Rapid collecting device for deep soil

A technology of collecting device and deep soil, applied in the direction of sampling device, etc., can solve problems such as inability to collect soil, and achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

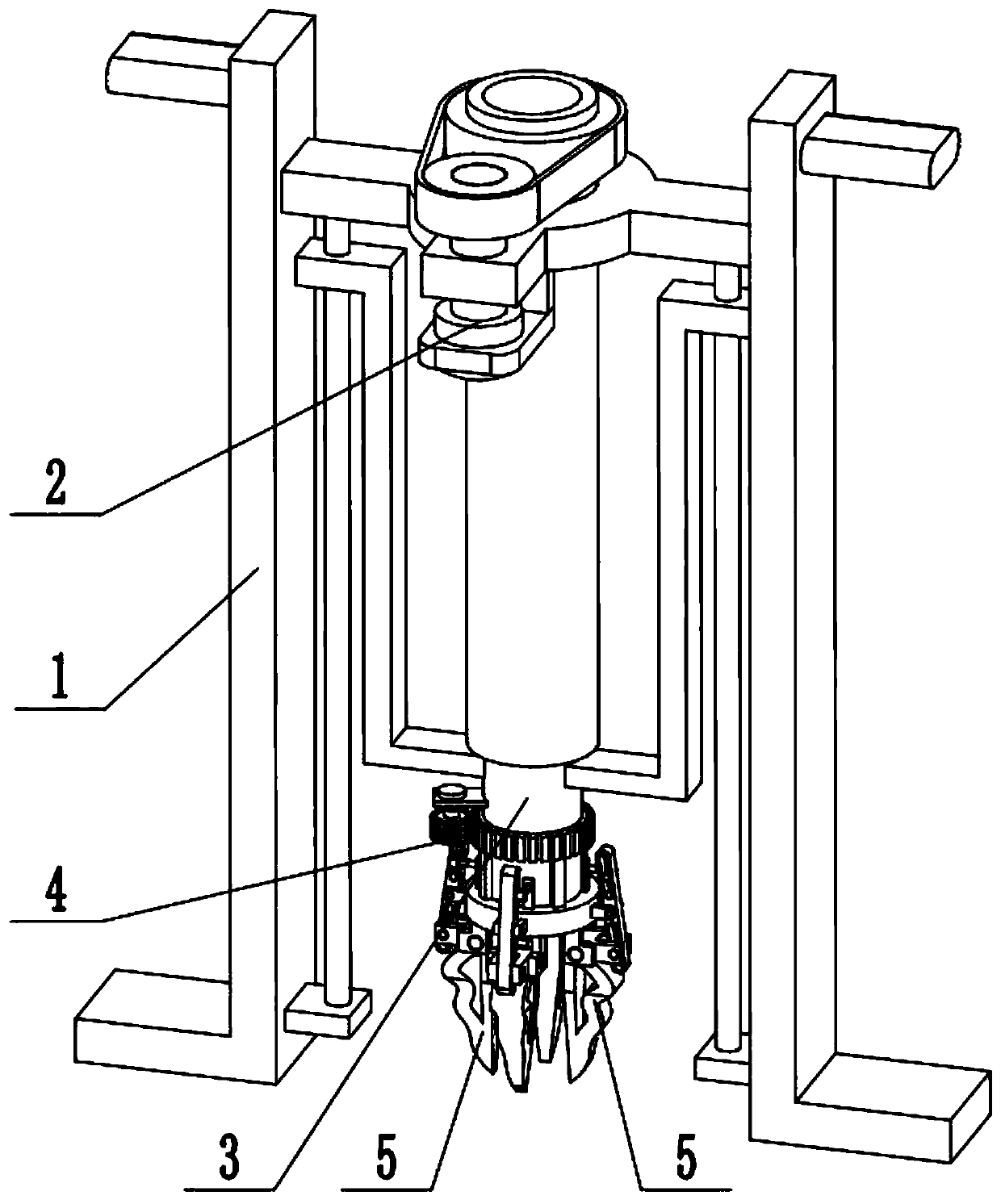

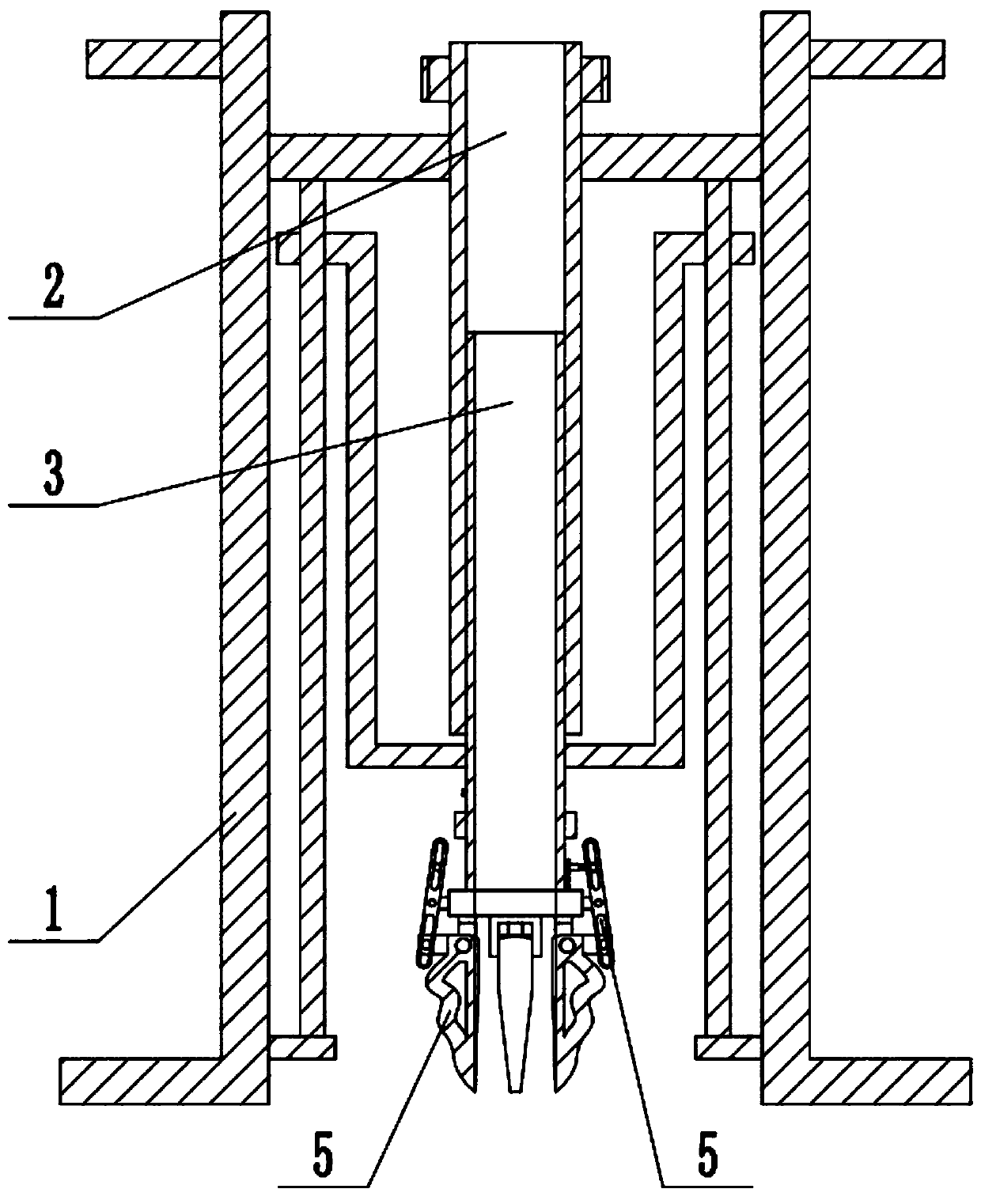

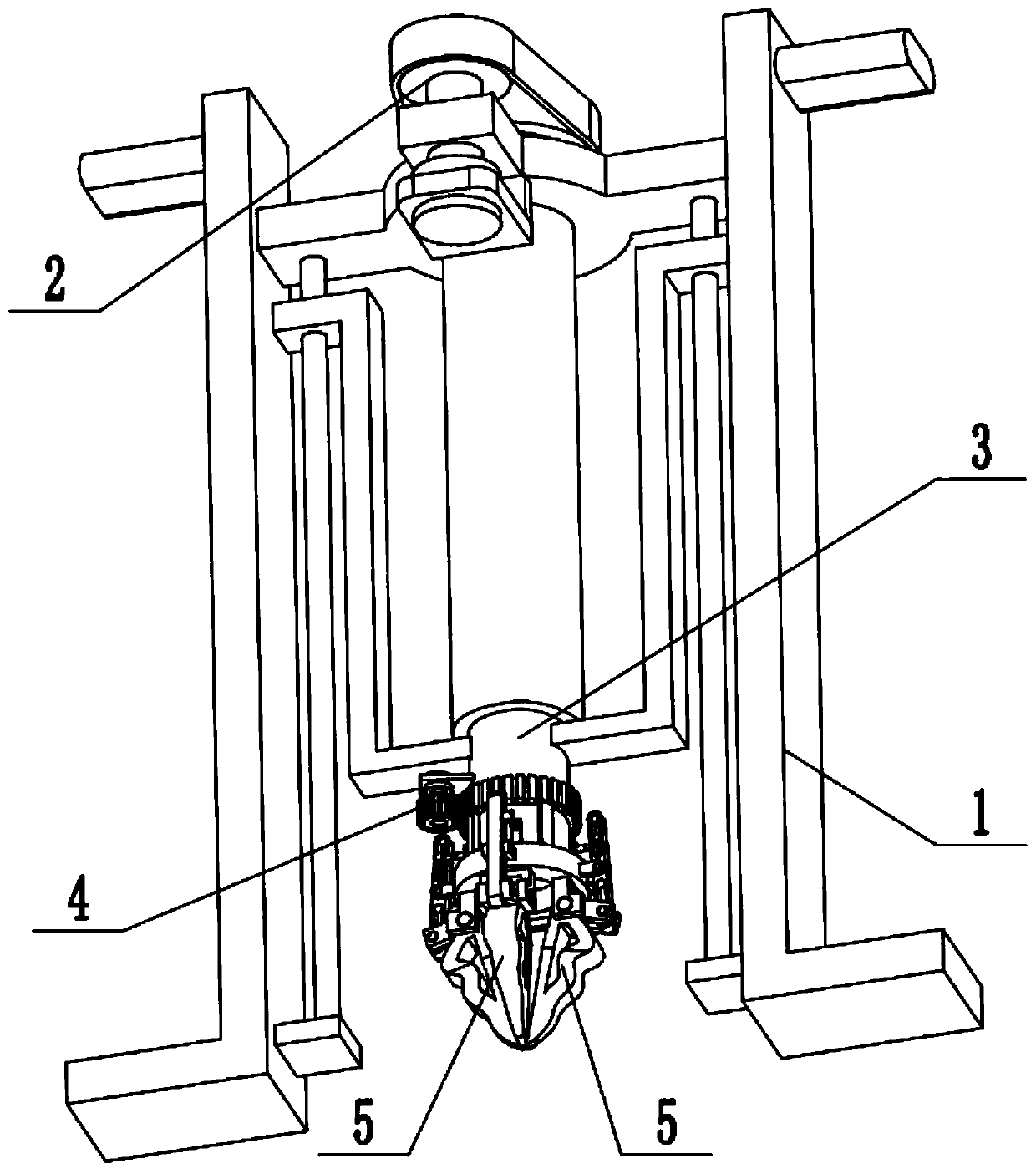

[0028] Combine below Figure 1-11 Illustrating this embodiment, a deep soil rapid collection device includes a sampling frame 1, a sampling depth control mechanism 2, a soil sampling cylinder assembly 3, a drill bit base assembly 4 and a drill bit assembly 5. The sampling depth control mechanism 2 is connected to the The upper end of the sampling rack 1, the two ends of the soil sampling cylinder assembly 3 are respectively connected to the two ends of the sampling rack 1 by sliding fit, and the middle end of the soil sampling cylinder assembly 3 is connected to the sampling depth control mechanism 2 through threads. 