A structural mode of urban underground comprehensive utility corridor

A technology for integrated pipe gallery and pipe gallery, applied in underwater structures, infrastructure engineering, construction, etc., can solve the problems of high transportation cost, large transportation space, large volume, etc., achieve strong heat dissipation effect, and enhance connection firmness , the effect of high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

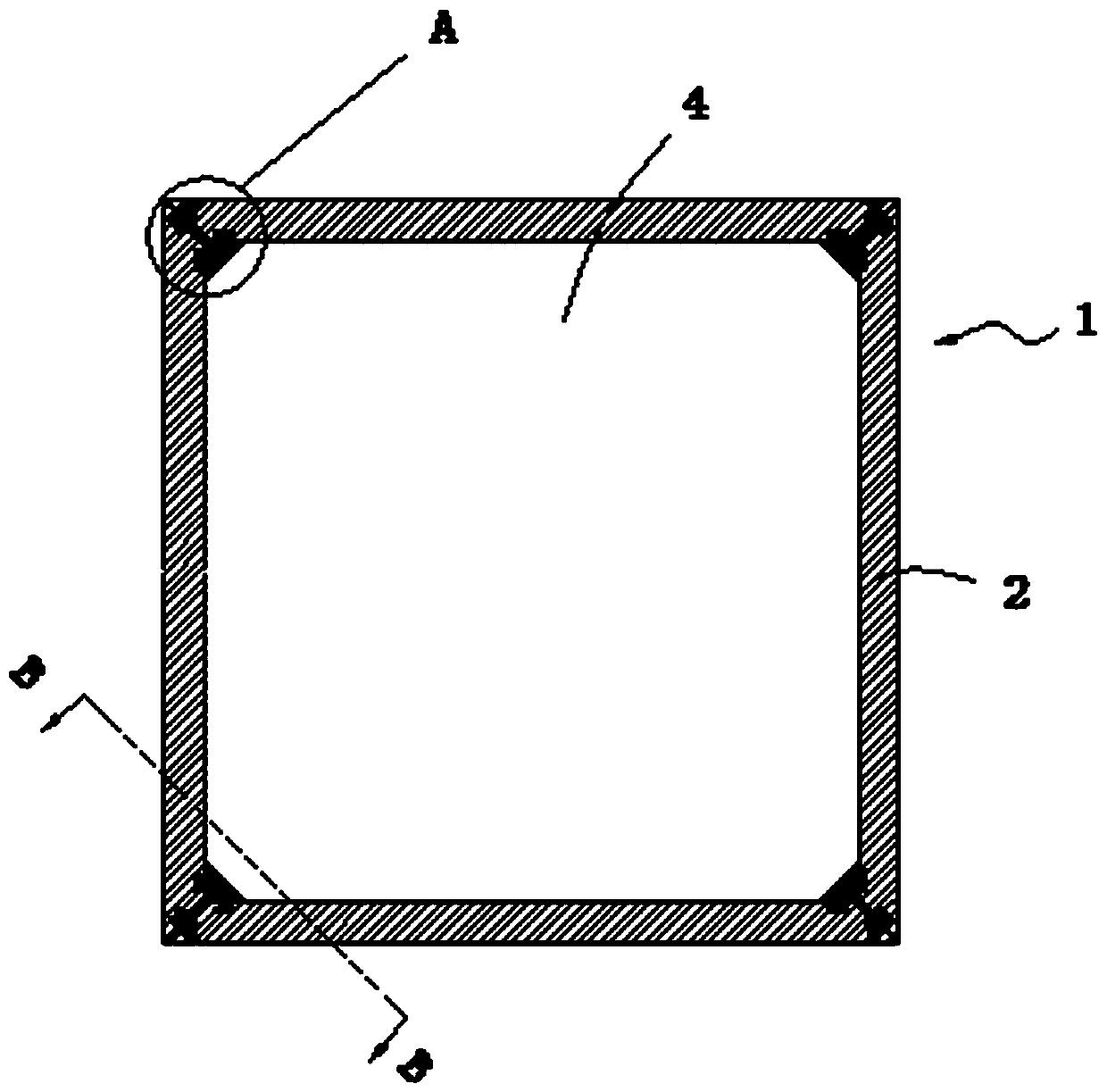

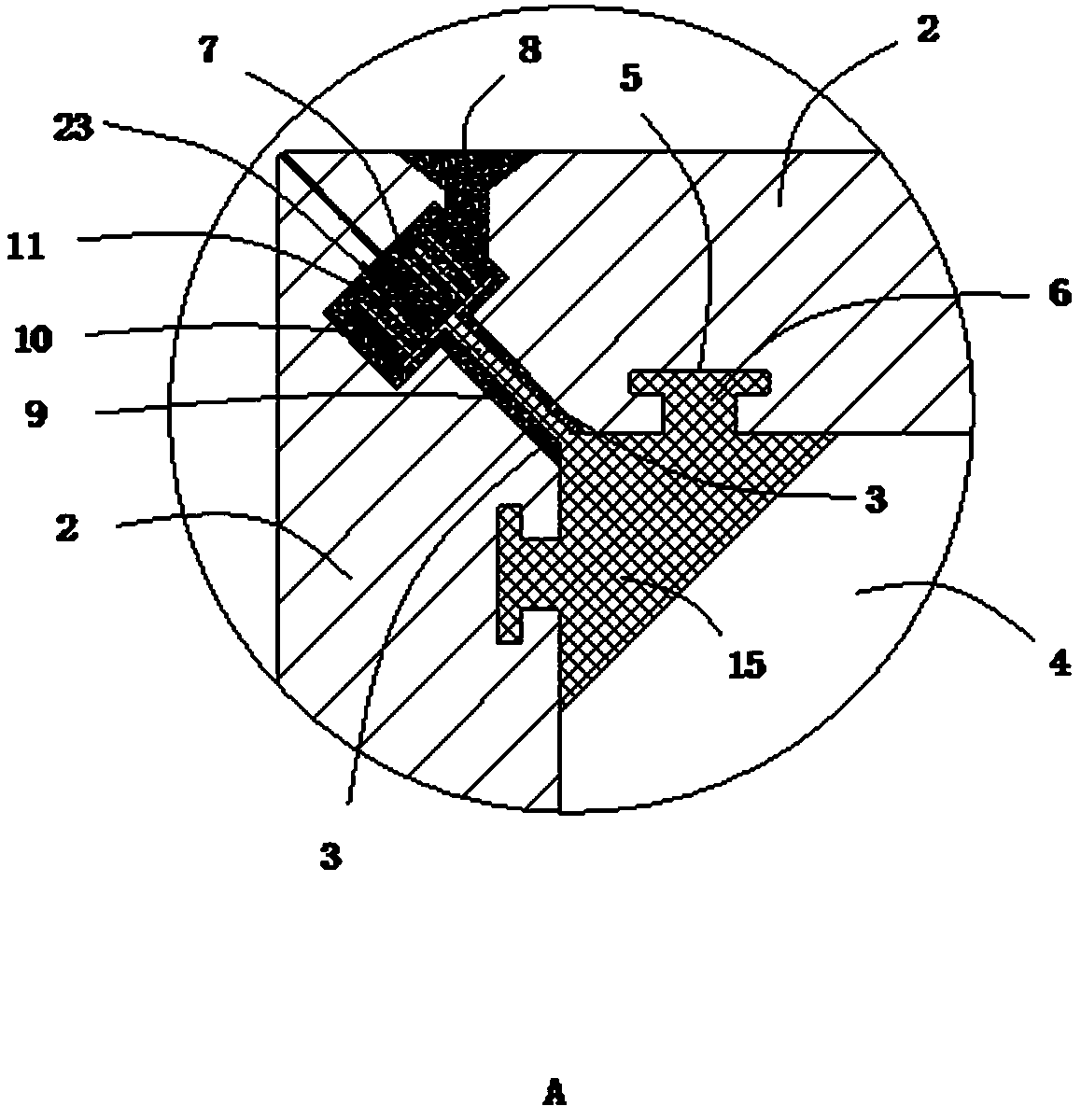

[0046] The structure of an urban underground comprehensive pipe gallery disclosed by the present invention includes a pipe gallery body 1, and the pipe gallery body 1 includes at least three pipe gallery side panels 2. In this embodiment, the pipe gallery body 1 on each The number of gallery side panels 2 is four pieces, and the shape of each tube gallery side panel 2 is a square plate. The tubular structure of the chamber 4, the inner space of the accommodating chamber 4 in the pipe gallery body 1 is a square channel.

