Vibration isolator for track floating slab

A floating plate and vibration isolator technology, applied in tracks, roads, buildings, etc., can solve the problems affecting damping performance, anti-corrosion and waterproof performance, small adjustment range, leakage of damping agent, etc., and achieve good anti-corrosion and anti-aging functions, Simple and compact structure, the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

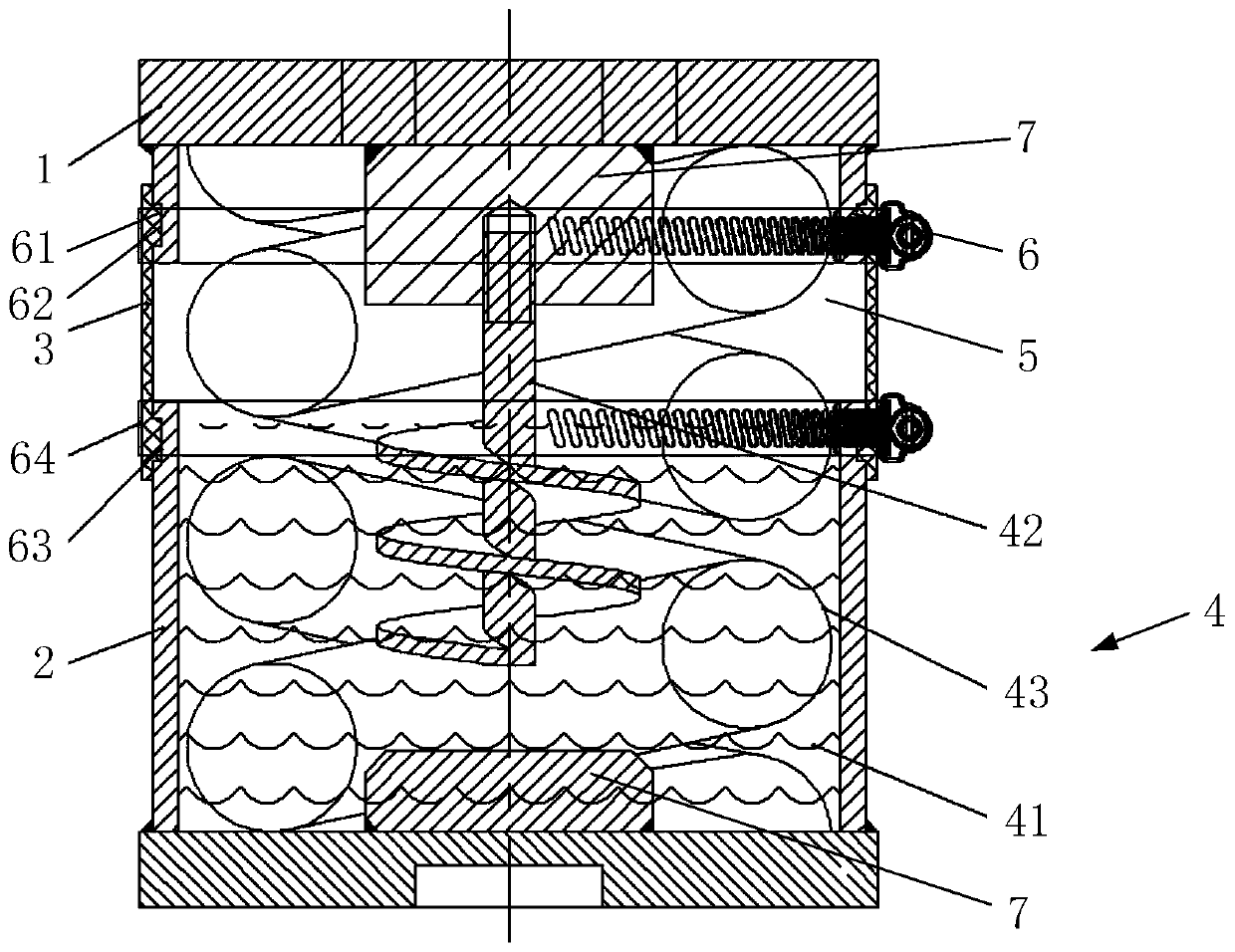

[0022] Such as figure 1 As shown, the vibration isolator for the track floating plate in this embodiment includes an upper cover plate 1 , a bottom plate 2 , a telescopic sleeve 3 and a vibration isolation assembly 4 . Wherein, the telescopic sleeve 3 is connected between the upper cover plate 1 and the bottom plate 2 to form a sealed chamber 5, and its structure is simple and compact. At the same time, the setting of the sealed chamber 5 effectively isolates the vibration isolation component 4 from the external air and water, has good anti-corrosion and anti-aging functions, makes each component reusable, and has low maintenance costs; and the vibration isolator has excellent waterproof sealing As a result, the damping agent 41 is prevented from leaking when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com