Wind power equipment with circumferential fixed structures

A circumferentially fixed, wind power equipment technology, applied in wind power generation, mechanical equipment, wind turbine combination and other directions, can solve the problems of local shaft overheating, impact, damage to connecting bolts, etc., to extend service life, improve economic benefits, improve use effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

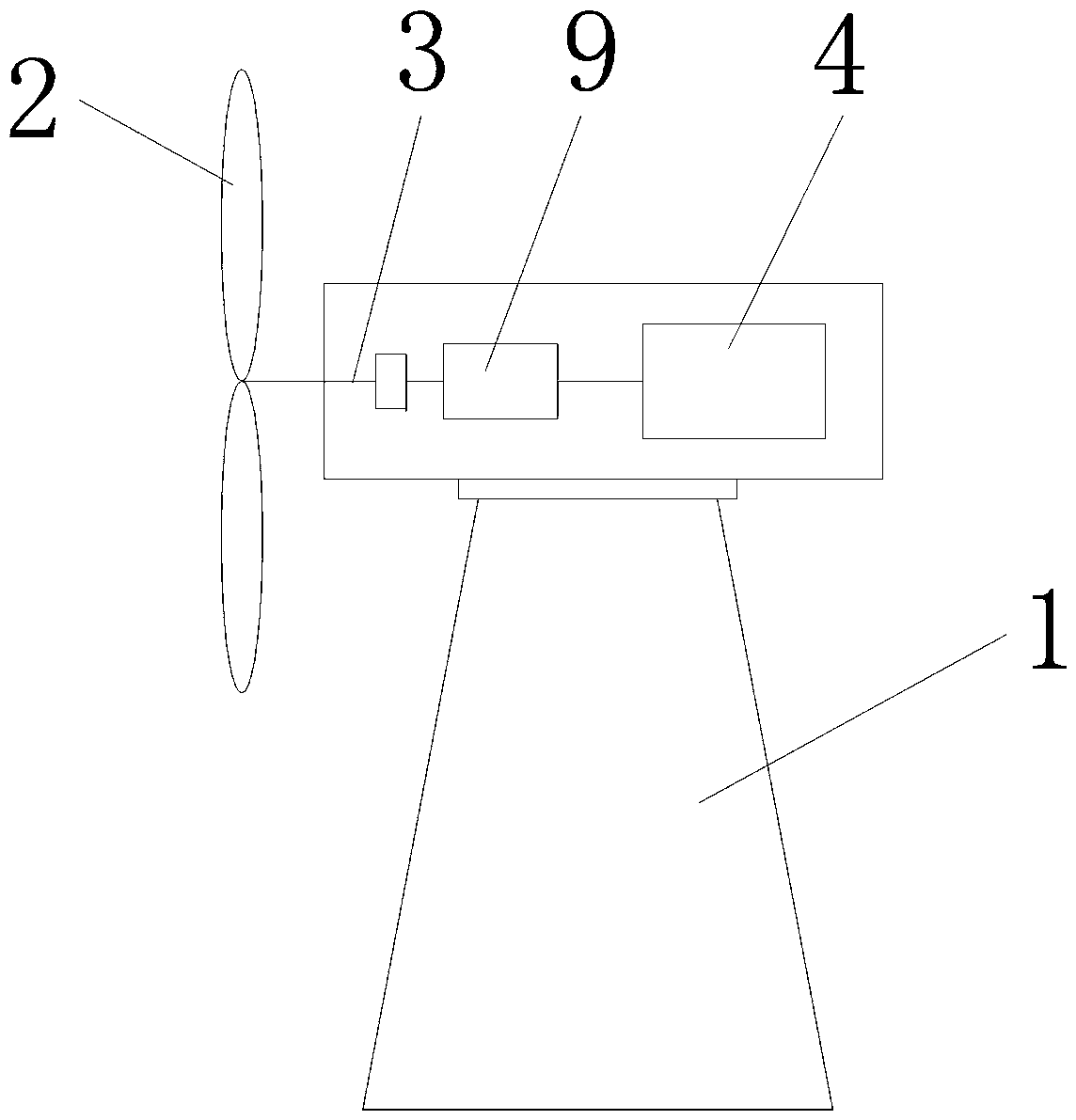

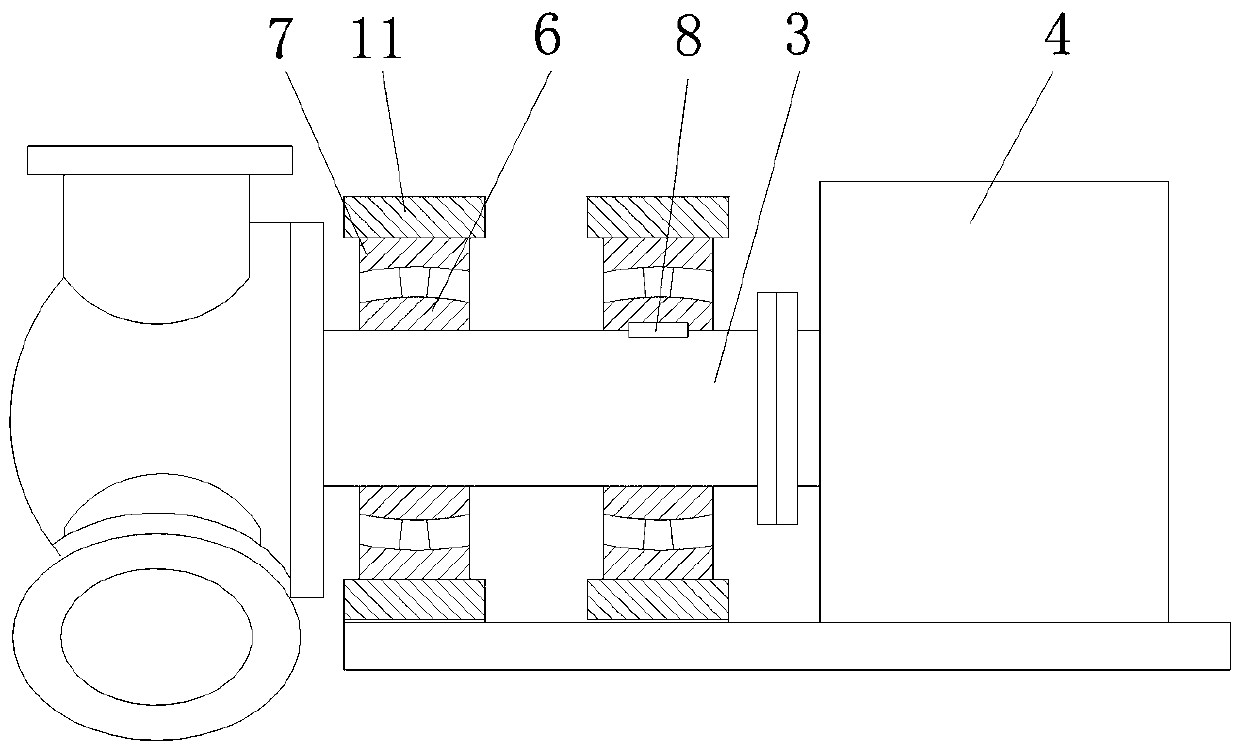

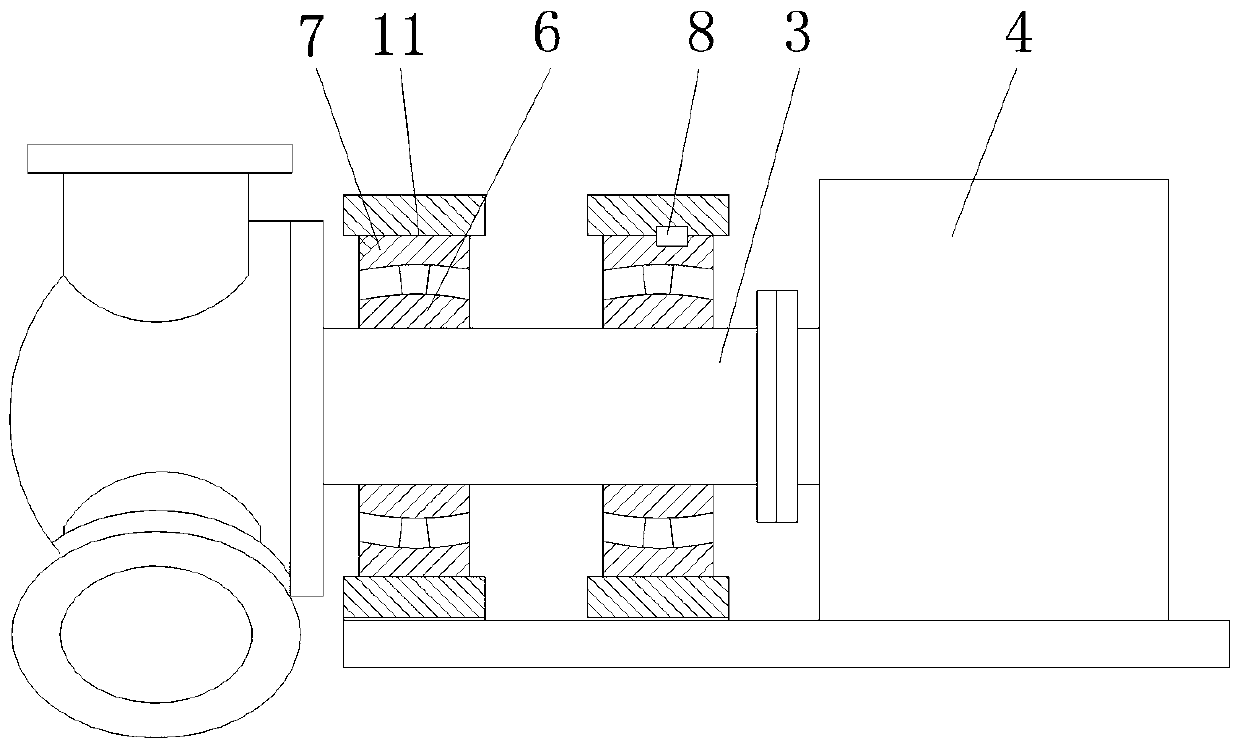

[0059] see Figure 2-4 , a (direct drive) wind power equipment without a gearbox, including a main shaft 3, a bearing 5 is arranged on the main shaft 3, the outer ring 7 of the bearing 5 is fixed to the bearing chamber in the circumferential direction, and the inner ring 6 of the bearing 5 is fixed to the main shaft 3 in the circumferential direction Fixed, wherein at least one of the outer ring 7 and the inner ring 6 is fixed circumferentially, so as to avoid the phenomenon of the bearing 5 running around due to vibration.

Embodiment 2

[0061] see Figure 5-Figure 8 , a wind power equipment with a gear box 9, including a gear box 9, a transmission shaft 10 in the gear box 9 and a bearing 5, at least one of the bearing 5 and the bearing chamber 11 outside the bearing 5 is provided with a circumferential fixed structure 8 .

Embodiment 3

[0063] see Figure 5-Figure 8 , a wind power equipment with a gearbox 9, including a gearbox 9, two transmission shafts 10 in the gearbox 9 and bearings 5, at least one of the bearings 5 and the bearing chamber 11 outside the bearing 5 is provided with a circumferential fixing structure 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com