4 is connected to the lower end of the soil sampling cylinder assembly 3, four drill bit assemblies 5 are provided, and the four drill bit assemblies 5 are evenly arranged around the lower end of the drill bit base assembly 4. When the present invention is in use, place the sampling rack 1 on the geological surface to be sampled, so that the position to be sampled...

specific Embodiment approach 2

[0029] Combine below Figure 1-11 Illustrating this embodiment, the sampling rack 1 includes a horizontal frame plate 1-1, an L-shaped support plate 1-2, a handle bar 1-3, a base plate 1-4 and a guide rod 1-5; a horizontal frame plate Both ends of 1-1 are fixedly connected with an L-shaped support plate 1-2, the outer sides of the upper ends of the two L-shaped support plates 1-2 are respectively fixed with a hand lever 1-3, and two L-shaped support plates 1-2 The inner side of the lower end is fixedly connected to a base plate 1-4 respectively, the two base plates 1-4 are respectively fixedly connected to a guide rod 1-5, and the upper ends of the two guide rods 1-5 are fixedly connected to the horizontal frame plate 1-1. superior. When the sampling rack 1 is in use, the two grip bars 1-3 are held with both hands, and the lower ends of the two L-shaped support plates 1-2 are stepped on with both feet to ensure the stability of the device during operation.

specific Embodiment approach 3

[0030] Combine below Figure 1-11Illustrating this embodiment, the sampling depth control mechanism 2 includes an internal thread sleeve 2-1, a depth control motor 2-2, a transmission shaft 2-3, a driving pulley 2-4 and a driven pulley 2-5; The upper end of the inner threaded sleeve 2-1 is rotatably connected to the middle end of the horizontal frame plate 1-1 through the bearing with seat, and the upper end of the inner threaded sleeve 2-1 is fixedly connected to the driven pulley 2-5, and the driven pulley 2 -5 is located at the upper end of the horizontal frame plate 1-1, the driven pulley 2-5 is connected with the driving pulley 2-4 through a belt drive, the driving pulley 2-4 is fixedly connected to the transmission shaft 2-3, and the depth is controlled The output shaft of the motor 2-2 is connected to the transmission shaft 2-3 through a coupling, and the depth control motor 2-2 is fixedly connected to the horizontal frame plate 1-1 through a motor frame. When the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com