Water-cooled high-power electron cyclotron resonance heating system direct current blocking device

A technology of electron cyclotron resonance and heating system, which is applied in the microwave field and can solve the problems that the DC blocker cannot be used and the microwave leakage cannot be effectively prevented.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

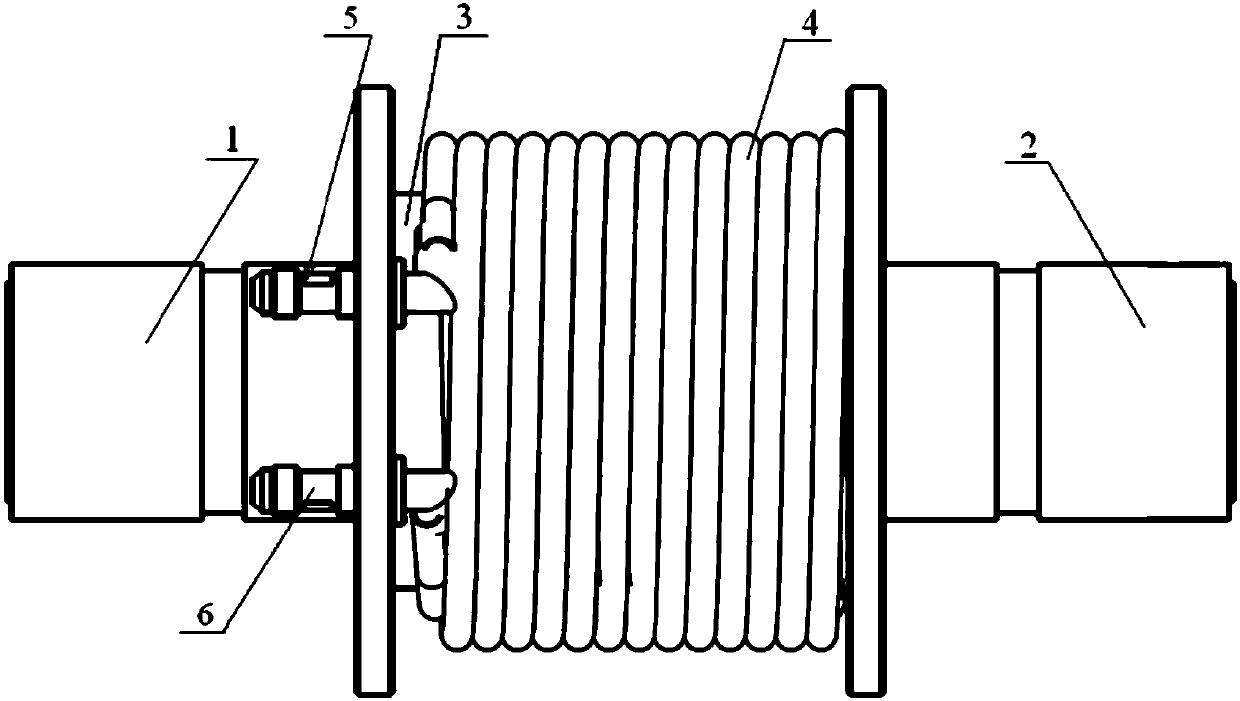

[0024] Such as figure 1 As shown, the straight blocker includes two straight blocker corrugated waveguides (corrugated waveguide A1, corrugated waveguide B2), an insulating sleeve 3, a cooling water pipe 4, a cooling water inlet joint 5 and a cooling water outlet joint 6.

