Preparation method of magnesium and magnesium alloy with silane/sodium hyaluronate composite coating on surface

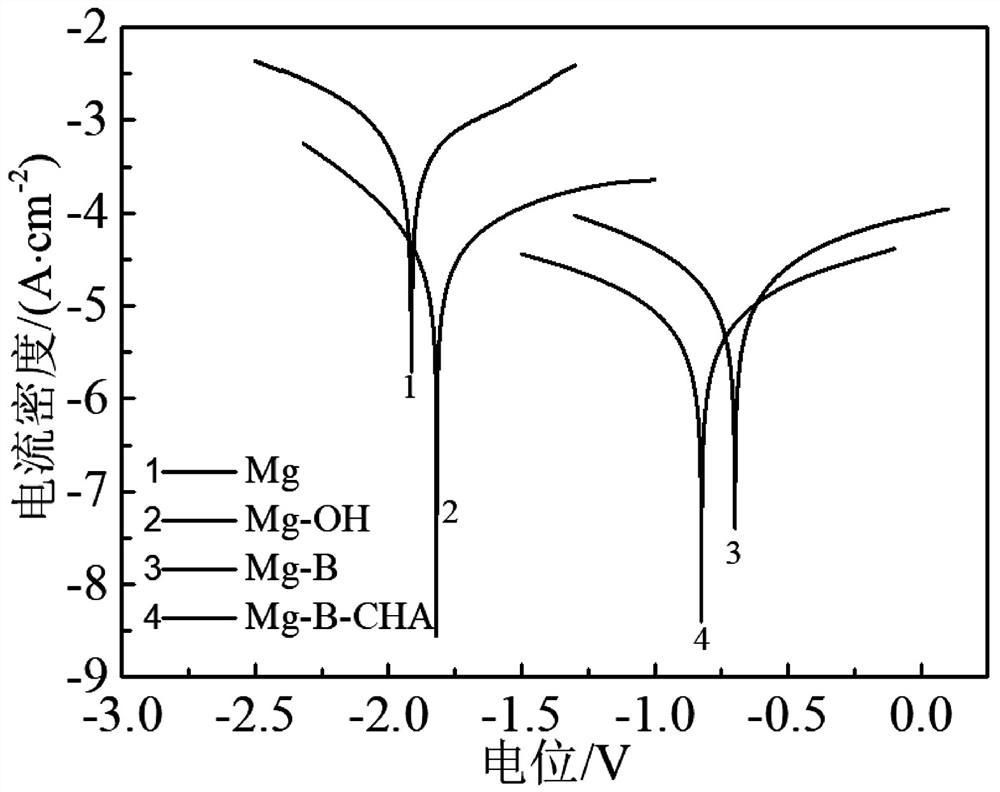

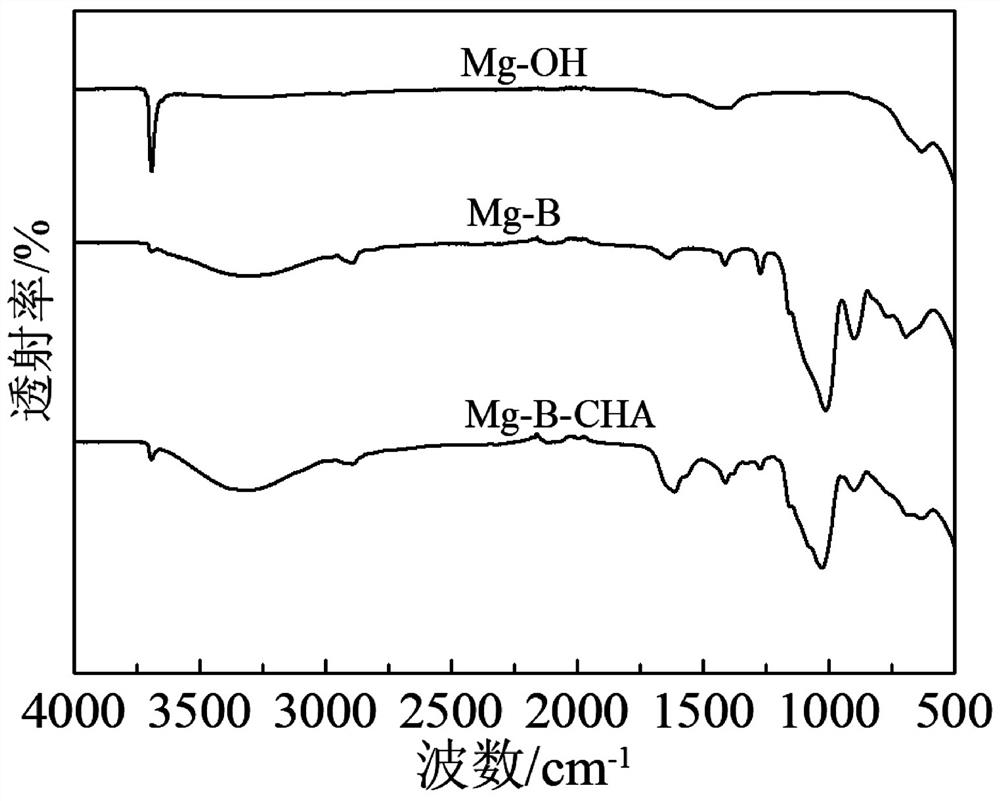

A technology of sodium hyaluronate and composite coating, which is applied in coatings, metal material coating processes, etc., can solve the problems of hyaluronidase and free radical sensitivity, poor stability of sodium hyaluronate, and lack of mechanical strength. Achieve good biocompatibility and corrosion resistance, low processing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

