Efficient two-stage air compressor and control method thereof

An air compressor and two-stage compression technology, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of high cost of the two-stage screw host, high rated current of the motor, and large starting torque, etc., and achieves a simple structure , The effect of small screw force and low exhaust pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

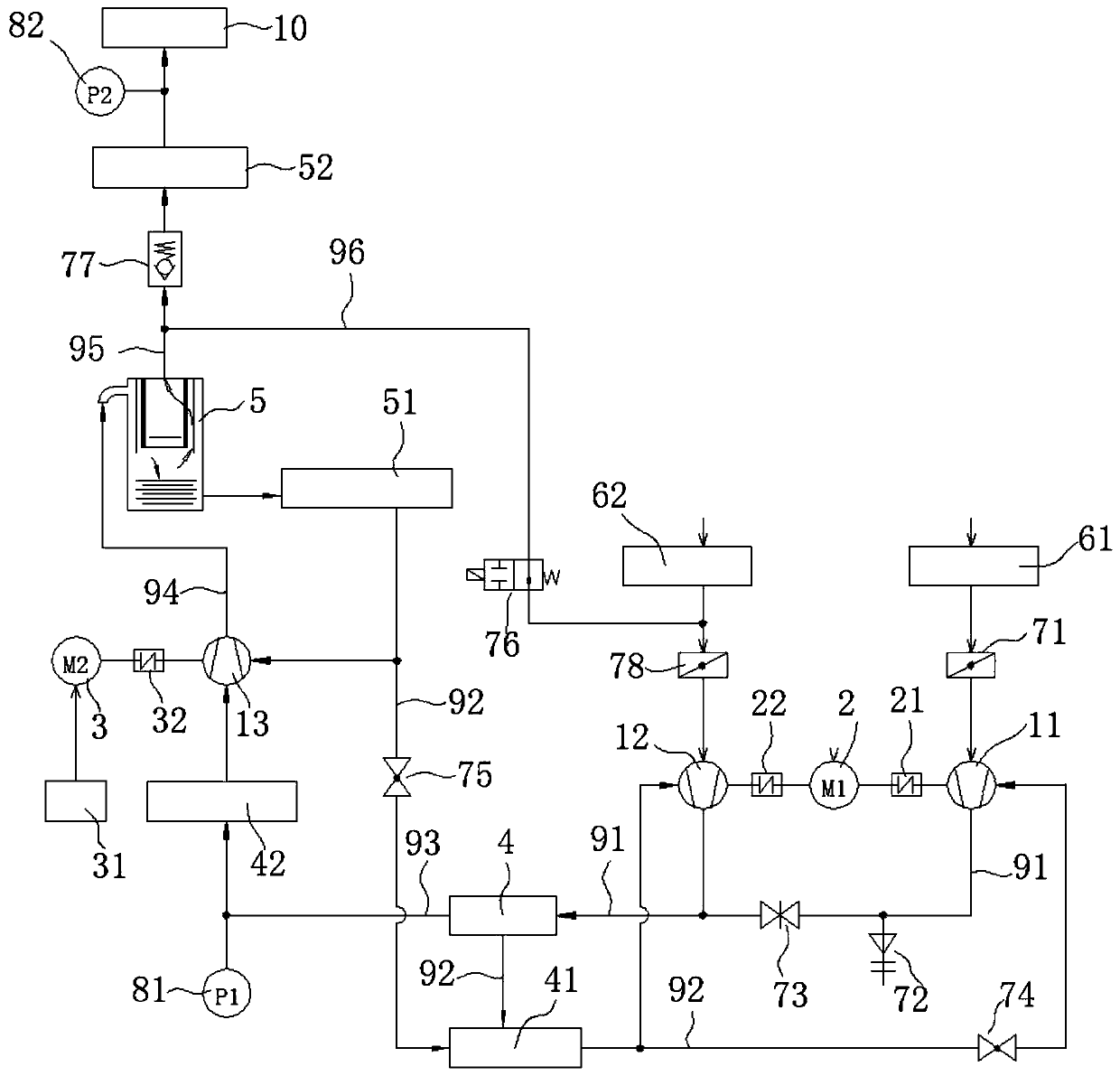

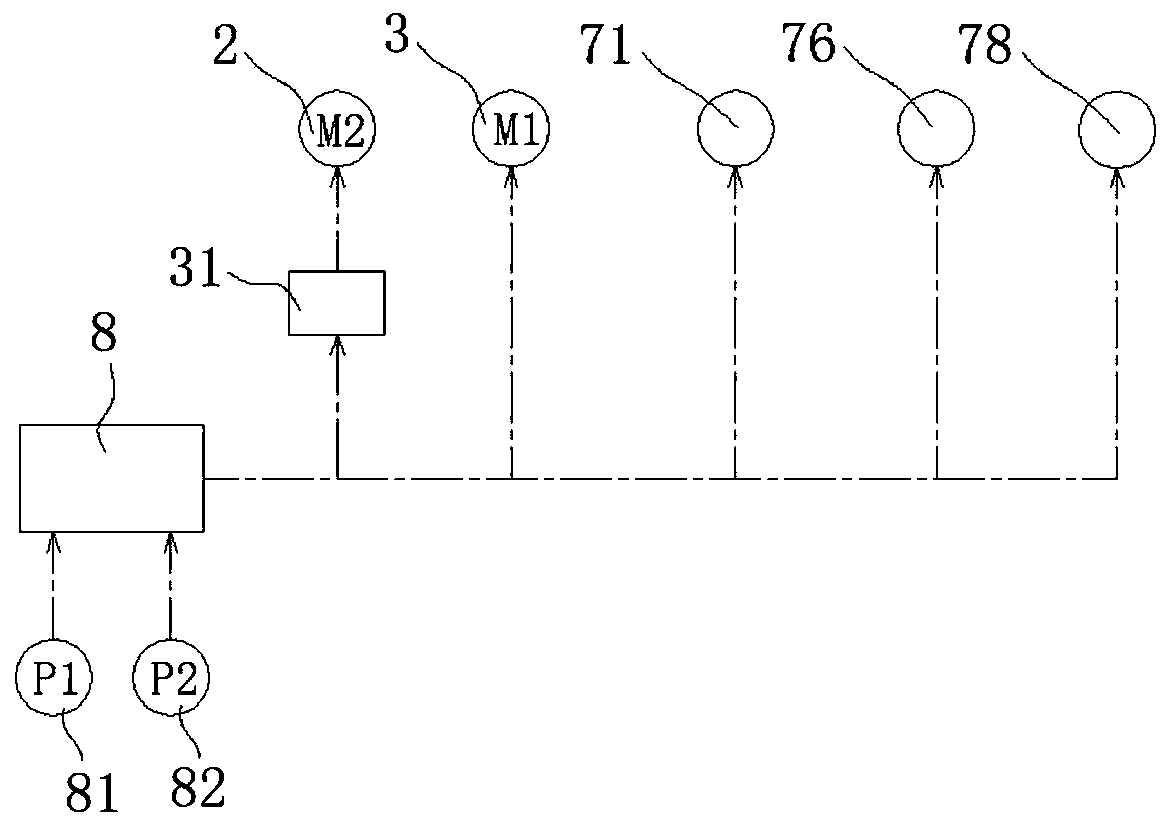

[0055] This embodiment is basically as figure 1 Shown: high-efficiency two-stage air compressor, including air intake system, three compressor hosts, primary oil-gas separation system, secondary oil-gas separation system, primary oil cooling system 41, secondary oil cooling system 51, primary air cooling system 42 and secondary air cooling system 52 .

[0056] The compression hosts are two primary compression hosts and a secondary compression host 13, both of which are screw compressors, and the two primary compression hosts are the first primary compression host 11 and the second primary compression host 12 respectively. The first-stage compression main engine 11 is connected to the first-stage motor 2 through the first coupling 21, and the first coupling 21 is a separate clamping type elastic coupling, so that the first-stage compression main engine 11 and the first-stage motor 2 Detachable connection. The first-stage motor 2 is a motor with dual output shafts, and the oth...