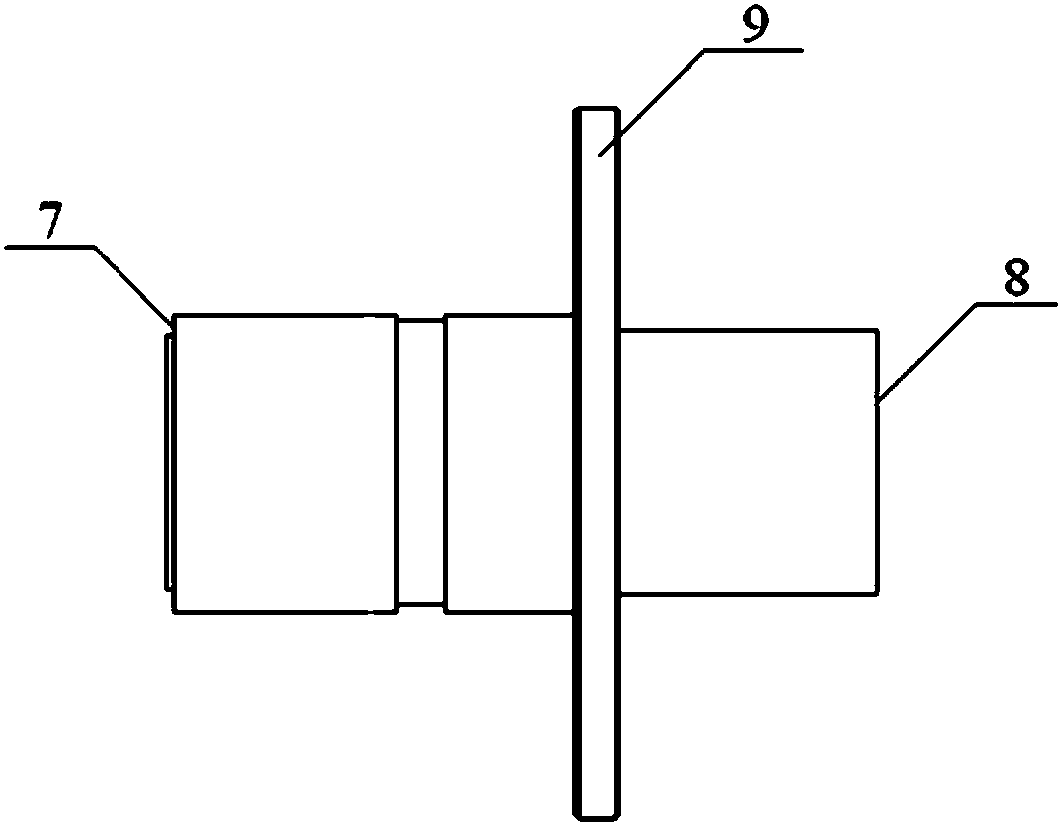

[0025] Such as Figure 2a As shown, the corrugated waveguide A1 or the corrugated waveguide B2 is processed with an insulating sleeve connecting flange 9, bounded by the insulating sleeve connecting flange 9, the inner end face of the corrugated waveguide A1 or the corrugated waveguide B2 is the waveguide docking end face 9, and the outer end face The end face is the waveguide sealing end face 7 .

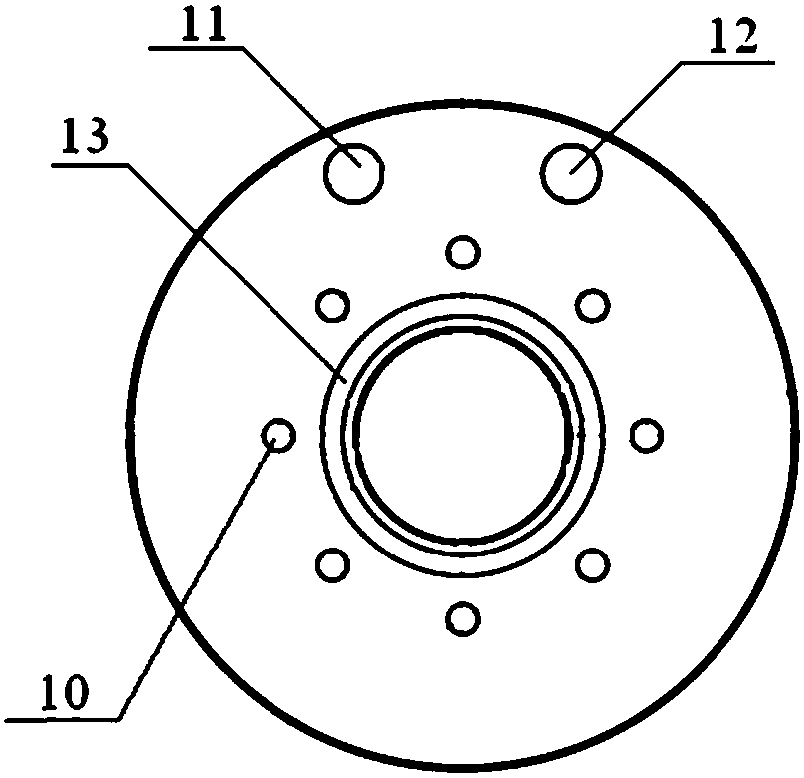

[0026] The inner part of the corrugated waveguide A1 or the corrugated waveguide B2 is located inside the insulating sleeve 3, and the connecting flange 9 of the insulating sleeve is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com