High-precision large-format solid projection 3D printing system and printing method thereof

A stereoscopic projection and 3D printing technology, applied in the field of 3D printing, can solve problems affecting printing speed and cost economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific technical solutions of the present invention are described in conjunction with the examples.

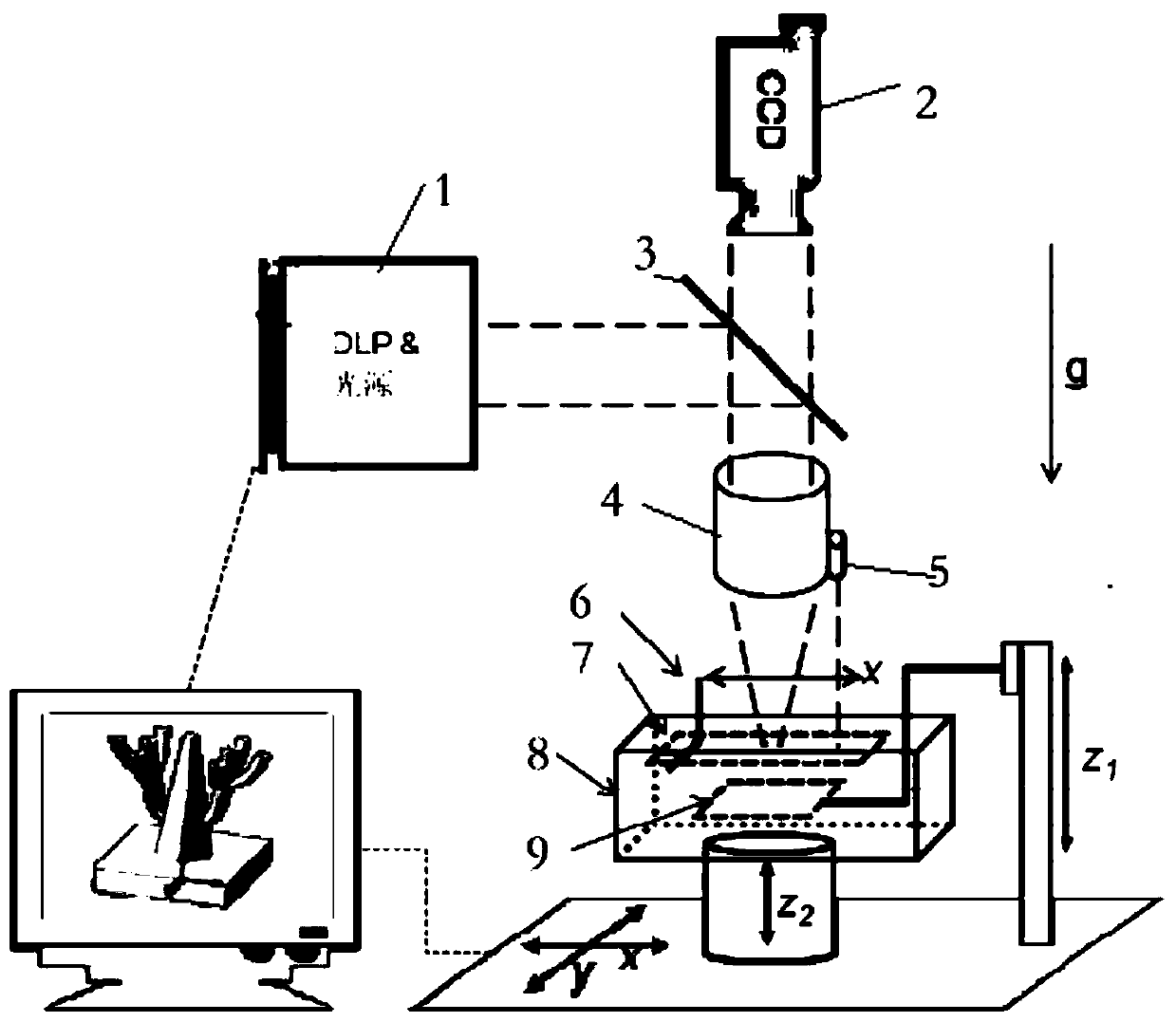

[0027] Such as figure 1 As shown, a high-precision large-format stereoscopic projection 3D printing system includes a DLP optical machine 1 with a light source, a projection lens 4, and a resin tank 8;

