Solar module fault detection system and method

A solar module and fault detection technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as heavy workload, abnormal operation of solar power generation system, solar module damage, etc., to achieve improved safety, convenient detection and safety, convenience carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

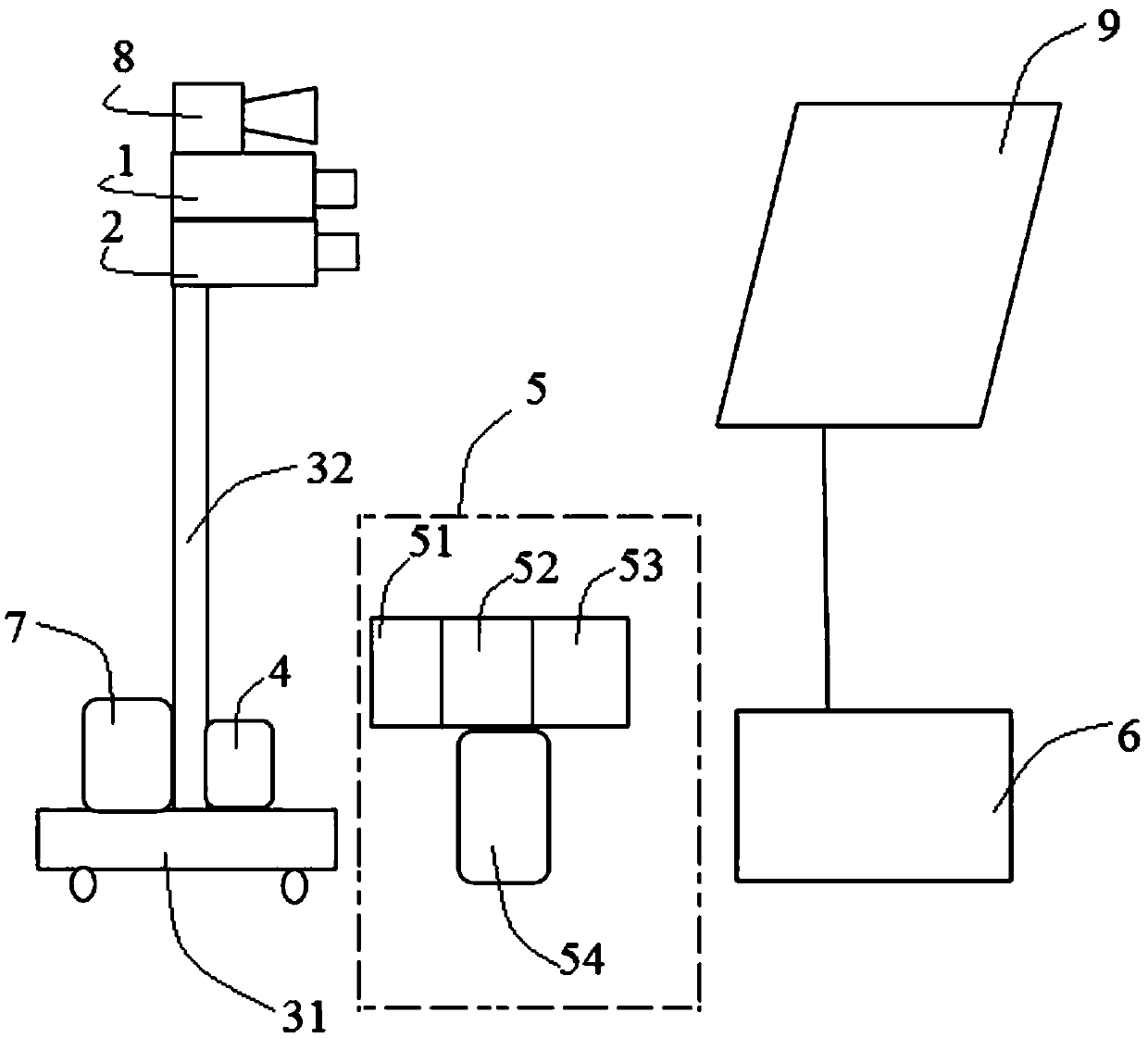

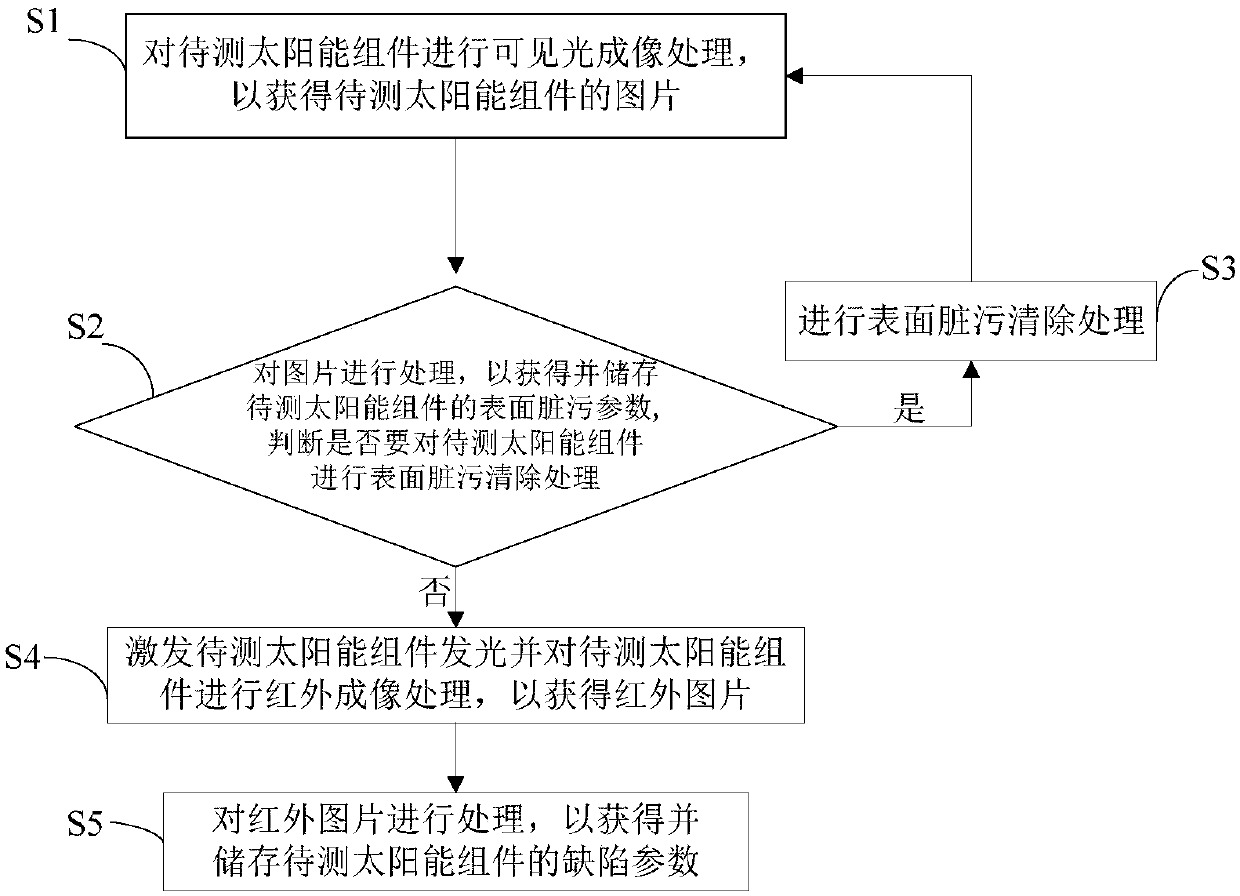

[0079] (1) In the absence of sunlight, use the visible light source module 8 to provide light to the surface of the solar module 9 to be tested, and adjust the three-axis adjustable mobile mechanical module, visible light imaging module 1 and infrared imaging through the control module 4 The position of the module 2 relative to the solar component 9 to be tested is such that the camera of the visible light imaging module 1 is perpendicular to the surface of the solar component 9 to be tested, and the visible light imaging module 1 is used to image the solar component 9 to be tested to obtain a picture of the solar component 9 to be tested;

