Cement flue gas desulfurizer and its application

A technology of desulfurization agent and desulfurization auxiliary agent, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., to achieve the effects of increasing output, improving grinding conditions, and good grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

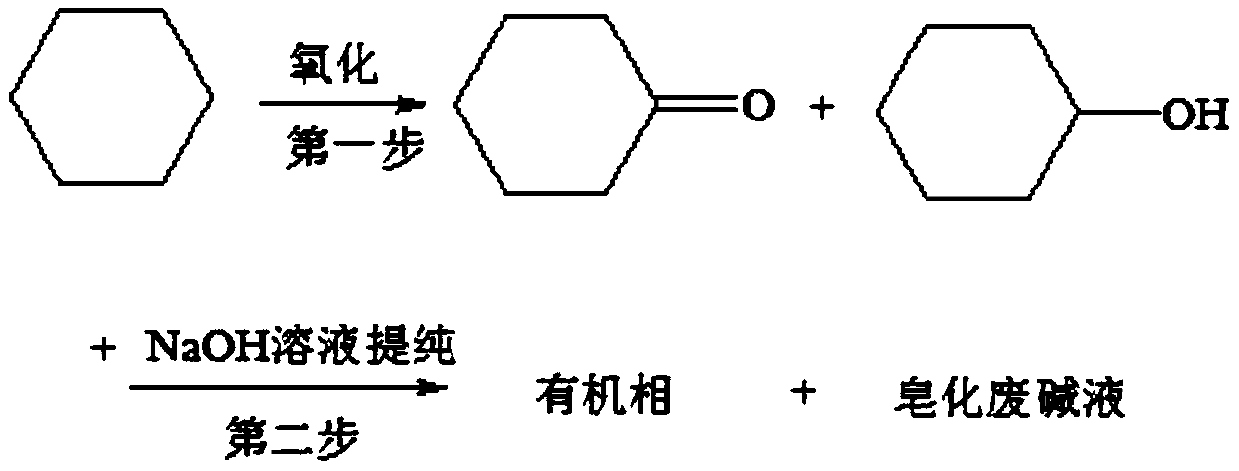

Method used

Image

Examples

Embodiment SA1

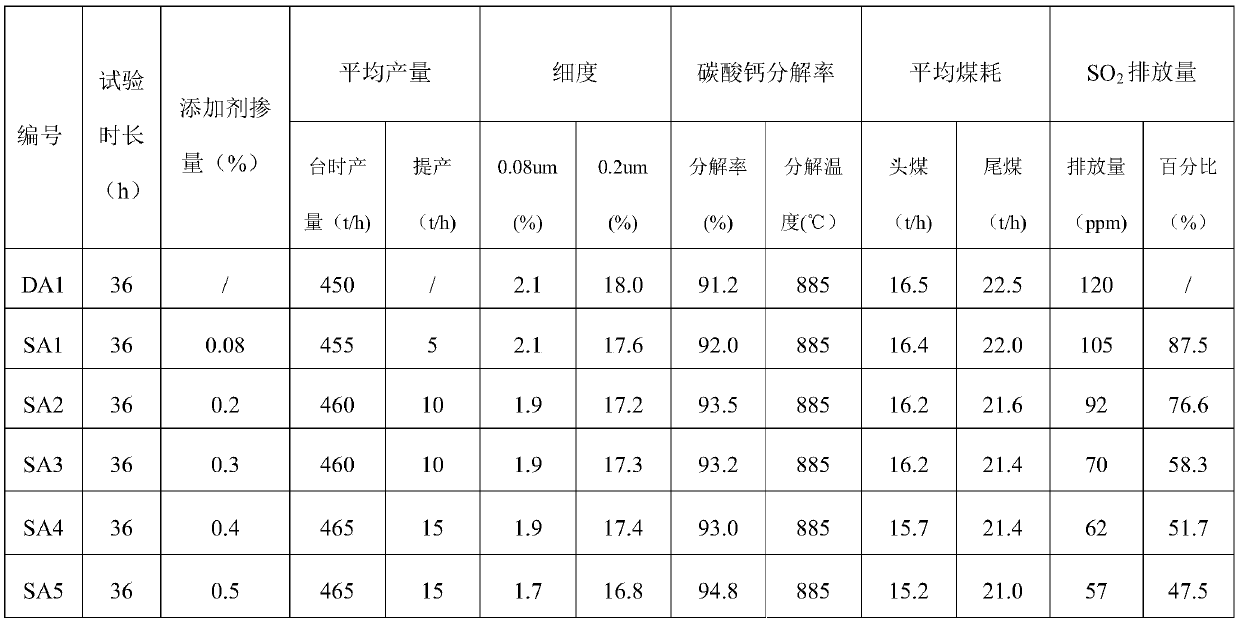

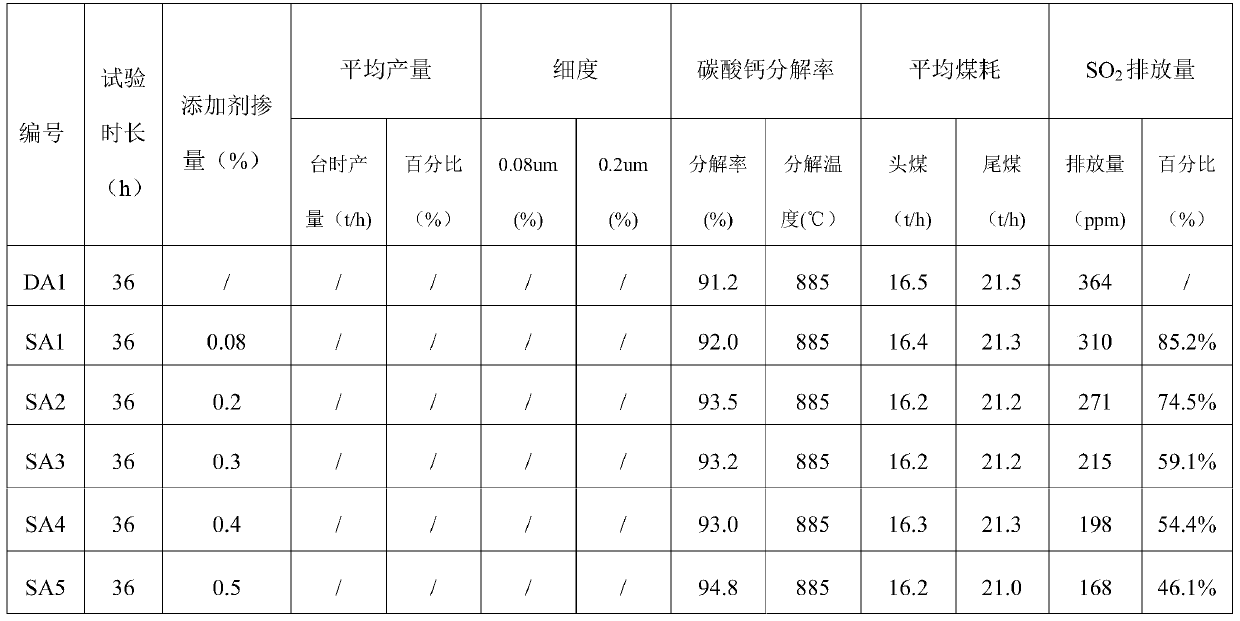

[0059] Liquid A (100 parts by weight) was mixed with raw meal to be ground with cement at a ratio of 0.08% by weight for raw meal grinding and calcination. The specific conditions and results are shown in Table 1 and Table 2.

Embodiment SA2

[0061] Liquid A (100 parts by weight) was mixed with raw meal to be ground with cement at a ratio of 0.2% by weight for raw meal grinding and calcination. The specific conditions and results are shown in Table 1 and Table 2.

Embodiment SA3

[0063] Add liquid A (100 parts by weight) to 20 parts by weight of sodium hydroxide as a cement flue gas desulfurizer, and mix cement with raw meal to be ground in a proportion of 0.3% by weight for raw meal grinding and calcination. For specific conditions and results, see Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com