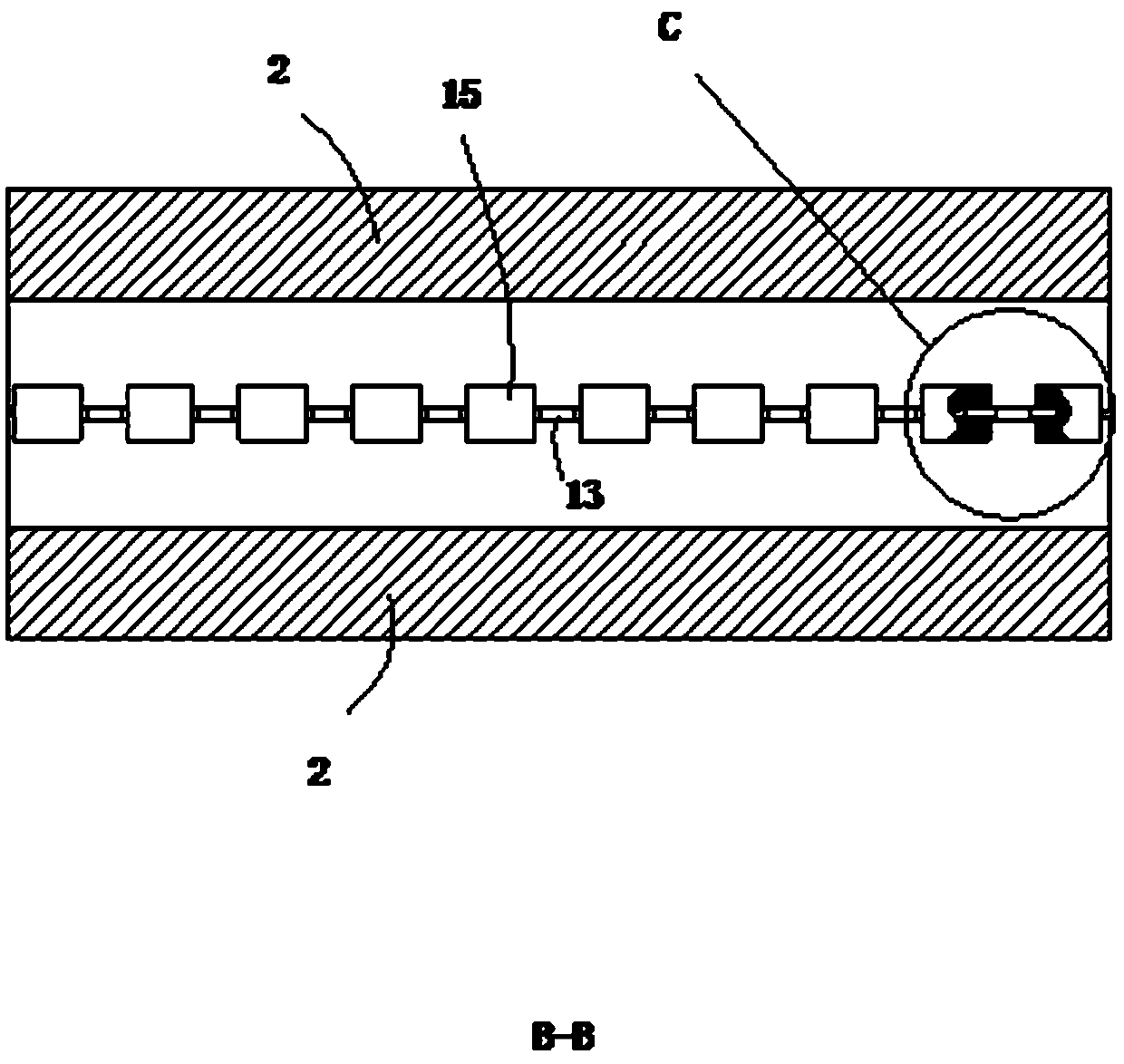

[0047] A number of connection blocks 15 are arranged in the accommodation chamber 4 in the pipe gallery body 1. The edge of the adjacent two pipe gallery side panels 2 is the conflicting side 3, and the connection blocks 15 are respectively distributed on the four sides of the pipe gallery body 1. On the corner, a T-shaped chute 5 is provided on the inner wall of the pipe gallery side plate 2 close to the accommodation chamber 4, and the length direction of th...

Embodiment 2

[0055] The number of pipe gallery bodies 1 in this embodiment is at least two, and each pipe gallery body 1 adopts the pipe gallery body 1 structure in Embodiment 1. All pipe gallery bodies 1 are arranged horizontally and parallel to each other, and two adjacent pipe gallery bodies The side plate 2 of the pipe gallery opposite to the gallery body 1 is a cooling plate surface 16, and a cooling gap 17 is left between two adjacent cooling plate surfaces 16; the side plates 2 of the pipe gallery on two adjacent pipe gallery bodies 1 are respectively the second One side plate 19, the second side plate 21, the first side plate 19 is provided with some first slide blocks 20, the second side plate 21 is provided with some second chute 22, the length direction of the second chute 22 is In the vertical direction, several second chute 22 are evenly distributed along the length direction of the pipe gallery body 1 , and the first slider 20 and the second chute 22 are slidably matched one b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com