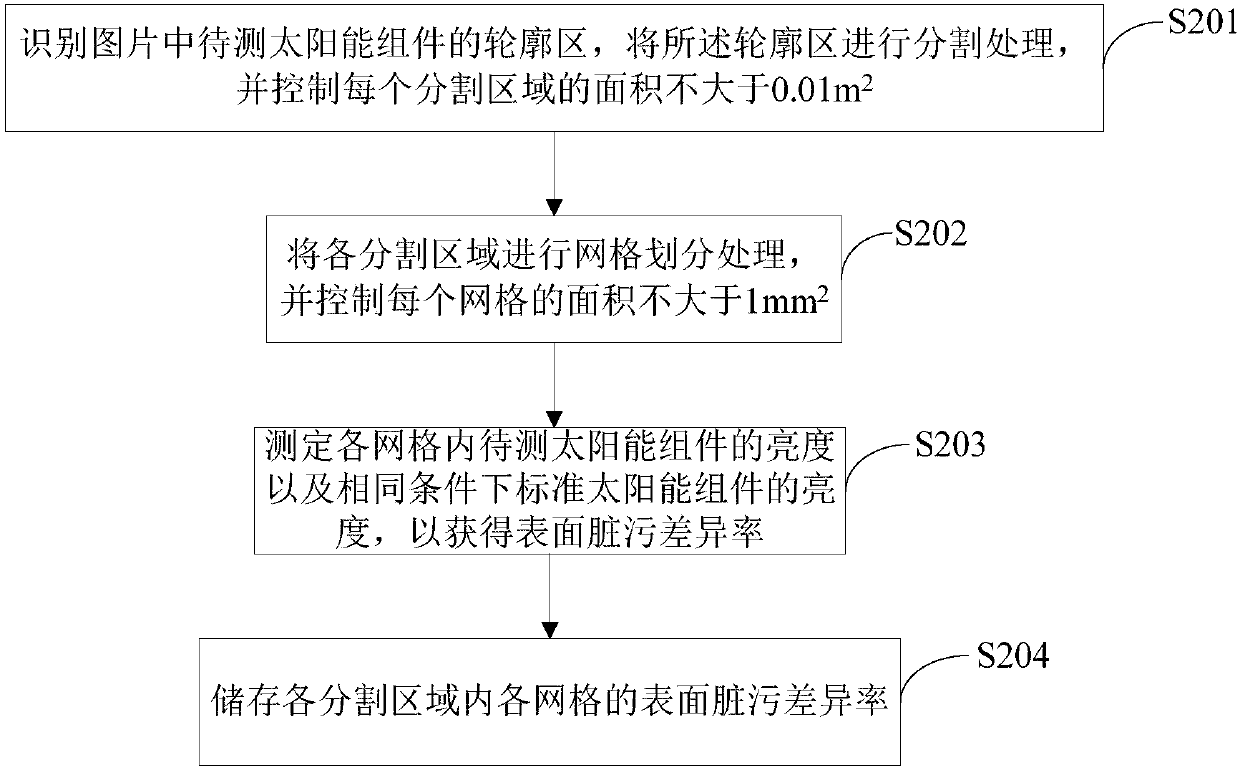

[0080] (2) Process the picture obtained in step (1) to obtain and store the surface dirt parameters of the solar module 9 to be tested, including:

[0081] (S1) The picture obtained in step (1) is transmitted to the picture analysis device 52 through the picture transmission device 51, and the outline area of the solar module 9 to be test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com