A welding device for avoiding false soldering and poor contact during circuit board soldering

A technology of poor contact and welding device, applied in the direction of tin feeding device, welding equipment, auxiliary device, etc., to avoid excessive conveying and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Combine below Figure 1-Figure 4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent.

[0018] The present invention relates to a soldering device for avoiding false soldering and poor contact during circuit board soldering. It is mainly used in the soldering process for avoiding false soldering and poor contact. The present invention will be further described below in conjunction with the drawings of the present invention:

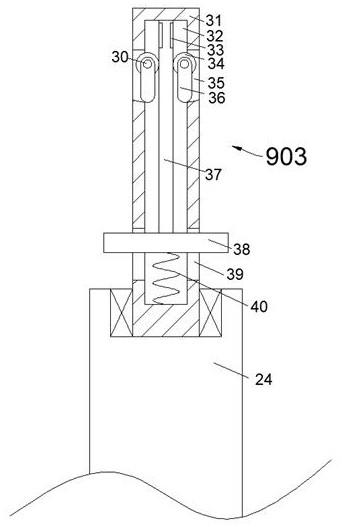

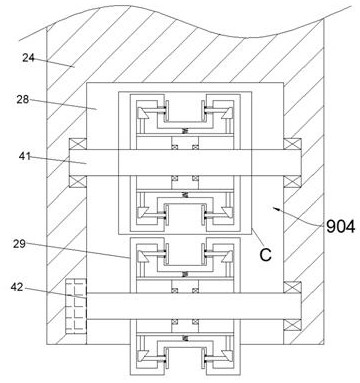

[0019] A welding device for avoiding false soldering and poor contact during circuit board soldering according to the present invention includes a penholder 11, a transmission chamber 13 is provided inside the penholder 11, and a fixed block 20 is provided on the lower end surface of the transmission chamber 13 A wall-contacting device 901 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com