Underwater blasting priming device and use method

A technology of detonating device and mounting plate, which is applied in the direction of blasting, blasting barrels, weapon accessories, etc., can solve the problems of high misfire rate, hinder normal operation, hinder navigation, etc., achieve high ignition reliability, controllable firing time, and prevent detonators The effect of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

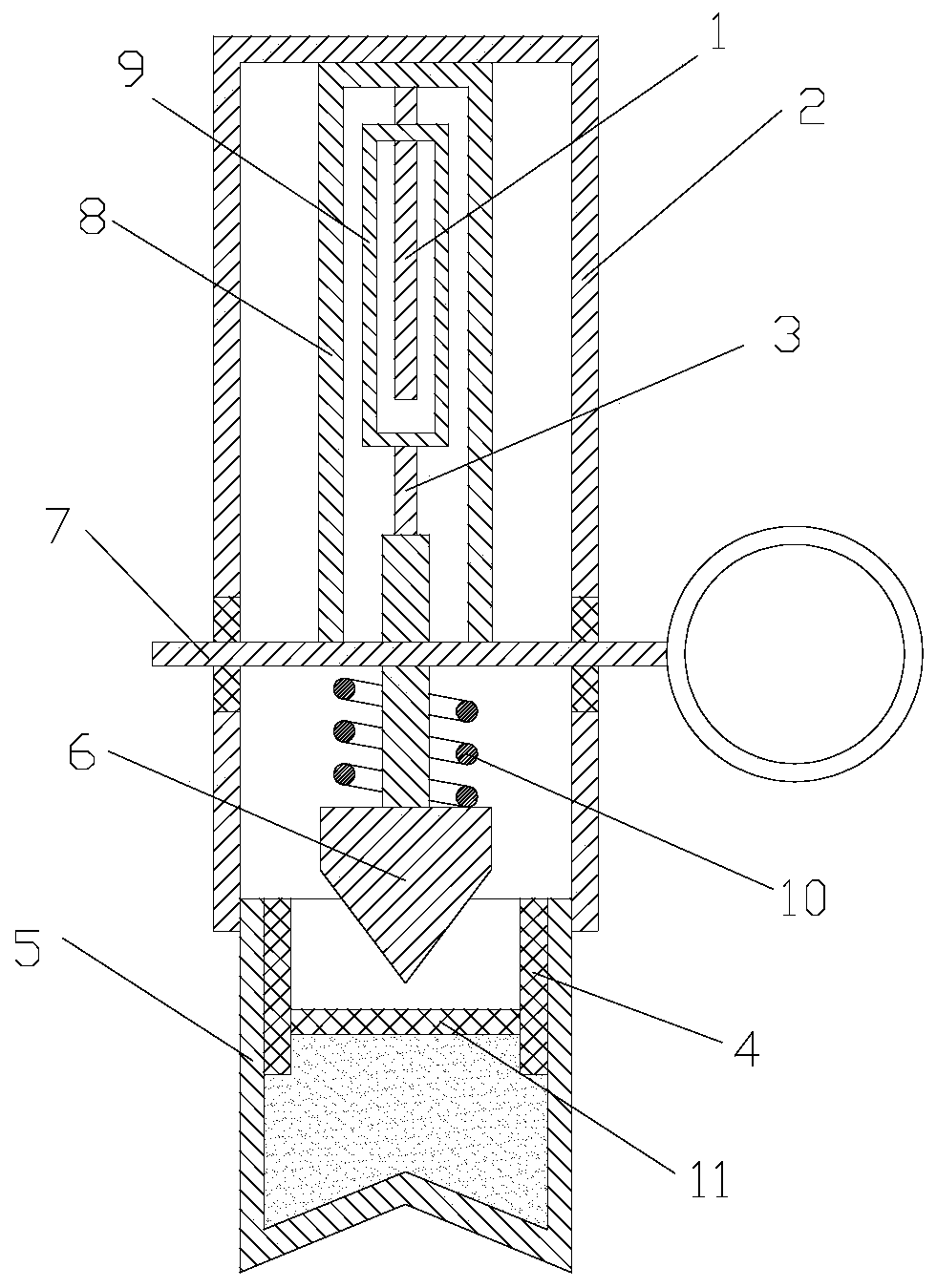

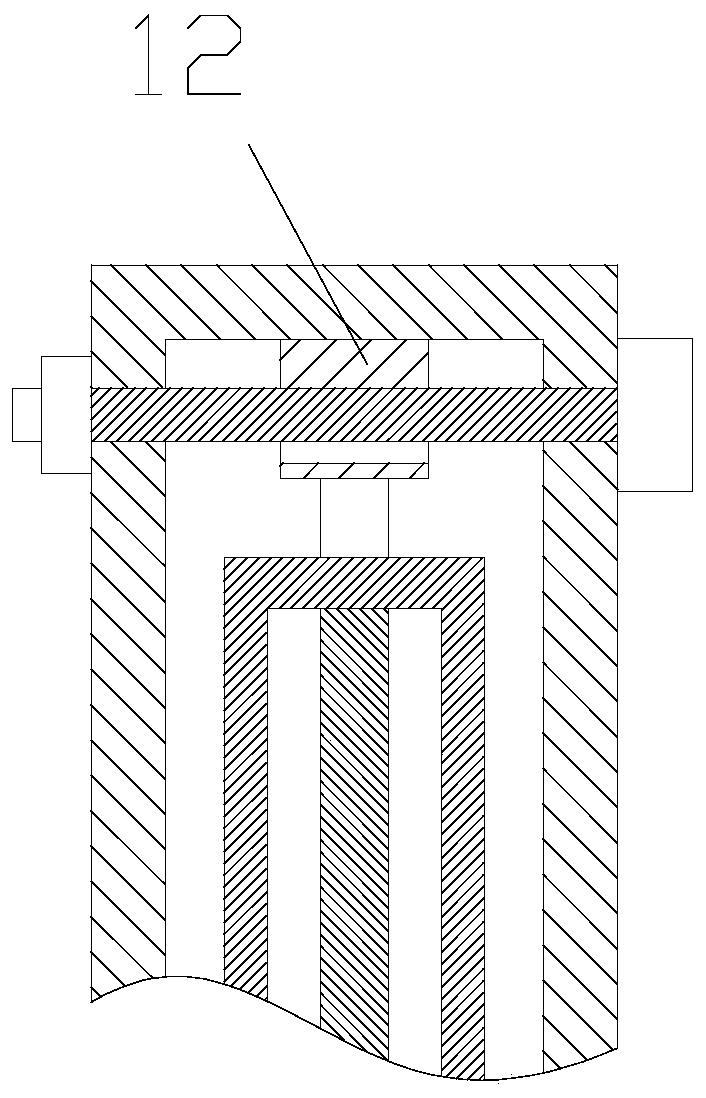

[0022] like Figure 1 to Figure 3 As shown, the underwater blasting detonating device of the present invention includes an outer sleeve 2, an inner sleeve 8 and a detonator shell 5, the inner sleeve 8 is installed in the outer sleeve 2, and a soft The metal buffer sheet 1 is embedded with a rigid metal frame 9 in the soft metal buffer sheet 1, and the rigid metal frame 9 is connected with the firing pin 6 through the connecting rod 3, and a safety pin 7 is inserted horizontally on the outer sleeve 2, and the safety pin 7 The rubber ring 4 is connected with the outer sleeve 2, the safety pin 7 passes through the firing pin 6, and the firing pin 6 is covered with a firing pin spring, the detonator shell 5 is connected with the outer sleeve 2 through threads, and a Rubber ring 4, waterproof membrane 11 is installed on rubber ring 4, and the bottom of waterproof membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com