Closing-up ribbon, tightening device for tightening closing-up ribbon and ribbon kit with tightening device

A belt body and installation part technology, applied in packaging, transportation and packaging, flexible and slender components, etc., can solve the problems of time-consuming and laborious, dust leakage, and the cloth bag cannot be in close contact with the discharge port, and achieve the effect of avoiding dust leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

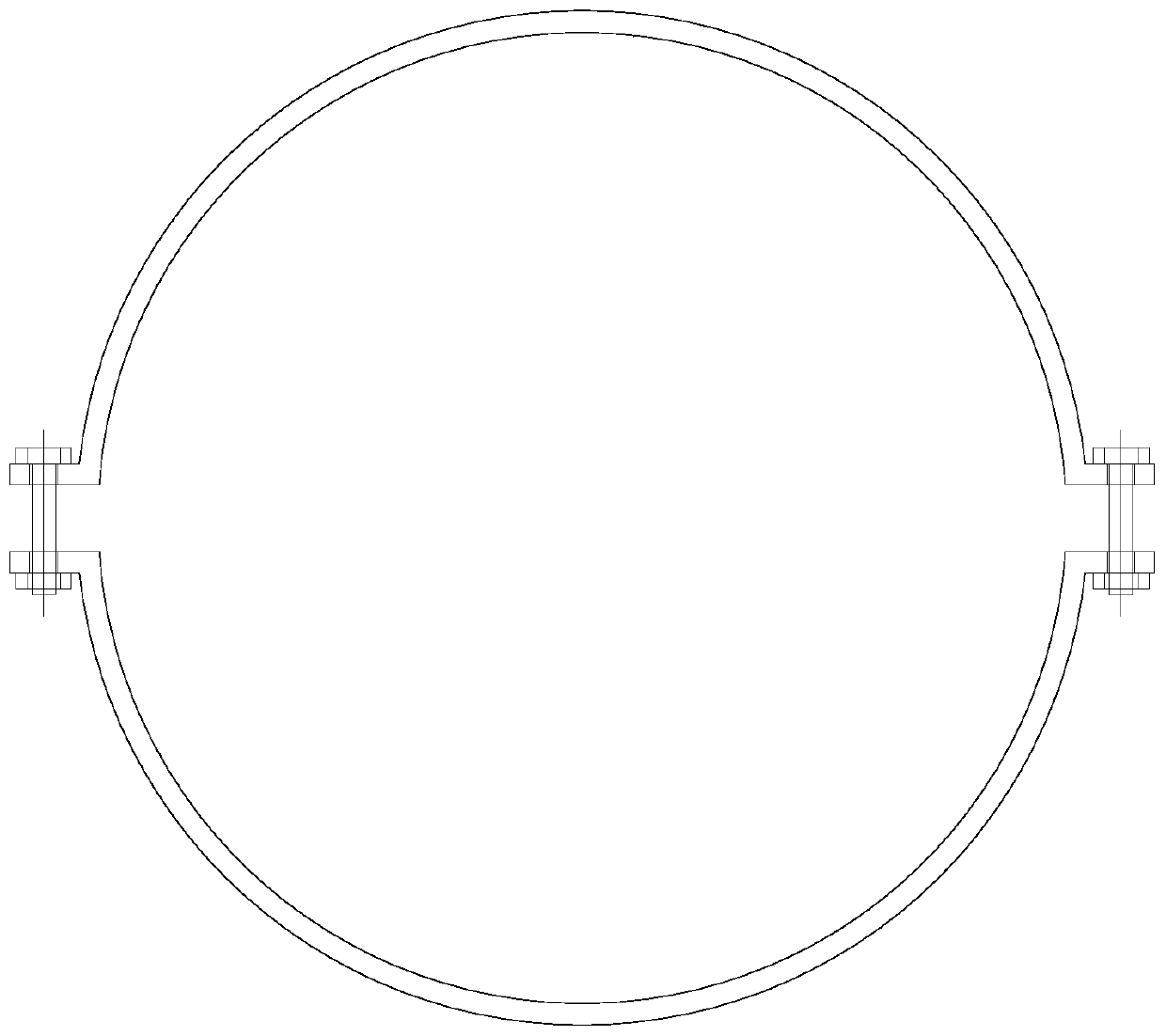

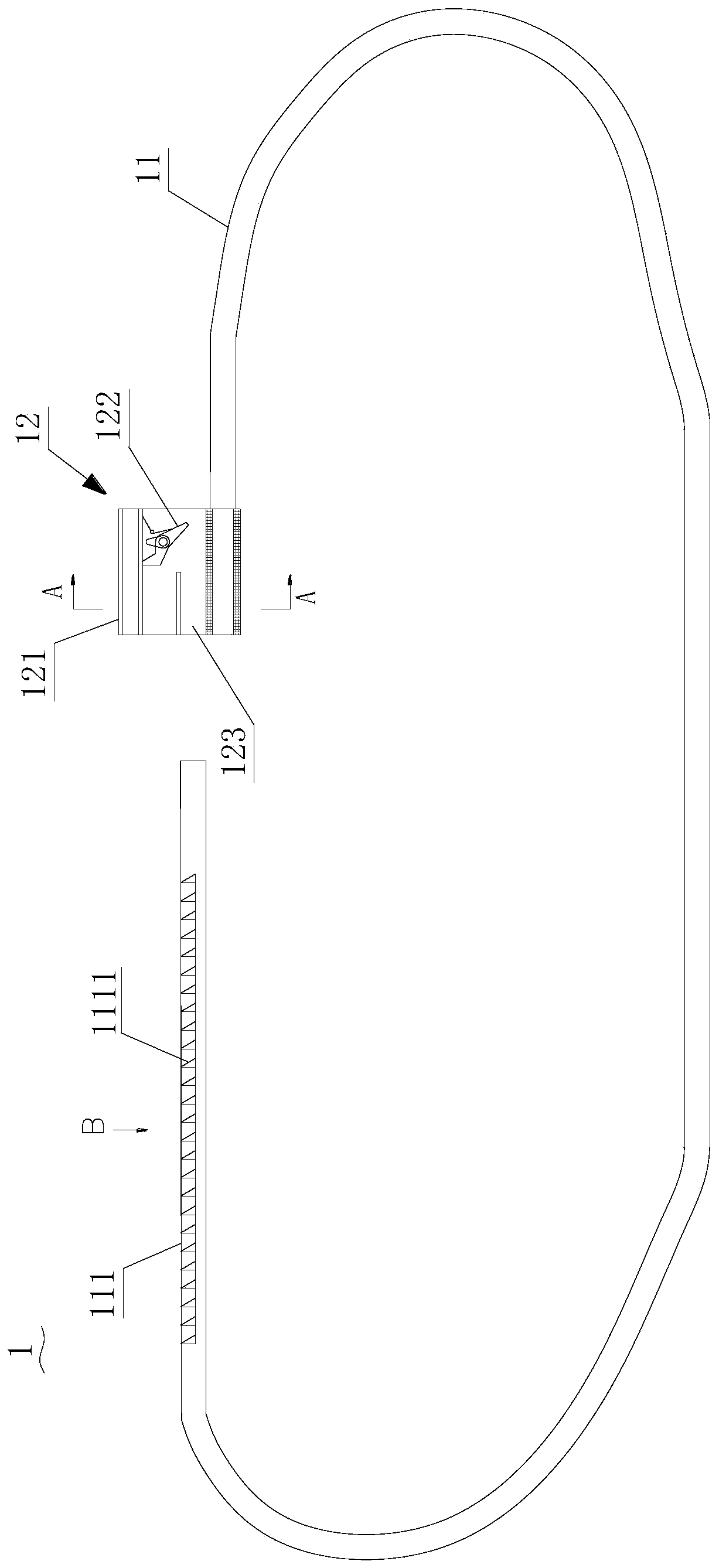

[0045] like Figure 2-Figure 6 As shown, the closing cable tie 1 provided in this embodiment includes a belt body 11 and a lock head 12 .

[0046] The belt body 11 is a strip-shaped belt structure, and one end of the belt body 11 is provided with a tooth region 111 extending along the length direction of the belt body 11 ; the belt body 11 can be made of plastic material.

