Calibration device and method for laser displacement measurement system

A measurement system and laser displacement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of increased calibration time, failure to reflect the real status of the stiffness measuring instrument, equipment damage, etc., and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail through specific embodiments below.

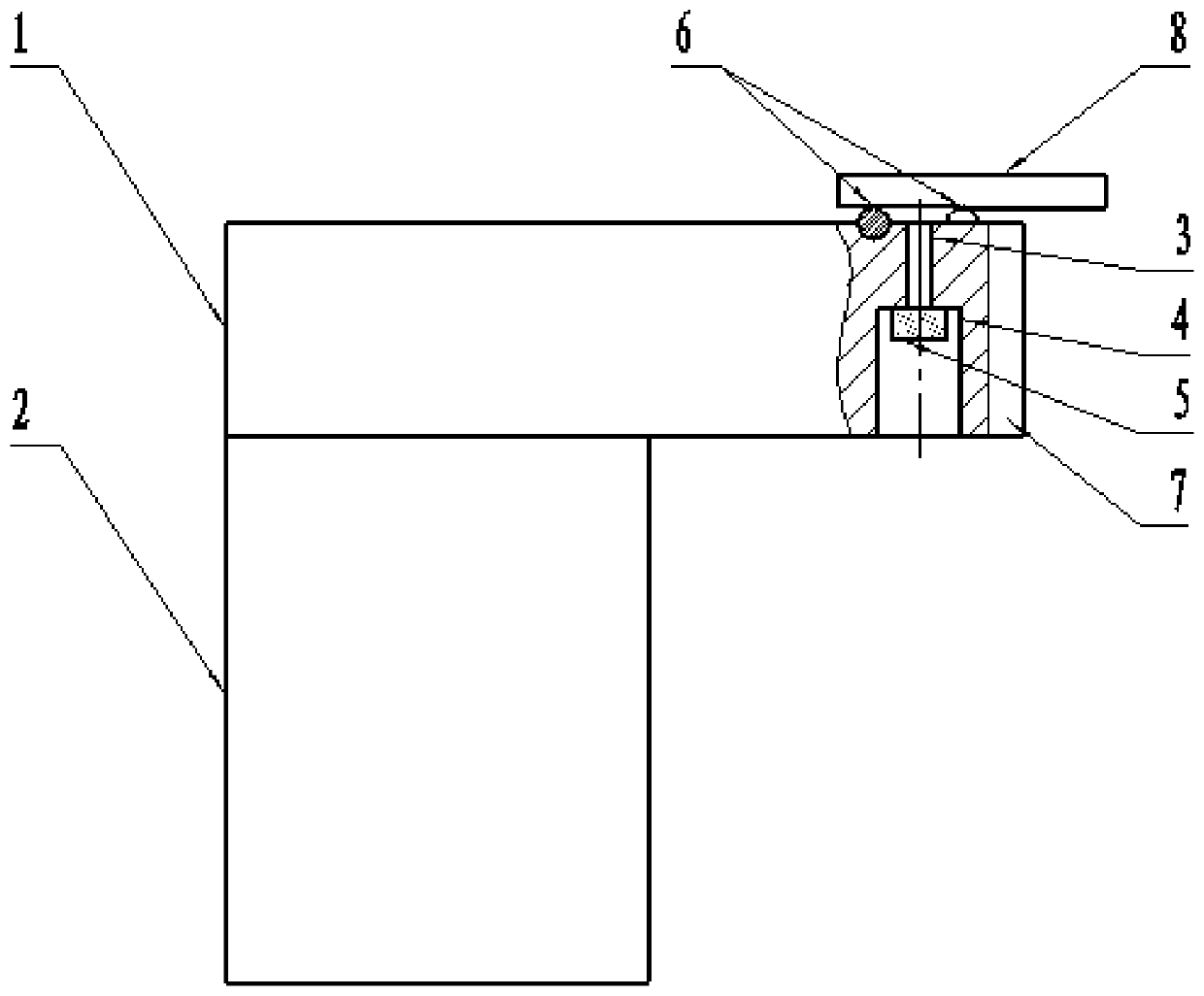

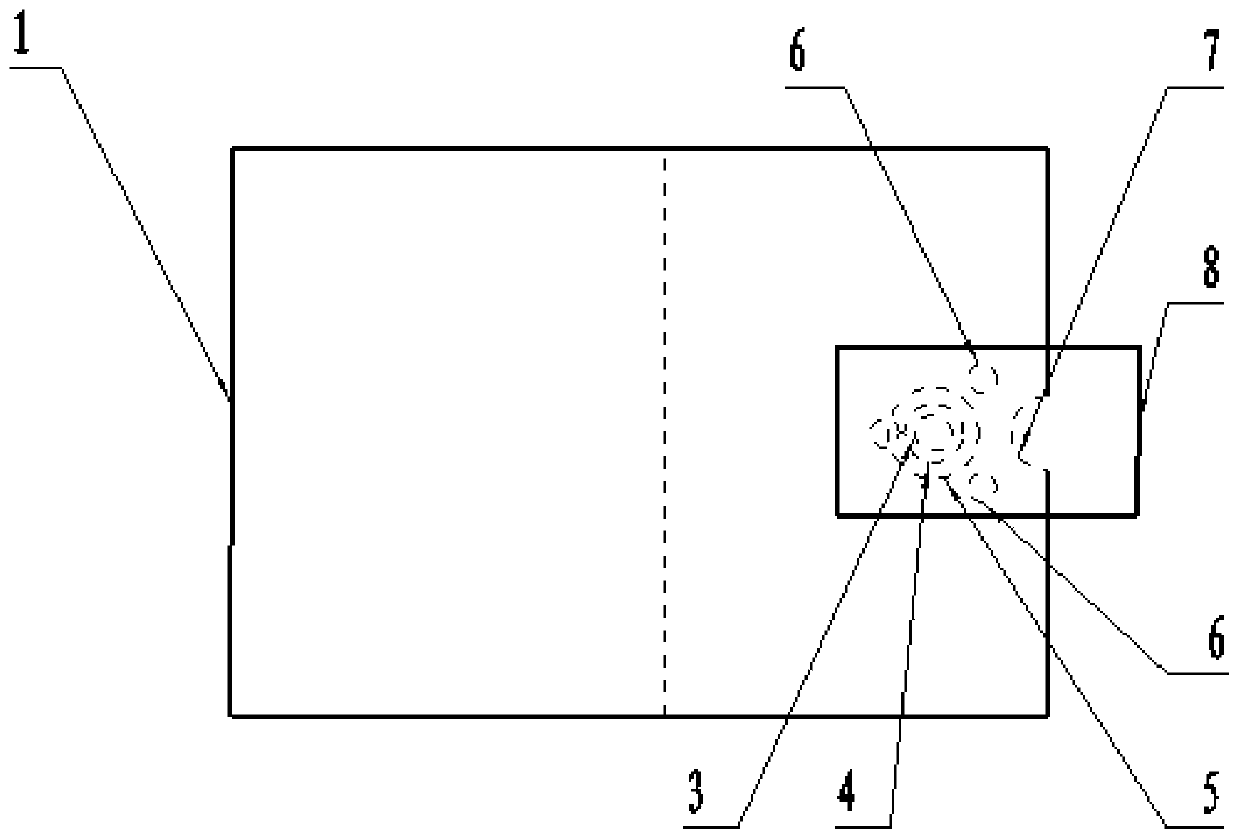

