A dry grain decorative ceramic tile with strong three-dimensional effect and its manufacturing method

A manufacturing method and technology for ceramic tiles, applied in the field of ceramic tiles, can solve the problems of inconspicuous three-dimensional effect on the surface of finished ceramic tiles, reducing the dry particle amount of product glaze, damage to nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

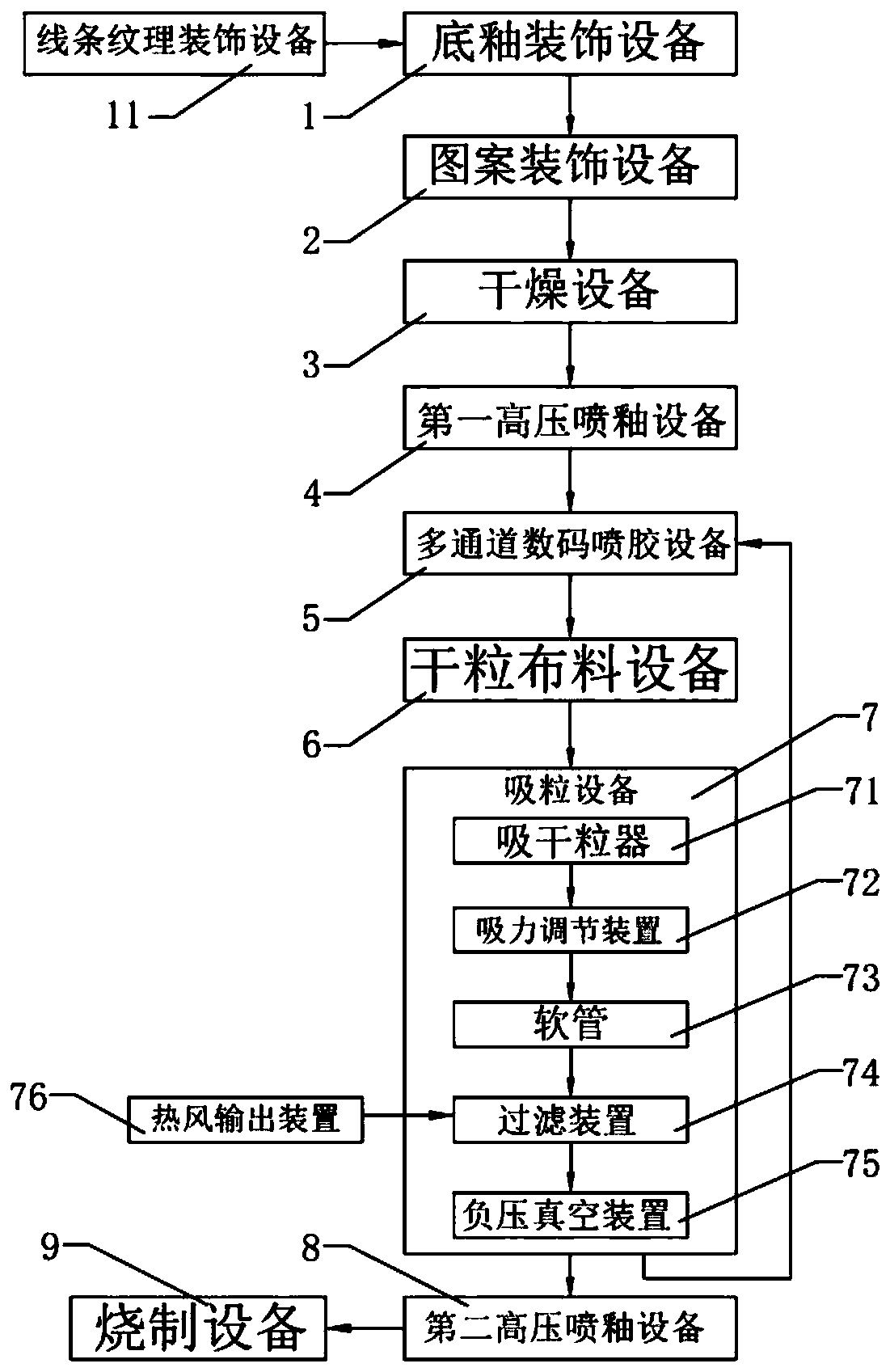

[0079] A method for manufacturing a dry grain decorative ceramic tile with a strong three-dimensional effect, comprising the following steps:

[0080] A. Bottom glaze decoration: Carry out bottom glaze decoration on the surface of the green body;

[0081] B, pattern decoration: control the temperature of the green body after the bottom glaze decoration in step A at 40°C, and then carry out pattern decoration on the bottom glaze surface of the green body;

[0082] C, drying: drying the green body after the pattern decoration in step B;

[0083] D, dry granule decoration: spread dry granule on the body surface after step C drying, carry out dry granule decoration;

[0084] E, spraying protective glaze: spraying protective glaze on the body surface after dry grain decoration in step D;

[0085] F. Firing: firing the body after spraying the protective glaze in step E to obtain a dry grain decorative ceramic tile with a three-dimensional effect.

[0086] Before the step A, the g...

Embodiment 2

[0097] A method for manufacturing a dry grain decorative ceramic tile with a strong three-dimensional effect, comprising the following steps:

[0098] A. Bottom glaze decoration: Carry out bottom glaze decoration on the surface of the green body;

[0099] B. Pattern decoration: control the temperature of the green body after the bottom glaze decoration in step A at 45°C, and then carry out pattern decoration on the bottom glaze surface of the green body;

[0100] C, drying: drying the green body after the pattern decoration in step B;

[0101] D, dry granule decoration: spread dry granule on the body surface after step C drying, carry out dry granule decoration;

[0102] E, spraying protective glaze: spraying protective glaze on the body surface after dry grain decoration in step D;

[0103] F. Firing: firing the body after spraying the protective glaze in step E to obtain a dry grain decorative ceramic tile with a three-dimensional effect.

[0104] Before the step A, the g...

Embodiment 3

[0114] A method for manufacturing a dry grain decorative ceramic tile with a strong three-dimensional effect, comprising the following steps:

[0115] A. Bottom glaze decoration: Carry out bottom glaze decoration on the surface of the green body;

[0116] B. Pattern decoration: control the temperature of the green body after the bottom glaze decoration in step A to 50°C, and then carry out pattern decoration on the bottom glaze surface of the green body;

[0117] C, drying: drying the green body after the pattern decoration in step B;

[0118] D, dry granule decoration: spread dry granule on the body surface after step C drying, carry out dry granule decoration;

[0119] E, spraying protective glaze: spraying protective glaze on the body surface after dry grain decoration in step D;

[0120] F. Firing: firing the body after spraying the protective glaze in step E to obtain a dry grain decorative ceramic tile with a three-dimensional effect.

[0121] Before the step A, the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com