Embodiment 2

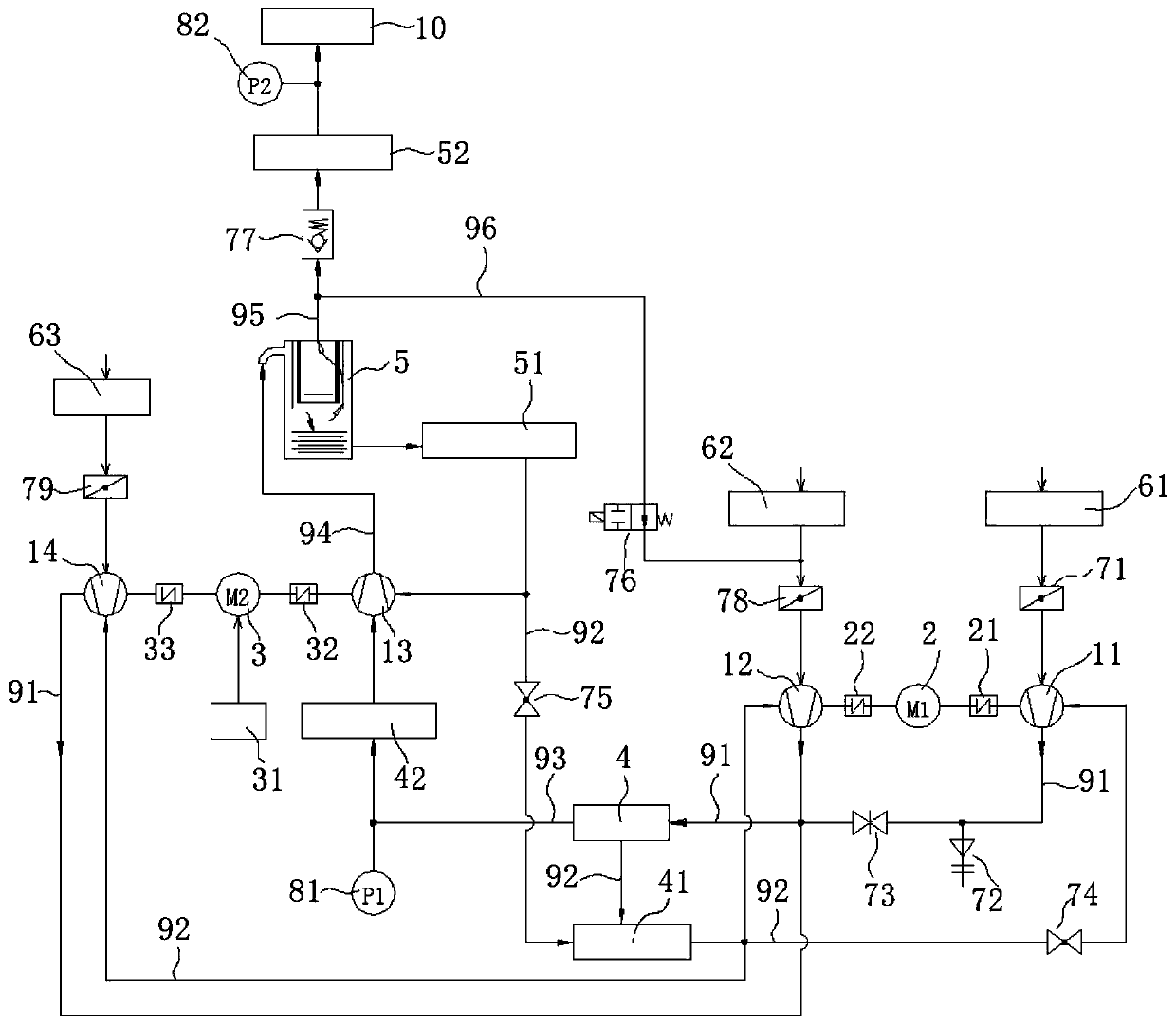

[0080] The difference between this embodiment and Embodiment 1 is: there are three primary compression hosts in this embodiment, such as image 3 As shown, in addition to setting the first-stage compression host 11 and the second-stage compression host 12 in Embodiment 1, a third-stage compression host 14 is also provided. In this embodiment, the second-stage motor 3 is a dual-output shaft frequency conversion motor, one output shaft is connected with the second-stage compressor host 13, and the other output shaft is detachably connected with the third-stage compressor host 14. Specifically, the third one can be made through the fourth shaft coupling 33 or a belt transmission mechanism. The primary compressor 14 is detachably connected to the secondary motor 3; thus the secondary motor 3 simultaneously drives the secondary compressor 13 and the third primary compressor 14 to rotate to compress air.

[0081] The air inlet of the third-stage compressor host 14 is also connected ...

Embodiment 3

[0085] The difference between this embodiment and the above two embodiments is that there are two first-level compression hosts in this embodiment, which are the second-level compression host 12 and the third-level compression host 14, wherein the second level The main compressor 12 is connected to the first-stage motor 2 through the second coupling 22 , and the third-stage main compressor 14 is connected to the other output shaft of the second-stage motor 3 through the fourth coupling 33 . Its working process is the same as that of the above-mentioned embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com