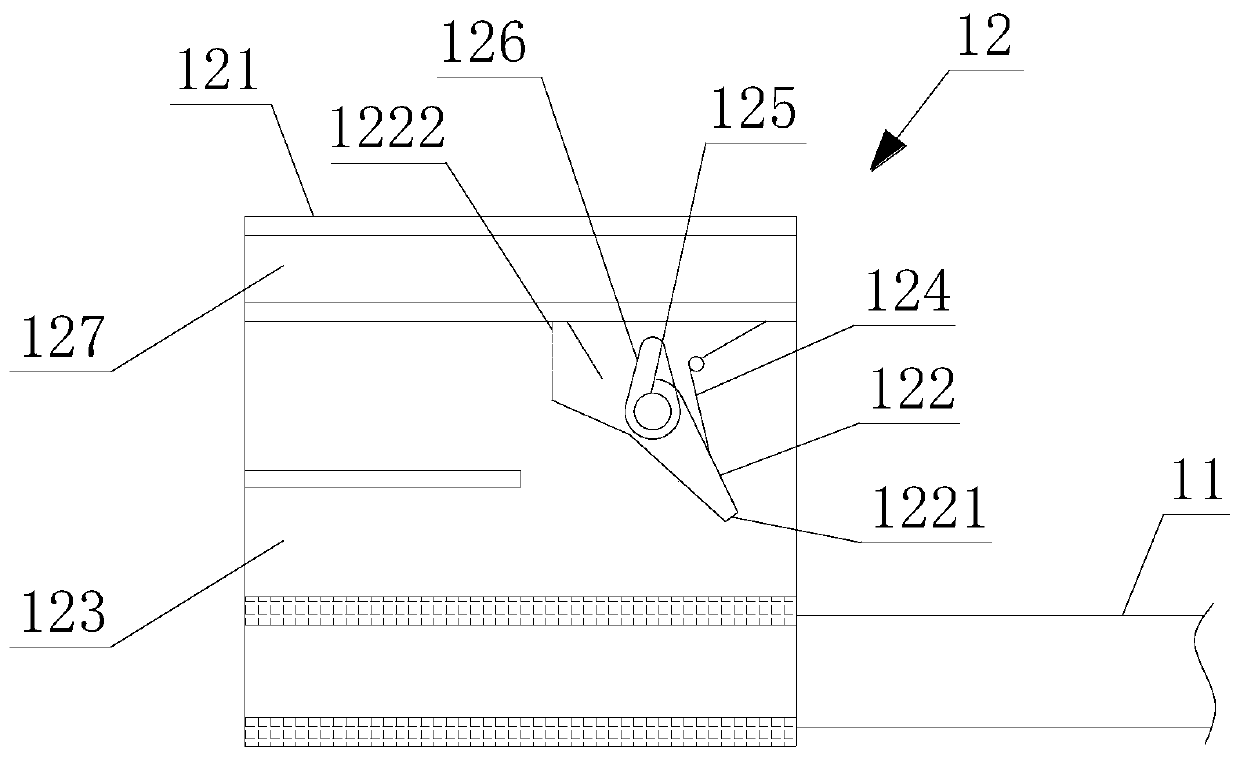

[0047] The lock head 12 is fixed on the end of the belt body 11 away from the toothed area 111 . The lock head 12 is provided with a lock catch 122 . In the locked or unlocked state, in the locked state, the toothed area 111 can only pass the lock head 12 in one direction in the direction of tightening the tie, and in the unlocked state, the toothed area 111 can pass through the lock head 12 in both directions.

[0048] Wherein, the length of the clamping area 111 depends on the situation, and the longer the clamping area 111 is, the larger the range of diameters applicable to the closing cable tie 1 is. ...

Embodiment 2

[0057] like Figure 7 As shown, the tightening device 2 for tightening a cinch tie provided in this embodiment includes a handle 21 , a ratchet mechanism 22 and a connecting member 23 .

[0058] One end of the handle 21 is provided with a mounting portion 211 , and the other end is provided with an anti-slip texture 212 .

[0059] The ratchet mechanism 22 is mounted on the mounting portion 211 of the handle 21; the ratchet mechanism 22 includes a ratchet wheel 221 and a pawl 222. The ratchet wheel 221 is rotatably mounted on the mounting portion 211 through a rotating shaft 223. The latching teeth area 111 of the 221 is engaged, and the pawl 222 is installed on the mounting portion 211 on the side of the ratchet wheel 221 , and the pawl 222 is used to limit the ratchet wheel 221 to rotate only in one direction.

[0060] The connecting member 23 is used to keep the tightening device 2 and the closing strap 1 relatively fixed.

[0061] In a more specific structure, the ratchet...

Embodiment 3

[0068] This embodiment provides a cable tie kit with a tightening device, which includes a closing cable 1 and a tightening device 2; wherein the closing cable 1 is the closing cable in Embodiment 1, and the tightening device 2 is an embodiment 2 of the closing device.

[0069] Among them, the tooth 1111 of the tooth area 111 of the closing tie 1 matches with the tooth of the ratchet wheel 22 of the tightening device 2 and can be engaged with each other; 231 can be snapped into the hanging slot 127 without loosening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com