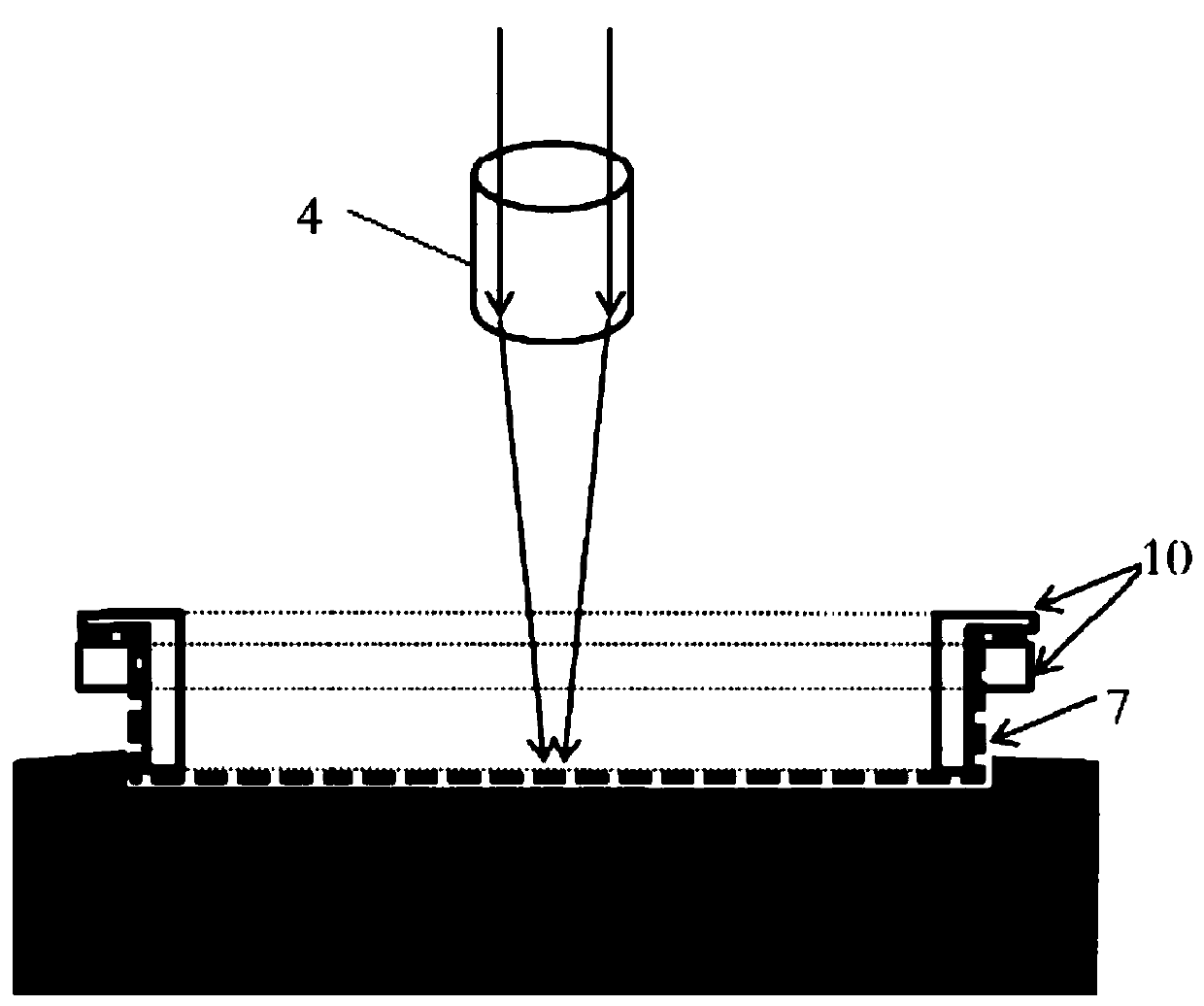

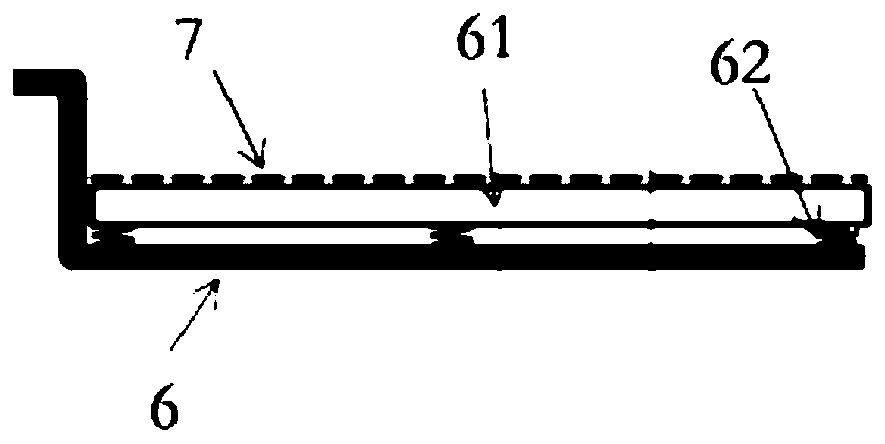

[0028] The optical path projected by the DLP optical machine 1 is reflected and projected into the projection lens 4 through the film beam splitter 3, and the projection lens 4 is projected onto the interface between the film 7 and the resin in the resin tank 8;

[0029] The thin-film beamsplitter 3 can also be a millimeter-level thick beamsplitter lens made of glass, but for the wavelength of light used, one side of the lens should be coated with a reflective film, while the other side should be coated with an anti-reflective coating to eliminate ghosting.

[0030] One side of the projection lens 4 is provided with a laser displacement gauge 5;

[0031] One sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com