Novel spherical bulk food discharging structure

A bulk food and spherical technology, applied in the field of new spherical bulk food cutting structure, can solve the problems of uneven filling, hygiene and safety, inapplicability of bulk food, and high labor costs, so as to improve sales efficiency, reduce labor operation and maintenance costs, The effect of uniform blanking amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

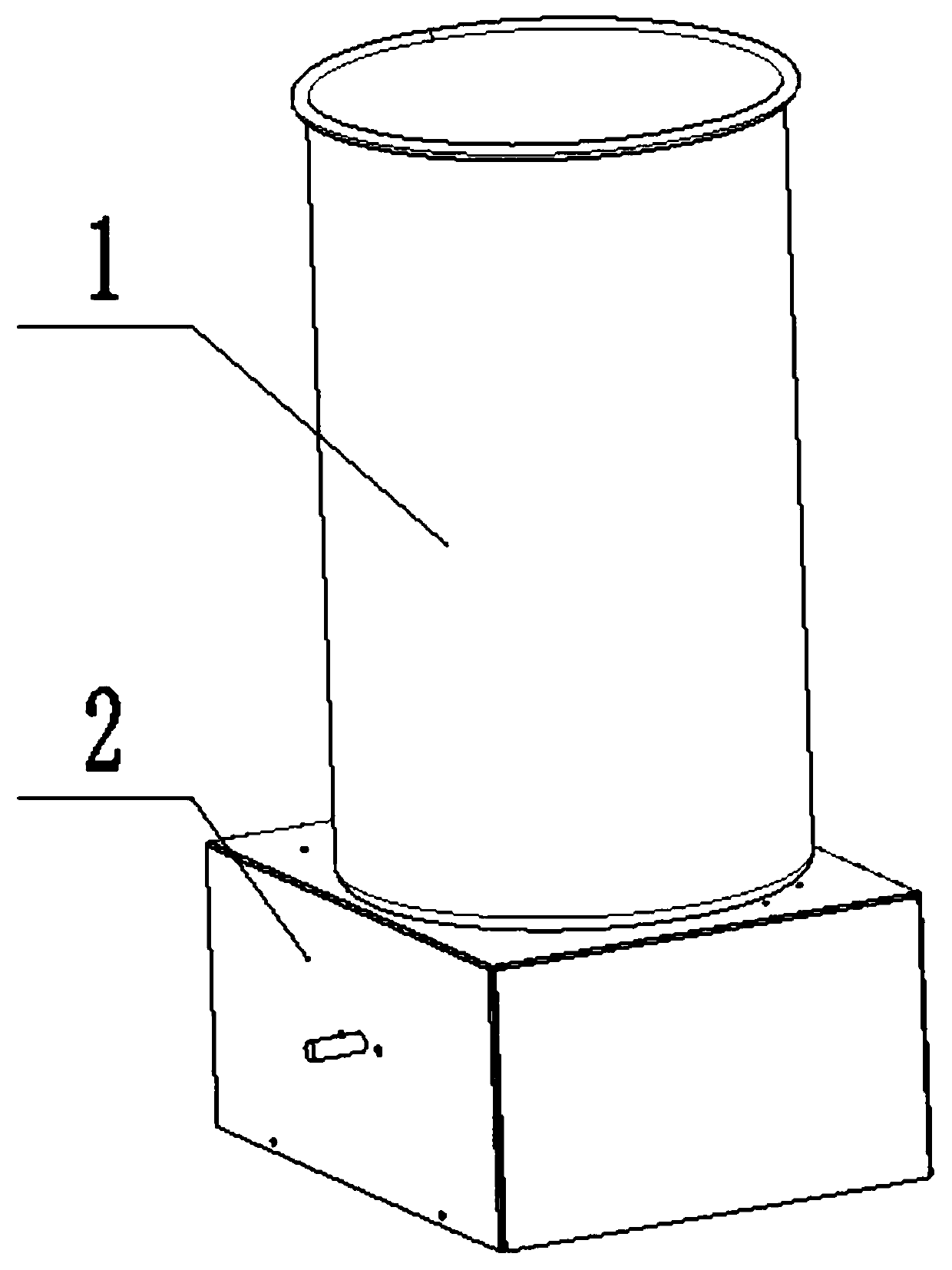

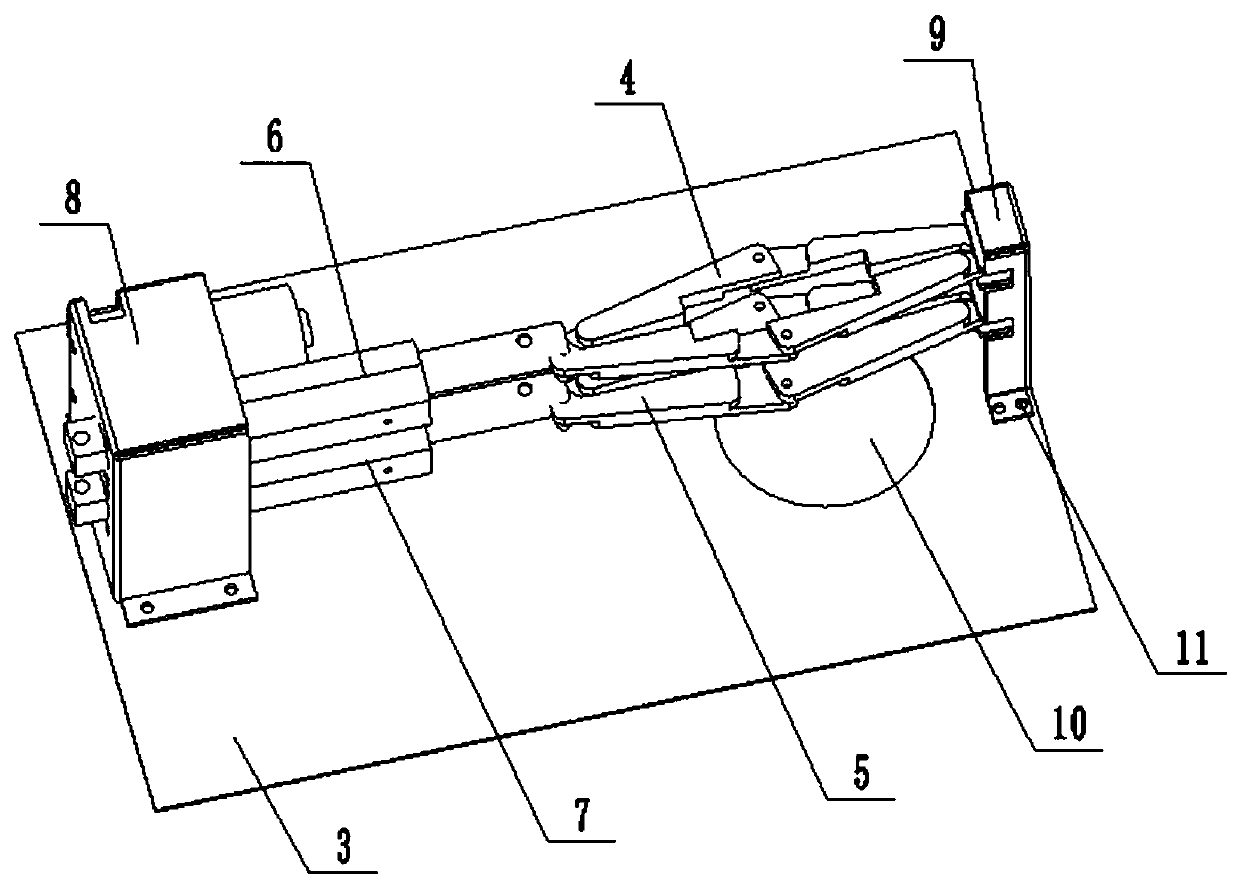

[0017] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a novel spherical bulk food feeding structure of the present invention includes a silo device 1 and a silo support device 2, the silo device 1 is arranged on the upper side of the silo support device 2, and the silo device 1 A stirring device is provided, and the stirring device prevents the bulk food from agglomerating into blocks, and helps to unload the material smoothly. 2. An oscillating device and a telescopic clamp device are installed inside;

