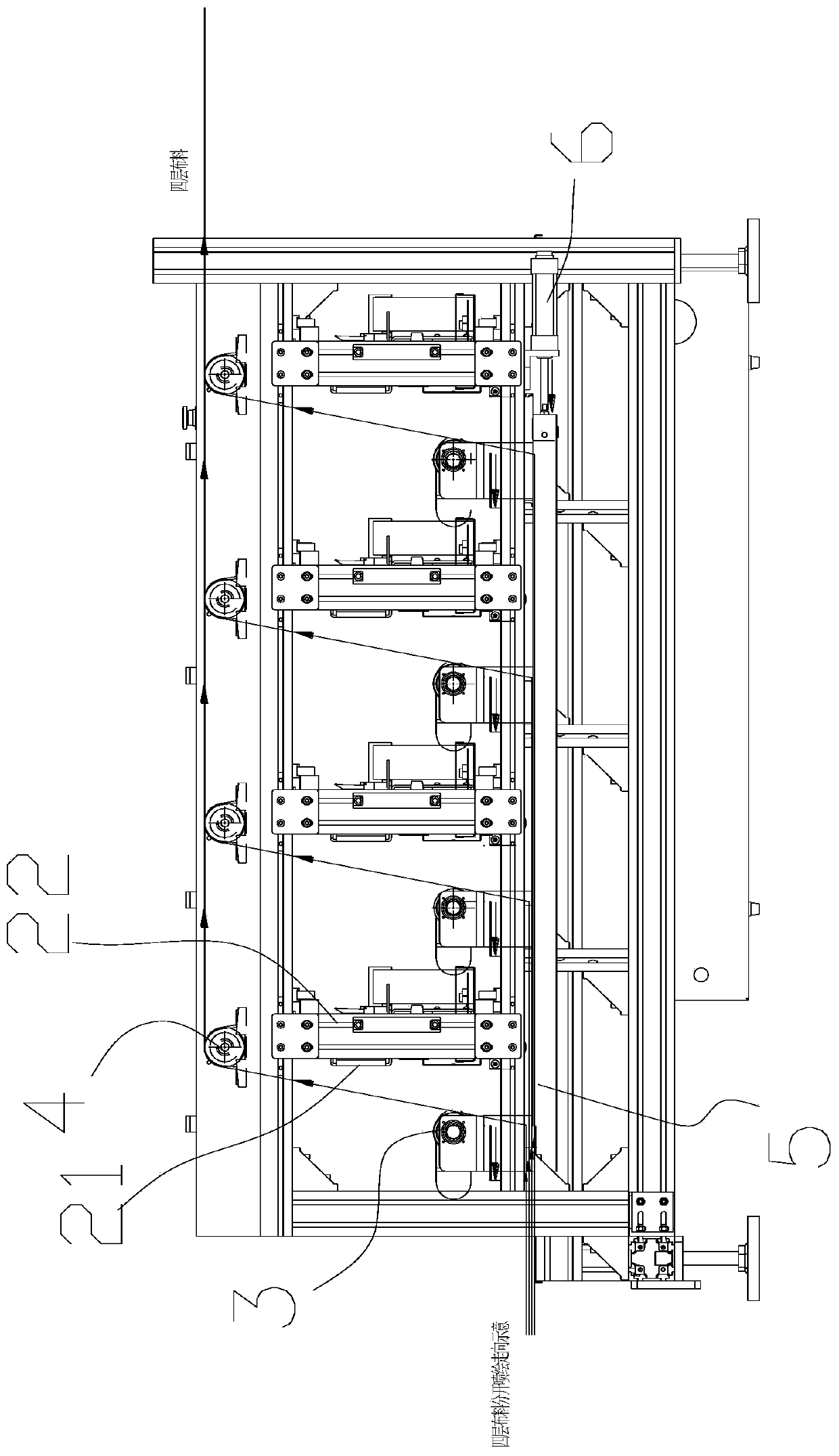

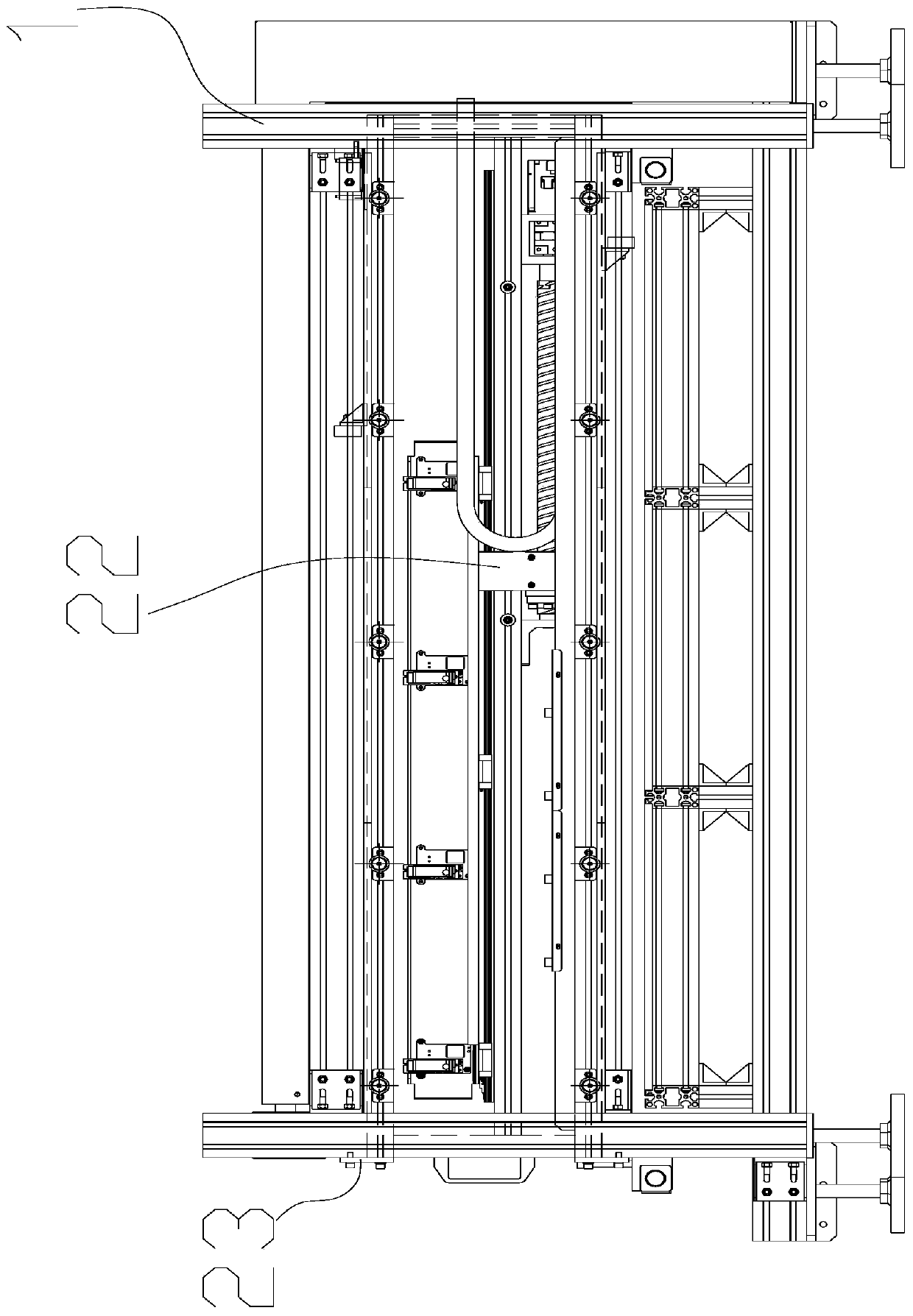

[0033] Such as Figure 1-7 , a kind of side spraying device, comprises frame 1, is provided with several side spraying units 2 on the frame 1, and the number of side spraying units 2 can be set according to actual production demand, and side spraying unit 2 includes along several nozzle assemblies 21 , the spraying direction of the spray head assembly 21 is set along the horizontal direction, and the transmission device for conveying the sheet material is also provided on the frame 1. The transmission device includes a movable roller 3 arranged on one side of the side spray unit 2 correspondingly, and the movable roller 3 It is arranged on the side of the inkjet head close to the nozzle assembly 21, and the sheet material is transported to the vicinity of the inkjet head through the movable roller 3, and the sheet material in the ejected state is arranged in the vertical direction. Lead-in or lead-out power roller 4.

[0034] The side spray unit 2 includes a sliding table 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com