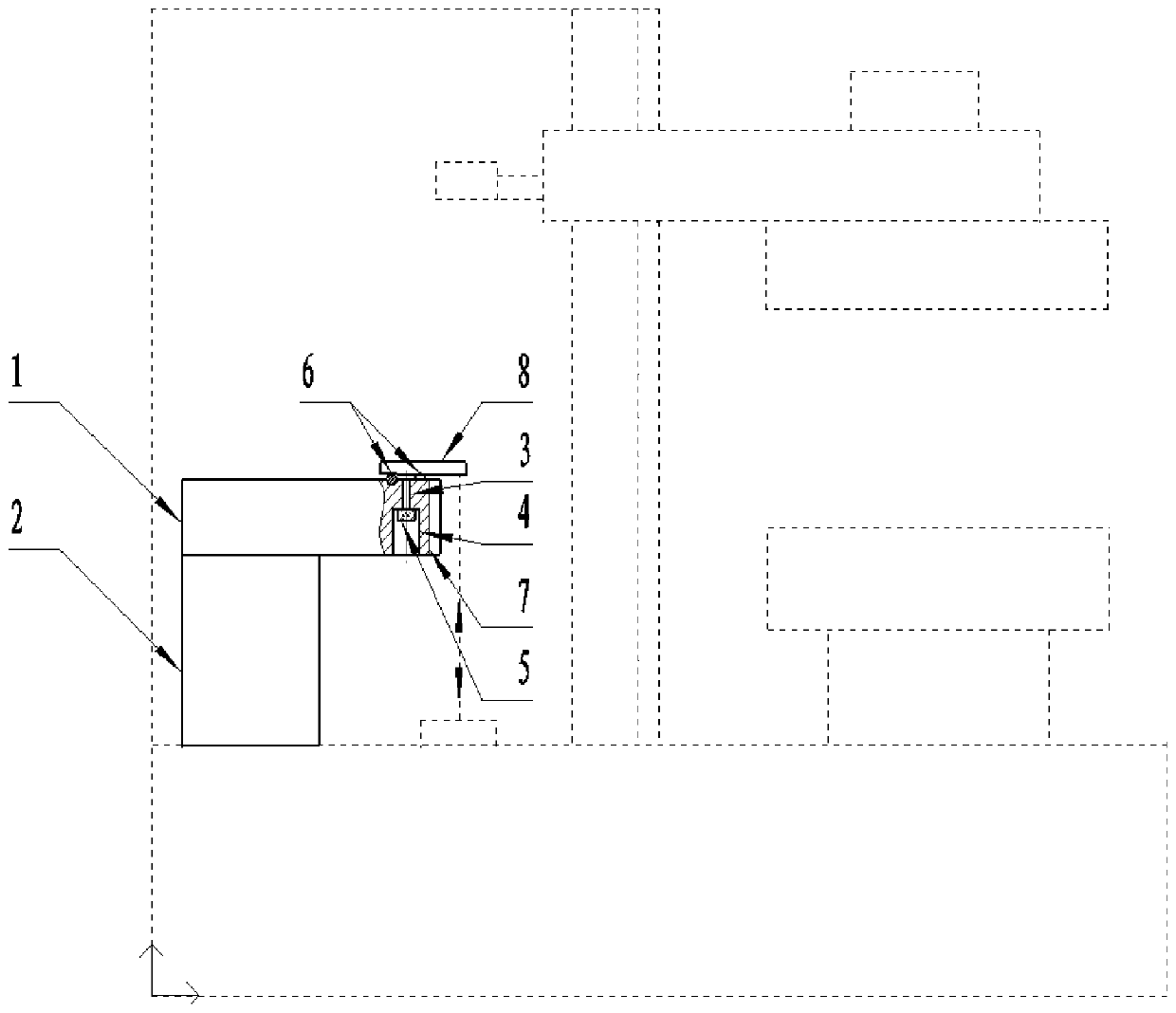

[0024] A laser displacement measurement system calibration device, used to calibrate the laser displacement measurement system on a high-precision stiffness measuring instrument, it includes a workbench, and the workbench includes cuboid one (1), cuboid two (2), cuboid one The length of (1) is greater than the length of cuboid two (2), and the lower surface of cuboid one (1) fits with the upper surface of cuboid two (2); The left side of cuboid two (2) and cuboid one (1) The left sides are flush, and cuboid one (1) and cuboid two (2) form an inverted L-shaped structure as a whole; the gauge block group includes five gauge blocks (8) with different thicknesses, and the thickness of the gauge blocks (8) ranges from small to In large increments, the size difference between the thinnest and thickest gauge blocks (8) just covers the working range of the laser displacement measurem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com