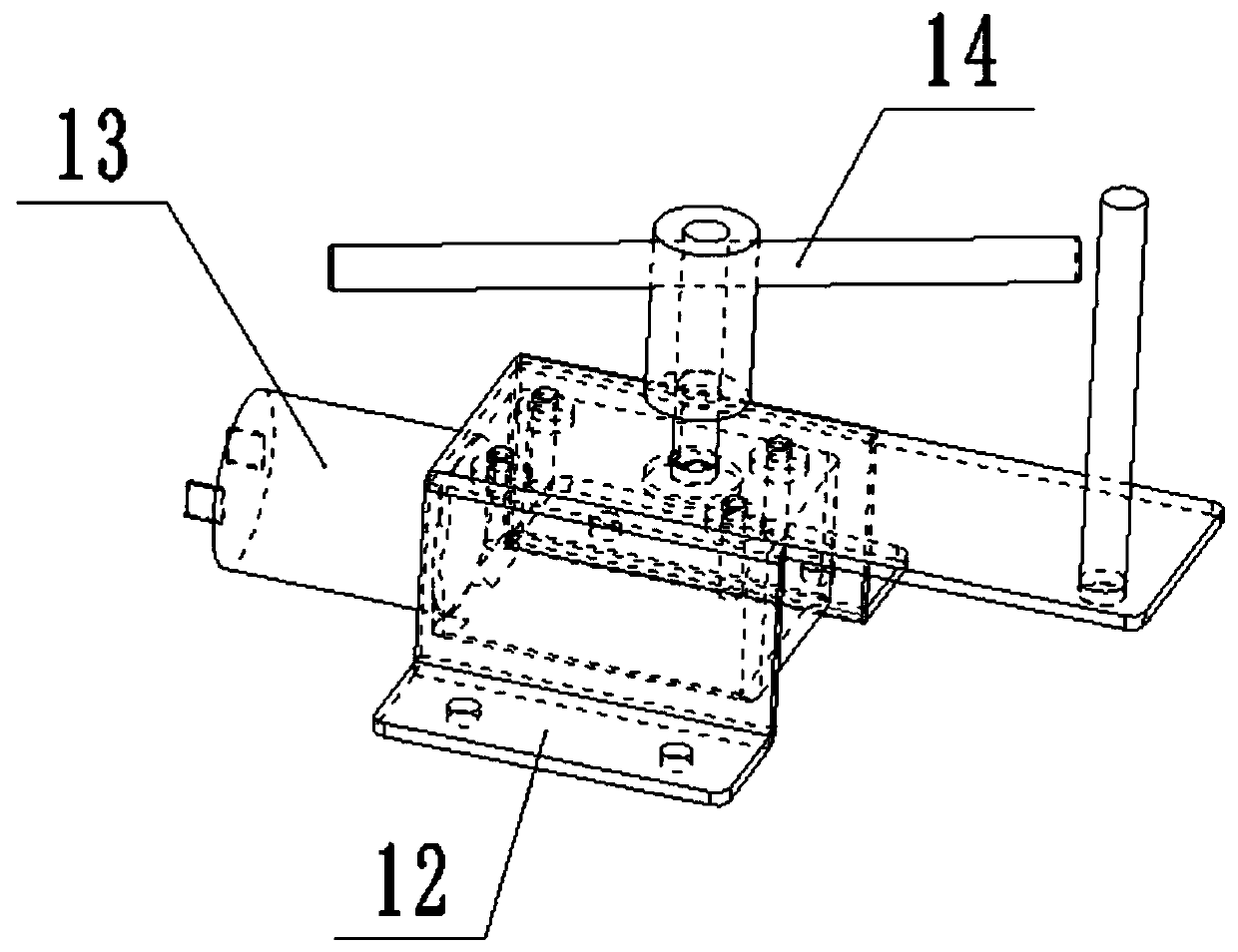

[0018] The structure of the telescopic clamp device is as follows: comprising a support plate 3, an upper quadrilateral hinge 4, a lower quadrilateral hinge 5, an upper drive device 6 and a lower drive device 7, and one end of the support plate 3 is fixed with a drive device fixing plate 8, so The driving device fixing plate 8 is provided with an upper layer driving device 6 and a lower layer driving device 7, and the upper layer driving device 6 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com