Manufacturing method of electronic jacquard pattern card suitable for k'o-ssu, and pattern card

A technology of electronic jacquard and production method, which is applied in patterns, pattern design devices, textiles, etc. It can solve the problems of not being able to produce Kesi works, not giving intervals and weft insertion connections between intervals, etc., and reducing the number of opening movements , Reduce warp damage and prevent omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

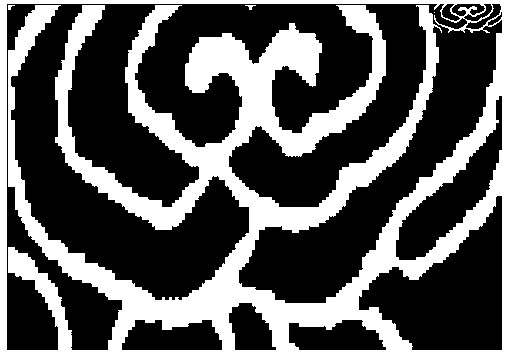

[0039] figure 1 It is a moiré pattern. According to the pattern drawing drawn with a warp density of 24 and a weft density of 40, 148X104 points, the pattern is processed with the help of computer CAD, and the work of drawing the drawing in step 1 is completed. Because the warp density is small and the weft density is large, the pattern is compressed in the weft direction. The small picture in the upper right corner is the original picture, and the actual fabric is produced according to the set warp density and weft density, which is the effect of the small picture without distortion. (Because the attached drawings of the patent application can only be black and white pictures, and black and white pictures cannot represent rich colors, this picture uses black, gray and white patterns to improve the production method of the tapestry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com