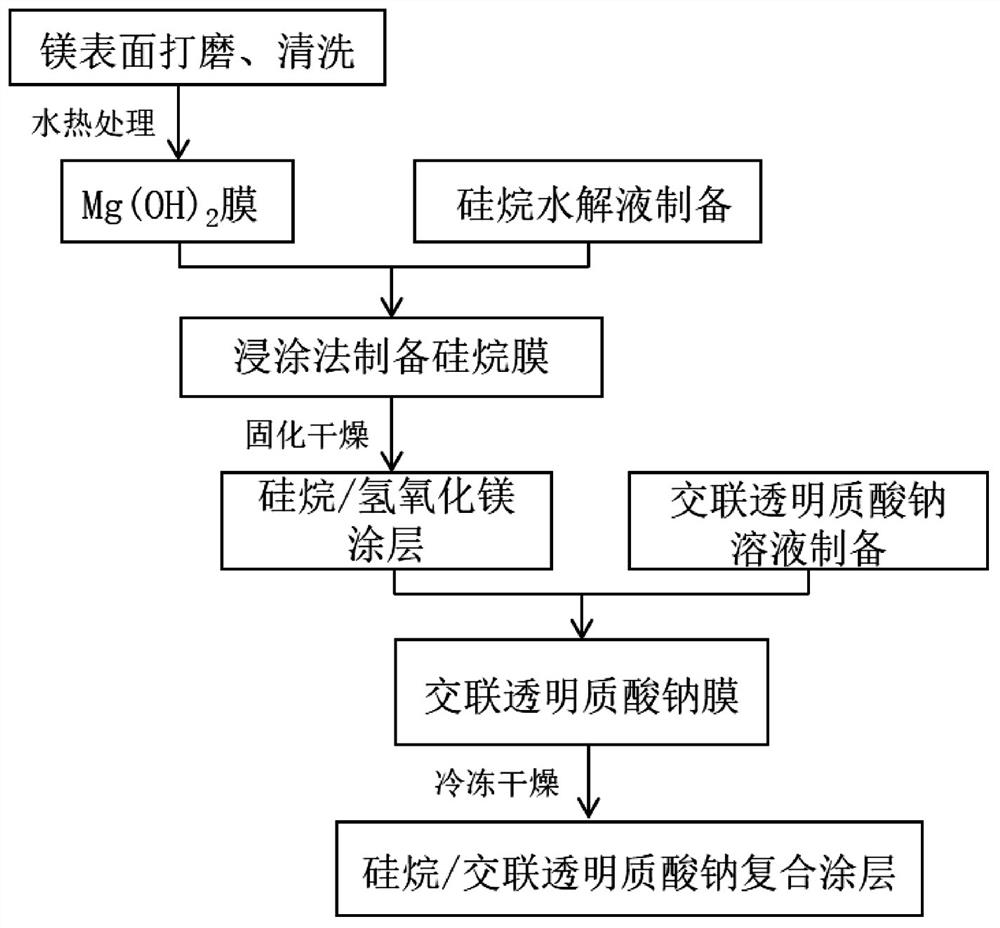

Method used

Image

Examples

Embodiment 1

[0049] Get pure magnesium metal material to prepare multifunctional coating according to the inventive method:

[0050] A. Mechanical decontamination and cleaning:

[0051] After sanding to 1200#, clean the pure magnesium, and ultrasonically clean it in absolute ethanol for 20 minutes at room temperature;

[0052] B. Hydrothermal treatment:

[0053] The cleaned above-mentioned pure magnesium metal material is placed in a reaction kettle of 120°C, pH=12, and 50% full of NaOH solution for 4 hours; air-cooled to room temperature;

[0054] C. Cleaning:

[0055] The pure magnesium metal material after hydrothermal treatment is ultrasonically cleaned in absolute ethanol for 10 minutes, and dried;

[0056] D. Silanization treatment:

[0057] The configuration method of placing the pure magnesium metal material cleaned in step C into the silane ethanol solution: 7 parts by volume of silane in 100 parts by volume of silane ethanol solution, 8 parts by volume of deionized water, and...

Embodiment 2

[0065] Except that the pure magnesium in step A is replaced by ZM61-Ca0.5 of Mg-Ca alloy, other steps are the same as in Example 1, and a magnesium alloy material with a silane / sodium hyaluronate composite coating on the surface can be obtained.

Embodiment 3

[0067] Except that 120°C in step B was changed to 100°C, and 4h was changed to 6h, the rest of the steps were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com